Thank you. Now I finally know who I can turn to for baffles with integrated waveguides..

It might be interesting for you as a source of inspiration to have a look at the diyaudio Augerpro thread dealing with printed waveguides for various 21-28 mm tweeters.

It might be interesting for you as a source of inspiration to have a look at the diyaudio Augerpro thread dealing with printed waveguides for various 21-28 mm tweeters.

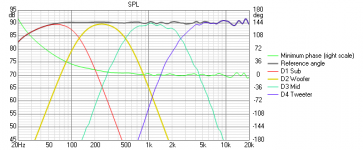

The Magico Q5 is the speaker I was thinking about which has large radius cuts on the front baffle. I attached a simple baffle simulation which confirms the dramatically reduced edge diffraction distortion, and potential for simplier crossover circuits.

Attachments

Thanks all for your positive comments.

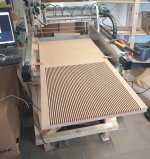

I indeed tried to minimise baffle diffraction. This is the section of how the baffle looks now in design for milling. If needed after measurements I can still sand it a little bit more round.

@Boden, I might be able to help you. Sent me a PM on what you had in mind.

I indeed tried to minimise baffle diffraction. This is the section of how the baffle looks now in design for milling. If needed after measurements I can still sand it a little bit more round.

@Boden, I might be able to help you. Sent me a PM on what you had in mind.

