Hello Acoustat Folks,

At Roy E's suggestion I am posting a question to all Acoustat experts that have an understanding of acoustat maintenance and upkeep methodologies.

Below is a an excerpt from my post in the Facebook acoustat speakers group.

FYI

I am new to Acoustats, previously 30 yrs with Magnepans.

I acquired these 1+1's in august 2014, they sounded a bit flat but good otherwise at the time of acquisition, however, I didn't run them hard at the audition. The socks (beige) were filthy almost dark grey. I pulled them off and ran them through the wash three times and still filthy. So I bought some polyester chiffon printed fabric and made new socks.

While that was happening I sent the interfaces out to Roy in FLA for service and all upgrades + the AIR MOD. The interfaces came back, I installed and let them charge up for a day or so and I can say they sound amazing!

However there is an issue with arcing and I surmise it is due the the filthy condition of the speakers when I got them. While Roy was servicing the electronics as I said I made the new socks. I also inspected the internals, blew them out with compressed air and vac'd them too - gently.

At moderate volumes the panels mostly the right speaker will have a static discharge sizzle like sound. I contacted Roy about this who suggests naphtha to clean the panels, however that he is more of an electronics guy and not a panel guy. So my Facebook query is below with some interesting findings.

Please read and advise on means of remediation.

Facebook Acoustat Folks:

Can panel diaphragms become stretched (over time) beyond spec tolerances affecting performance, i.e. random static discharges at moderate volume bass notes? Panels have been gently blown out and vacuumed, still experiencing static type pops as noted above. Please advise. Thanks.

Rt Mack

Tell me what you are using for a power amp, ie are you clipping the amp? Pull the socks off, darken the room, play music, watch for sparks, inspect that area for suspicious artifact and or puncture.

October 30 at 6:27am · Like

Spieg Spiegs Bryston 3B fresh back from Bryston service (overhaul) in VT.

Amp is not clipping IMHO.

I do like the lights out study. Will do and advise. Model 1+1's, interfaces just back from Roy in FLA, they sound fabulous, the static discharge issue is a minor irritant.

Spieg Spiegs Rt Mack,

yes, the sock are off. Roy E. suggests 100% naphtha. I have some spray cans on order. If all fails, do folks really do the hair dryer route? Sounds sketchy...no pun intended.

Rt Mack

Petroleum distillate application would be a last resort for me....

Spieg Spiegs

I did the lights out test with some dynamic fusion-esque jazz at moderate volume.

Wow what a light show. Most interesting, flashes like sheet lightning in the distance and even more wild was the bundle of wires that comes from the upper panel diagonally to the lower panel, and down the left frame to the interface lit up like neon tubing. Only random static that you could hear, however, most bass hits lit up the wires like crazy. They still sound amazing though...

Thoughts? Recommendations to remediate?

Rt Mack

I can't remember how the wires are mounted (been awhile since my socks were off). But can you at least temporarily suspended them away from the panels? Re-observe them... Report back. [Hmm, now you got me pondering pulling my socks, maybe replacing the wires; 'wondering if ozone has attacked the insulation and broken it down??] First though, let's clean your wires with naphtha- but keep it off the panels as best you can. Try not to breath the fumes!!! Maybe even move them outside for cleaning. Also post this problem over on the Martin Logan FB forum as well. And also, just do a Google search on: Acoustat. there are several forums that are active on them. Keep me posted. Thanks and good luck. - Rt

Spieg Spiegs

Rt Mack thanks for your note. I will address your recommendations accordingly. When I have the naphtha, I will dismantle the panels from the interfaces and likely remove the felts too, air and vac again, then do the naphtha treatment outside and not in the house, heeding the directions. The bundles of wires are well away from the stators. I surmise that they are lighting up due to the static releases discharging to ground through the interfaces. I don't think relocating wires will have a remediation affect. I think the wires have micro carbon buildup, as the original beige socks were filthy almost dark gray when I acquired them in Aug. I also believe the diaphragms may be out of spec. (too flexy), contributing to the condition. I will post to the other planar groups, good idea.

Sort of a bummer as I just finished making the new poly chiffon socks. I fear with the static and socks on, a flash fire. I have to look into the combustibility of this material.