Attachments

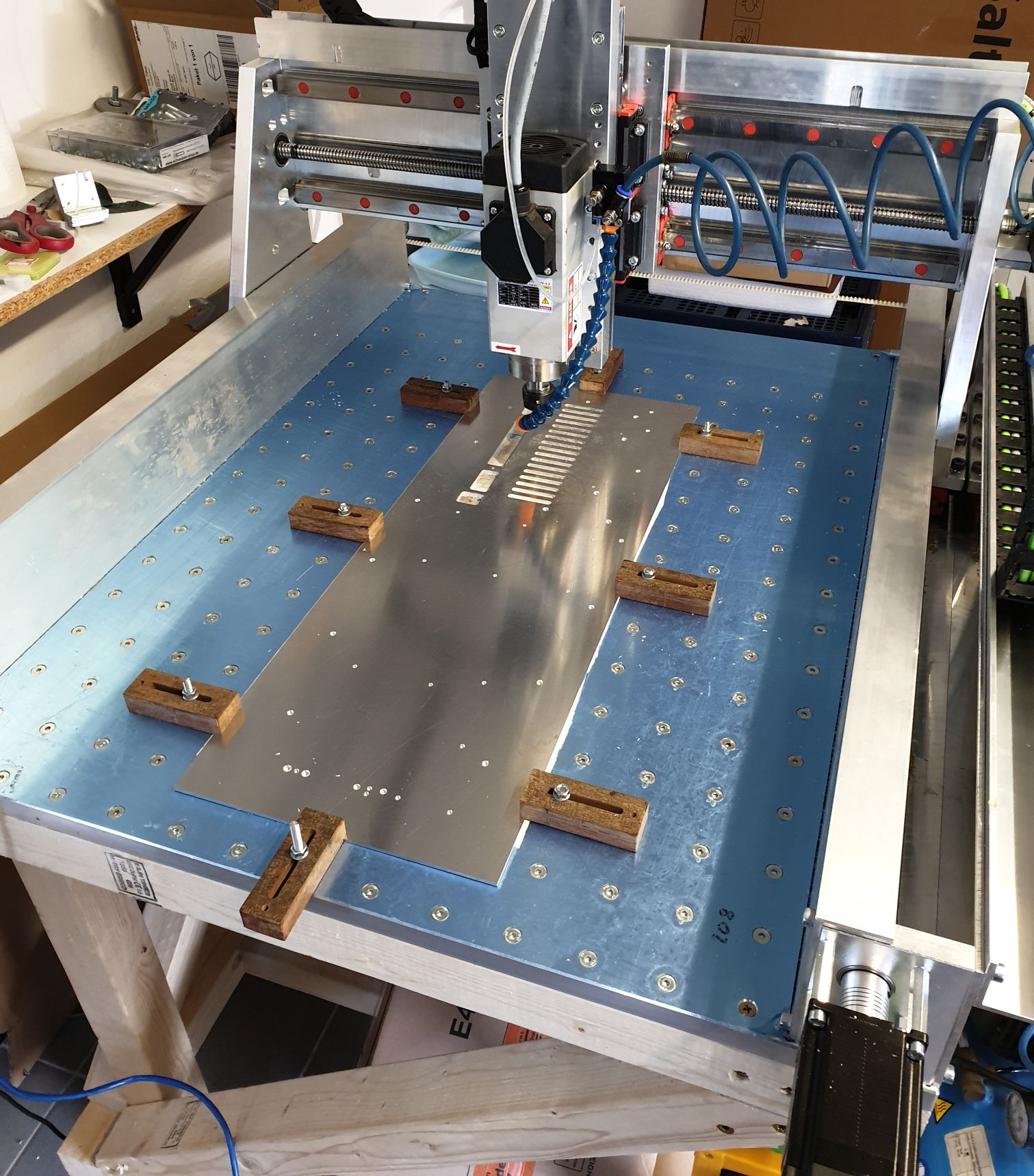

I do CNC machining myself in wood, plastic and alu on a self build CNC.

This project would be too complex to do without a CNC.

Any chance you have a build blog of the CNC. I'm currently looking into building one myself and yours look very well built

I have not done a blog myself but I bought the mechanical parts from a german guy who designed the machine. You can see how it is build here:

YouTube

I added controls, chinese servos and spindle and my wifes old laptop 🙂

I went for this one as it is really stiff and also very suited for milling aluminium.