Rt Mack

Just suggesting relocating wires temporarily.... to insure that they are not the cause of discharges...

Spieg Spiegs

Hmm...both speakers are lighting up at the stock installed wiring over their full length. Do you think if I unhook the hold downs and pull the wiring bundle to the outside left frame the issue may terminate?

Yesterday at 10:49am · Like

Rt Mack I would give it a try, yes...

Spieg Spiegs I will advise.

At Roy E's suggestion I am posting a question to all Acoustat experts that have an understanding of acoustat maintenance and upkeep methodologies.

Below is a an excerpt from my post in the Facebook acoustat speakers group.

FYI

I am new to Acoustats, previously 30 yrs with Magnepans.

I acquired these 1+1's in august 2014, they sounded a bit flat but good otherwise at the time of acquisition, however, I didn't run them hard at the audition. The socks (beige) were filthy almost dark grey. I pulled them off and ran them through the wash three times and still filthy. So I bought some polyester chiffon printed fabric and made new socks.

While that was happening I sent the interfaces out to Roy in FLA for service and all upgrades + the AIR MOD. The interfaces came back, I installed and let them charge up for a day or so and I can say they sound amazing!

However there is an issue with arcing and I surmise it is due the the filthy condition of the speakers when I got them. While Roy was servicing the electronics as I said I made the new socks. I also inspected the internals, blew them out with compressed air and vac'd them too - gently.

At moderate volumes the panels mostly the right speaker will have a static discharge sizzle like sound. I contacted Roy about this who suggests naphtha to clean the panels, however that he is more of an electronics guy and not a panel guy. So my Facebook query is below with some interesting findings.

Please read and advise on means of remediation.

Facebook Acoustat Folks:

Can panel diaphragms become stretched (over time) beyond spec tolerances affecting performance, i.e. random static discharges at moderate volume bass notes? Panels have been gently blown out and vacuumed, still experiencing static type pops as noted above. Please advise. Thanks.

Rt Mack

Tell me what you are using for a power amp, ie are you clipping the amp? Pull the socks off, darken the room, play music, watch for sparks, inspect that area for suspicious artifact and or puncture.

October 30 at 6:27am · Like

Spieg Spiegs Bryston 3B fresh back from Bryston service (overhaul) in VT.

Amp is not clipping IMHO.

I do like the lights out study. Will do and advise. Model 1+1's, interfaces just back from Roy in FLA, they sound fabulous, the static discharge issue is a minor irritant.

Spieg Spiegs Rt Mack,

yes, the sock are off. Roy E. suggests 100% naphtha. I have some spray cans on order. If all fails, do folks really do the hair dryer route? Sounds sketchy...no pun intended.

Rt Mack

Petroleum distillate application would be a last resort for me....

Spieg Spiegs

I did the lights out test with some dynamic fusion-esque jazz at moderate volume.

Wow what a light show. Most interesting, flashes like sheet lightning in the distance and even more wild was the bundle of wires that comes from the upper panel diagonally to the lower panel, and down the left frame to the interface lit up like neon tubing. Only random static that you could hear, however, most bass hits lit up the wires like crazy. They still sound amazing though...

Thoughts? Recommendations to remediate?

Rt Mack

I can't remember how the wires are mounted (been awhile since my socks were off). But can you at least temporarily suspended them away from the panels? Re-observe them... Report back. [Hmm, now you got me pondering pulling my socks, maybe replacing the wires; 'wondering if ozone has attacked the insulation and broken it down??] First though, let's clean your wires with naphtha- but keep it off the panels as best you can. Try not to breath the fumes!!! Maybe even move them outside for cleaning. Also post this problem over on the Martin Logan FB forum as well. And also, just do a Google search on: Acoustat. there are several forums that are active on them. Keep me posted. Thanks and good luck. - Rt

Spieg Spiegs

Rt Mack thanks for your note. I will address your recommendations accordingly. When I have the naphtha, I will dismantle the panels from the interfaces and likely remove the felts too, air and vac again, then do the naphtha treatment outside and not in the house, heeding the directions. The bundles of wires are well away from the stators. I surmise that they are lighting up due to the static releases discharging to ground through the interfaces. I don't think relocating wires will have a remediation affect. I think the wires have micro carbon buildup, as the original beige socks were filthy almost dark gray when I acquired them in Aug. I also believe the diaphragms may be out of spec. (too flexy), contributing to the condition. I will post to the other planar groups, good idea.

Sort of a bummer as I just finished making the new poly chiffon socks. I fear with the static and socks on, a flash fire. I have to look into the combustibility of this material.

Rt Mack

Just suggesting relocating wires temporarily.... to insure that they are not the cause of discharges...

Spieg Spiegs

Hmm...both speakers are lighting up at the stock installed wiring over their full length. Do you think if I unhook the hold downs and pull the wiring bundle to the outside left frame the issue may terminate?

Yesterday at 10:49am · Like

Rt Mack I would give it a try, yes...

Spieg Spiegs I will advise.

This sounds like corona discharge from over-driving. Check the sensitivity of your panels. If the efficiency has dropped you will be driving them harder than normal and blue corona will be seen (and heard). Are the panels quiet with no music?

Hello Mike,

The panels are quiet when the system is off with the interfaces plugged in. Note however, the left panel has a very very faint random ticking noise, you really have to have your ear on the panel to hear it. The right speaker is quiet. Today when I tap on the grid (the socks are off) the panels are quiet. It's been cold the last few days in NH, the heat has been on and the RH is 50% in the room. Last week we had big rains in the area and RH was at 64% or so and that is when I noticed the static in some music and then with the system off a tap on the right channel grids yielded static pops central to the panel at eye level and just above by a bout 18". The left speaker would snap a bit here and there when tapped, but not as regularly. Regardless if I play material at moderate levels (loud but not clipping on the amp) in the dark you see the light show on bass hits etc!

So over driving the speakers I don't think so? How does one test sensitivity and what is the correct spec. What am I looking for? Note that Roy just overhauled the interfaces, all mods + the air mod. The lightning show last test was in air mode. I did another test on normal mode just now, similar results same music material. The amp (Bryston 3B is 200w at 4ohms or so) The volume was up yet red clipping lights not illuminating. I did notice random sparking close to the bottom of the top panel where the wires link to the bottom panel. After the first test a couple of days ago I did notice there was significant carbon like buildup on the wiring. So I will discharge the system tonight and tomorrow I'll disconnect the interfaces and clean all the wiring I can get to. I did notice thin soot lines on the front faces of the stator wires, that would entail swabbing each individual cell or use the spray Tronic Kleen that came today (with unknown contents although naphtha is noted on the can) Roy said use only 100% naphtha so I am apprehensive about that stuff, I don't want to kill my speakers when they are sounding so nice.

Your kind thoughts and feedback would be appreciated.

The panels are quiet when the system is off with the interfaces plugged in. Note however, the left panel has a very very faint random ticking noise, you really have to have your ear on the panel to hear it. The right speaker is quiet. Today when I tap on the grid (the socks are off) the panels are quiet. It's been cold the last few days in NH, the heat has been on and the RH is 50% in the room. Last week we had big rains in the area and RH was at 64% or so and that is when I noticed the static in some music and then with the system off a tap on the right channel grids yielded static pops central to the panel at eye level and just above by a bout 18". The left speaker would snap a bit here and there when tapped, but not as regularly. Regardless if I play material at moderate levels (loud but not clipping on the amp) in the dark you see the light show on bass hits etc!

So over driving the speakers I don't think so? How does one test sensitivity and what is the correct spec. What am I looking for? Note that Roy just overhauled the interfaces, all mods + the air mod. The lightning show last test was in air mode. I did another test on normal mode just now, similar results same music material. The amp (Bryston 3B is 200w at 4ohms or so) The volume was up yet red clipping lights not illuminating. I did notice random sparking close to the bottom of the top panel where the wires link to the bottom panel. After the first test a couple of days ago I did notice there was significant carbon like buildup on the wiring. So I will discharge the system tonight and tomorrow I'll disconnect the interfaces and clean all the wiring I can get to. I did notice thin soot lines on the front faces of the stator wires, that would entail swabbing each individual cell or use the spray Tronic Kleen that came today (with unknown contents although naphtha is noted on the can) Roy said use only 100% naphtha so I am apprehensive about that stuff, I don't want to kill my speakers when they are sounding so nice.