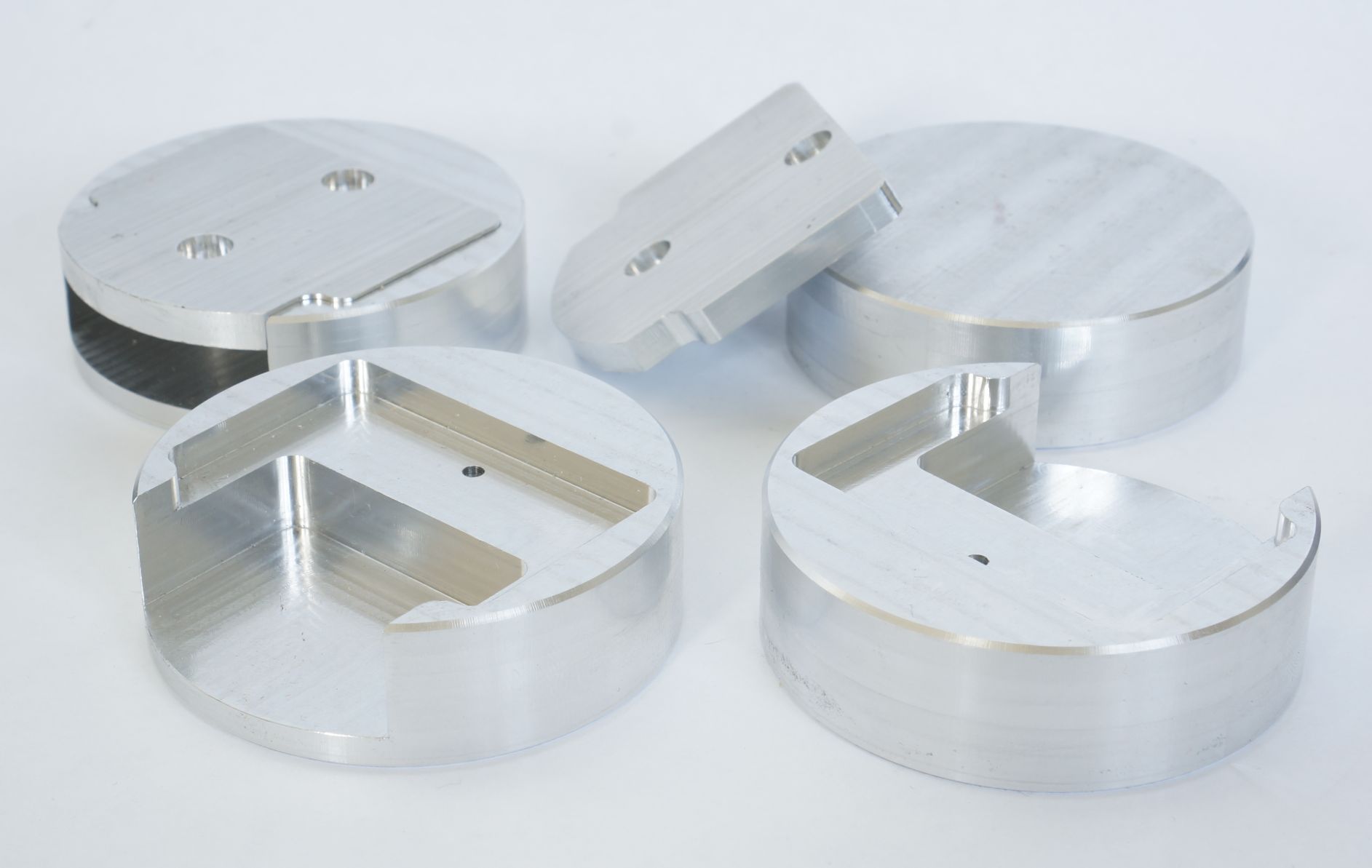

I have made some feet for the speakers on it this week.

YouTube

I added controls, chinese servos and spindle and my wifes old laptop 🙂

I went for this one as it is really stiff and also very suited for milling aluminium.

I have made some feet for the speakers on it this week.

Attachments

I have not done a blog myself but I bought the mechanical parts from a german guy who designed the machine. You can see how it is build here:

YouTube

I added controls, chinese servos and spindle and my wifes old laptop 🙂

I went for this one as it is really stiff and also very suited for milling aluminium.

I have made some feet for the speakers on it this week.

Looks great and thanks for the link

Hi everyone,

Today I had a bit more time to continue. I started with milling the mdf parts for the base structure. It all went well. I did a test fit and everythings fits nicely together. It even stands upright without glue or screws 🙂

Today I had a bit more time to continue. I started with milling the mdf parts for the base structure. It all went well. I did a test fit and everythings fits nicely together. It even stands upright without glue or screws 🙂

Attachments

Looking great! How did you machine the bevels, with contours and a ball end mill, or with a V-shaped bit?

Last edited:

Nice approach. I recently got interested in the 2x4HD as my active XO, couldn't find any info for 3 & 4 loudspeakers, but the fact that you are doing this should confirm that one indeed can use 1 input and split that among the 4 available outputs. So thanks.

Nice project by the way, subbing to follow the development. 🙂

Nice project by the way, subbing to follow the development. 🙂

Hi everyone,

I did the bevels with contouring in 0.5mm steps and a ball mill. Due to the tapered and slanted design none of the bevels are 45 deg. It does take some time though, more or less 15mins for the larger pieces.

Indeed once build there will be a lot of measuring and finetuning needed to get to the required results. I did some simulations in VituixCad but I need measurements on the real baffles before I can really fix things.

I did the bevels with contouring in 0.5mm steps and a ball mill. Due to the tapered and slanted design none of the bevels are 45 deg. It does take some time though, more or less 15mins for the larger pieces.

Indeed once build there will be a lot of measuring and finetuning needed to get to the required results. I did some simulations in VituixCad but I need measurements on the real baffles before I can really fix things.

Attachments

- Home

- Loudspeakers

- Multi-Way

- Active 4 way with MiniDSP and UCD