Your kind thoughts and feedback would be appreciated.

One more note: I am wondering if the diaphragms are stretched out of spec, along with the soot on the wiring, contributing to the concern. They are 30 years old or so...

Thanks.

Thanks.

Naptha? Dunno about naptha. Certainly outside and with a respirator.

But on the wires that you can grab, sure, fine.

Soak the panels with naptha? I'd be very careful about that.

The coating on the acoustats is very very rugged. Not sure how they did it exactly. I have personally washed them in the bathtub. Dip on edge only, don't want the water pushing on the diaphragm much.

If you have a lot of atmospheric goo, or worse good plus tobacco, they need cleaning. IF the socks were too dirty to come clean in the washing machine with bleach, then a lot of dirt is on the cells.

One thing is for sure, the side that is NOT coated can take much stronger cleaners, no problem! No matter what they need to be clear of soaps or detergents when ur done. And dead dry before turning them back on.

At 64% RH you could expect to get some "tizzzzing" and pops.

Not likely that there is a prob with diaphragm stretch causing the problem.

The dark room is a good way to see what is up and where the problem(s) are.

Some panels have the wires pull free from the glue that holds them on the stators, this seems to happen mostly on the ends. If that is where ur getting most of the arcing or tizz, you will need to inspect very carefully. The problem can be repaired.

If you are patient here, there are other very knowledgeable Acoustat people who will show up to hep too. They may or may not have the same opinions I do.

But on the wires that you can grab, sure, fine.

Soak the panels with naptha? I'd be very careful about that.

The coating on the acoustats is very very rugged. Not sure how they did it exactly. I have personally washed them in the bathtub. Dip on edge only, don't want the water pushing on the diaphragm much.

If you have a lot of atmospheric goo, or worse good plus tobacco, they need cleaning. IF the socks were too dirty to come clean in the washing machine with bleach, then a lot of dirt is on the cells.

One thing is for sure, the side that is NOT coated can take much stronger cleaners, no problem! No matter what they need to be clear of soaps or detergents when ur done. And dead dry before turning them back on.

At 64% RH you could expect to get some "tizzzzing" and pops.

Not likely that there is a prob with diaphragm stretch causing the problem.

The dark room is a good way to see what is up and where the problem(s) are.

Some panels have the wires pull free from the glue that holds them on the stators, this seems to happen mostly on the ends. If that is where ur getting most of the arcing or tizz, you will need to inspect very carefully. The problem can be repaired.

If you are patient here, there are other very knowledgeable Acoustat people who will show up to hep too. They may or may not have the same opinions I do.

Hi Spiegs,

Forum contributor bolserst has investigated corona issues with panels and I recall him discussing the Acoustat 1+1. He says the Acoustat 1+1 will generate corona on the stator when driven above approximately 38vrms. Your Bryston amp might have enough headroom to do this. Check the the tap on the MK interface should be set for 2 panels; I recall there is a setting for one panel and that would provide a higher step up ratio. To test efficiency, you need to drive one speaker with 2.83vrms and measure the SPL at 1m. Most modern portable multimeters do a good job measuring audio vrms and could be used to set the drive. Then use a SPL meter (like one from Radio Shack). I'm not sure about the efficiency for the 1+1 but it should be at least 80dB..perhaps a few dB higher.

Forum contributor bolserst has investigated corona issues with panels and I recall him discussing the Acoustat 1+1. He says the Acoustat 1+1 will generate corona on the stator when driven above approximately 38vrms. Your Bryston amp might have enough headroom to do this. Check the the tap on the MK interface should be set for 2 panels; I recall there is a setting for one panel and that would provide a higher step up ratio. To test efficiency, you need to drive one speaker with 2.83vrms and measure the SPL at 1m. Most modern portable multimeters do a good job measuring audio vrms and could be used to set the drive. Then use a SPL meter (like one from Radio Shack). I'm not sure about the efficiency for the 1+1 but it should be at least 80dB..perhaps a few dB higher.

Like Roy Esposito, I am a former Acoustat employee, although we worked there at different times.

I have NEVER heard of using Naptha for cleaning the panels, and I would strongly suggest AGAINST its use. Maybe it's okay, I don't know, but I wouldn't want to take the chance in using a strong solvent, as it may cause long-term degradation of the plastics. Jim Strickland (designer of the Acoustat speaker) recommended first to avoid washing the panels except as a last resort, and secondly using a mild soap like Woolite if you must.

The 1+1, being Acoustat's smallest-area full-range speaker, has always been the most problematic when it comes to arcing on large bass notes. This is because the speaker is very inefficient (requiring high drive levels), and the interface is set for maximum bass boost. This puts the maximum drive on the panels for large bass notes, easily reaching the panels' dynamic limit.

As you have observed, humidity is a factor, with higher levels possible under dry conditions. The random 'ticking' noise you hear is probably caused by a speck of dust caught in the gap, which allows a periodic, localized discharge. Completely discharge the speaker, and repeat the compressed air/vacuum procedure (several times if necessary).

Your Mylar diaphragm may have lost some tension. This will only make the problem worse. With the speaker discharged, use an industrial heatgun, positioned about 6" away from the panel, and constantly moving, to slowly heat the Mylar. Moderation is the key. You may need to repeat this process several times.

Check the condition of the felt blocks on the rear of the panels, as these damp the panel's motion. Loose or missing felt blocks will also contribute to the problem. These can be reattached with a contact glue.

There is a bass-boost tap inside the interface, which should be set to RED (maximum) for the 1+1. Other taps will give less bass boost, which will help with the arcing problem, but may make the speakers too bass-shy for your taste. Consider using a subwoofer crossed-over with a steep slope at 80-100 Hz.

So, you have plenty of things to check before you should consider washing the speaker.

I'm also going to guess that these 1+1's were built before Acoustat changed to a higher-resistivity conductive coating. This greatly improved the power handling capability of all the speakers, but made the most difference in the 1+1. Panels with the original coating can be identified with a solid red or white w/red stripe bias wire. The improved panels have a yellow w/red stripe bias wire. I mention this just for your information, as there's nothing you can do to upgrade the coating.

In my opinion, the 1+1 was always a compromise product, and is not suitable for people who like high sound levels. Its imaging characteristics are excellent, but it must be used within its dynamic limit. So even if you address all of the issues mentioned above, you will have to accept (or reject if necessary) the speaker's limited dynamic capacity.

And...I didn't know there is an Acoustat FB page! I'll have to check it out, as my aim is to help Acoustat owners!

I have NEVER heard of using Naptha for cleaning the panels, and I would strongly suggest AGAINST its use. Maybe it's okay, I don't know, but I wouldn't want to take the chance in using a strong solvent, as it may cause long-term degradation of the plastics. Jim Strickland (designer of the Acoustat speaker) recommended first to avoid washing the panels except as a last resort, and secondly using a mild soap like Woolite if you must.

The 1+1, being Acoustat's smallest-area full-range speaker, has always been the most problematic when it comes to arcing on large bass notes. This is because the speaker is very inefficient (requiring high drive levels), and the interface is set for maximum bass boost. This puts the maximum drive on the panels for large bass notes, easily reaching the panels' dynamic limit.

As you have observed, humidity is a factor, with higher levels possible under dry conditions. The random 'ticking' noise you hear is probably caused by a speck of dust caught in the gap, which allows a periodic, localized discharge. Completely discharge the speaker, and repeat the compressed air/vacuum procedure (several times if necessary).

Your Mylar diaphragm may have lost some tension. This will only make the problem worse. With the speaker discharged, use an industrial heatgun, positioned about 6" away from the panel, and constantly moving, to slowly heat the Mylar. Moderation is the key. You may need to repeat this process several times.

Check the condition of the felt blocks on the rear of the panels, as these damp the panel's motion. Loose or missing felt blocks will also contribute to the problem. These can be reattached with a contact glue.

There is a bass-boost tap inside the interface, which should be set to RED (maximum) for the 1+1. Other taps will give less bass boost, which will help with the arcing problem, but may make the speakers too bass-shy for your taste. Consider using a subwoofer crossed-over with a steep slope at 80-100 Hz.

So, you have plenty of things to check before you should consider washing the speaker.

I'm also going to guess that these 1+1's were built before Acoustat changed to a higher-resistivity conductive coating. This greatly improved the power handling capability of all the speakers, but made the most difference in the 1+1. Panels with the original coating can be identified with a solid red or white w/red stripe bias wire. The improved panels have a yellow w/red stripe bias wire. I mention this just for your information, as there's nothing you can do to upgrade the coating.

In my opinion, the 1+1 was always a compromise product, and is not suitable for people who like high sound levels. Its imaging characteristics are excellent, but it must be used within its dynamic limit. So even if you address all of the issues mentioned above, you will have to accept (or reject if necessary) the speaker's limited dynamic capacity.

And...I didn't know there is an Acoustat FB page! I'll have to check it out, as my aim is to help Acoustat owners!

Hello Andy,

I have read most all of your responses to others querying panel popping and buzzing issues.

So it is a real a treat to receive your letter of expertise.

I have drilled Roy with so many questions since coming over from the dark side (Magnepans). I really knew nothing about ESL's (loved Acoustats from an audition in the 80's) so Roy was instrumental in educating me about Acoustats and what to look/listen for when auditioning Acoustats for sale.

Ended up doing a day drip to NJ from NH to hear and buy these units. The guy was running them with a Hafler 200 which didn't sound too great but otherwise seemed fine, one channel sounded a bit weak but not running on my Bryston when installed back in NH. As I mentioned above in the thread the socks were really filthy. I now see the stator wires that were lighting up like neon tubing in my dark room test are really filthy too. So, I would like to clean them thinking its good to remove all foreign debris. I was pondering Windex sprayed on a paper towel pad and wipe down each accessible wire accordingly. I was also thinking of using isopropyl alcohol instead of Windex. Your thoughts would be appreciated here. I appreciate your feedback on the naphtha, that stuff scares me. I have a high heat air blower and a little scared of using that too frankly. The 1+1's sound so amazing after Roy's handy work (air mode puts you on stage), it would be so painful to damage these babies. I was wondering if adding another Bryston 3B to the system would be helpful, monoblock layout I believe as opposed to biamping as with the old the Magnepans. I used to have a Quatra something amp it was so long ago, it died and I then went with the Bryston solo and took off the Maggie crossover box. There are a bunch of Bryston 3B's out there in eBay land...yea or nay on more power?

Thank you (and all responders) so much for your attention!

I have read most all of your responses to others querying panel popping and buzzing issues.

So it is a real a treat to receive your letter of expertise.

I have drilled Roy with so many questions since coming over from the dark side (Magnepans). I really knew nothing about ESL's (loved Acoustats from an audition in the 80's) so Roy was instrumental in educating me about Acoustats and what to look/listen for when auditioning Acoustats for sale.

Ended up doing a day drip to NJ from NH to hear and buy these units. The guy was running them with a Hafler 200 which didn't sound too great but otherwise seemed fine, one channel sounded a bit weak but not running on my Bryston when installed back in NH. As I mentioned above in the thread the socks were really filthy. I now see the stator wires that were lighting up like neon tubing in my dark room test are really filthy too. So, I would like to clean them thinking its good to remove all foreign debris. I was pondering Windex sprayed on a paper towel pad and wipe down each accessible wire accordingly. I was also thinking of using isopropyl alcohol instead of Windex. Your thoughts would be appreciated here. I appreciate your feedback on the naphtha, that stuff scares me. I have a high heat air blower and a little scared of using that too frankly. The 1+1's sound so amazing after Roy's handy work (air mode puts you on stage), it would be so painful to damage these babies. I was wondering if adding another Bryston 3B to the system would be helpful, monoblock layout I believe as opposed to biamping as with the old the Magnepans. I used to have a Quatra something amp it was so long ago, it died and I then went with the Bryston solo and took off the Maggie crossover box. There are a bunch of Bryston 3B's out there in eBay land...yea or nay on more power?

Thank you (and all responders) so much for your attention!

Unless you are driving your current amplifier into clipping (and a previous post said you aren't) then adding MORE power will only make the situation worse. You are already providing as much as (or more than) the speaker will handle. Furthermore, I recommend against using bridged amplifiers on low impedance speakers such as the Acoustat. Each half of the bridged amp 'sees' only half the load impedance. Therefore, that 4-ohm minimum impedance now looks like 2-ohms. Most amps won't tolerate that very well, or at the very least won't deliver any more power.

Windex would be a better choice for cleaning the soot off the wires. Denatured or isopropyl alcohol would probably also be okay, but I feel less sure about that. Do not get any alcohol on the conductive coating. For that matter, I would suggest you avoid any cleaning agents on the diaphragm.

Windex would be a better choice for cleaning the soot off the wires. Denatured or isopropyl alcohol would probably also be okay, but I feel less sure about that. Do not get any alcohol on the conductive coating. For that matter, I would suggest you avoid any cleaning agents on the diaphragm.

Ordinary Windex is alcohol + water + blue dye.

I've cleaned quite many Acoustat cells in the bathtub with hot water and mild detergent. Ymmv.

I'd go for a different amp than a Bryston. I think that they have a characteristic sound that I do not enjoy.

A scope will tell you if you are clipping the amp on peaks. You might want to pick up a used working scope, Tektronix and other good brands are pretty cheap these days on epay, and there is a surplus outlet near Manchester that has quite a decent selection.

PM me if ur interested in a pair of IIs in Ct., not terribly expensive.

You could make IIs that way... I like IIIs.

If I recall the nominal impedance from the graph/curve that Acoustat put out was closer to 6 ohms.

I'm scratching my head a bit, but the 4 ohm load on a bridged amp, afaik is still 4 ohms. What happens is that the voltage across the load is doubled, therefore the power is 4x and in most cases the amp can not deliver enough current.

_-_-bear

I've cleaned quite many Acoustat cells in the bathtub with hot water and mild detergent. Ymmv.

I'd go for a different amp than a Bryston. I think that they have a characteristic sound that I do not enjoy.

A scope will tell you if you are clipping the amp on peaks. You might want to pick up a used working scope, Tektronix and other good brands are pretty cheap these days on epay, and there is a surplus outlet near Manchester that has quite a decent selection.

PM me if ur interested in a pair of IIs in Ct., not terribly expensive.

You could make IIs that way... I like IIIs.

If I recall the nominal impedance from the graph/curve that Acoustat put out was closer to 6 ohms.

I'm scratching my head a bit, but the 4 ohm load on a bridged amp, afaik is still 4 ohms. What happens is that the voltage across the load is doubled, therefore the power is 4x and in most cases the amp can not deliver enough current.

_-_-bear

Highly recommendedA scope will tell you if you are clipping the amp on peaks.

It is very educational to see how often and how badly we run our amps into clipping during "normal" listening.

I'm scratching my head a bit, but the 4 ohm load on a bridged amp, afaik is still 4 ohms. What happens is that the voltage across the load is doubled, therefore the power is 4x and in most cases the amp can not deliver enough current.

I think what he is saying is the effective load on each amplifier channel is half of the load applied to the bridged configured amplifier.

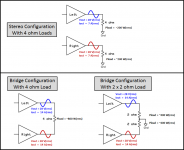

Attached is a figure that compares voltage, current, and power output for stereo and bridged configurations.

As you stated, power increases 4x when going from stereo to bridged and current increases 2x.

Ohms Law for AC circuits tells you that the effect load on each amplifier channel has been halved.

With the 4 ohm load driven by equal and opposite voltages at its ends there is a virtual ground at the midpoint of the load.

You can think of it as replacing the 4 ohm load with 2 x 2ohm loads with the center point grounded.

Attachments

In response to Andy's note on bridging.

I was wondering if the Bryston was possibly struggling contributing to the static discharges. It sounds like more power is not the answer here. True?

Getting to the next task at hand: I have powered down the interfaces and will disengage and free up all of the wiring and do a thorough cleaning - soot removal. I noticed the stator grids - last couple of horizontal cells at top and bottoms are sooty as well, I will hit these cautiously with a q-tip with the least volatile cleaner. I will carefully run some hot air on the rear mylar sides as well, maybe the diaphragms will tighten up a bit.

More later...and thanks to all.

I was wondering if the Bryston was possibly struggling contributing to the static discharges. It sounds like more power is not the answer here. True?

Getting to the next task at hand: I have powered down the interfaces and will disengage and free up all of the wiring and do a thorough cleaning - soot removal. I noticed the stator grids - last couple of horizontal cells at top and bottoms are sooty as well, I will hit these cautiously with a q-tip with the least volatile cleaner. I will carefully run some hot air on the rear mylar sides as well, maybe the diaphragms will tighten up a bit.

More later...and thanks to all.

Hi Spiegs, I have Bryston 6B mono blocks, which are a version of the paralled 3B, They run my 1 ohm Apogee Scintilla's effortless to 115db, YET they won't run my Acoustat 2+2s period, red lights come on and get HOT in seconds. I have alot of speakers here, they just don't like 4 or 8 ohm loads.

Hi Spiegs, I have Bryston 6B mono blocks, which are a version of the paralled 3B, They run my 1 ohm Apogee Scintilla's effortless to 115db, YET they won't run my Acoustat 2+2s period, red lights come on and get HOT in seconds. I have alot of speakers here, they just don't like 4 or 8 ohm loads.

It's not just a matter of the magnitude of the impedance (i.e. number of ohms), but also the reactance of the load presented to the amplifier.

I suspect ribbon speakers like the Apogee are mostly a pure resistance.

Therefore, they represent a fairly 'tame' load to the amplifier. The very low impedance isn't a problem for most amplifiers as long as you remain within the thermal limits.

Electrostatic loudspeakers like the Acoustat are highly reactive, with lots of inductance and capacitance, meaning that there are significant phase differences between voltage and current at some frequencies. This is what causes some amps to be unstable into these loads, or in some cases, merely drives the protection circuits crazy.

All of this means, of course, that an amplifier that is 'perfect' at driving one speaker with low-rated impedance may not be a great choice for driving a different speaker, even if the impedance rating is higher.

"Your Mylar diaphragm may have lost some tension. This will only make the problem worse. With the speaker discharged, use an industrial heatgun, positioned about 6" away from the panel, and constantly moving, to slowly heat the Mylar. Moderation is the key. You may need to repeat this process several times."

Hello Andy,

Regarding your note pasted in above: Please advise if one should apply heat to the front, rear or both faces of the Mylar?

Thanks.

Hello Andy,

Regarding your note pasted in above: Please advise if one should apply heat to the front, rear or both faces of the Mylar?

Thanks.

"Your Mylar diaphragm may have lost some tension. This will only make the problem worse. With the speaker discharged, use an industrial heatgun, positioned about 6" away from the panel, and constantly moving, to slowly heat the Mylar. Moderation is the key. You may need to repeat this process several times."

Hello Andy,

Regarding your note pasted in above: Please advise if one should apply heat to the front, rear or both faces of the Mylar?

Thanks.

It doesn't matter, as the material is so thin that heat on one side is as good as heat the other side. However, as a matter of convenience, I would apply heat from the front of the panel. The felt blocks on the rear side will interfere with the even application of heat.

Update: Corona Issues_1+1's

I powered down the panels and disassembled from the interfaces.

Blew them out again with compressed air, then vac'd.

After which I painstakingly cleaned all the exposed wiring with isopropyl alcohol and absorptive paper towels. And very carefully swabbed each stator cell's wires with Q-tips (what a hassle), mostly the center wire had a black buildup, swabbed even the clean looking ones, dirt there too actually. Then at Andy's direction, carefully applied the heat gun (in concentric passes) over each panel front at 8" or so constantly moving at a slow rate but not too slow to melt any internals. Let everything cool down and then reassembled and charged up the panels for about 36 hours. Did another corona test in the dark with the same music material - moderate volume - definitely no Bryston clipping.

First off, they sound amazing maybe even better post heat gun, it's hard to tell. In the dark very little corona on the left speaker with subtle wire glow here and there. The right speaker had more pronounced corona and again at similar random locations as before and along the wiring, yet this test yielded less corona and wiring glow overall than before the cleaning and heat gun work.

I don't know if it is going to get any better than that.

I didn't hear any pops in particular when doing the test.

I am very happy with the sound quality (venerable Masters Roy, Andy et al diyaudio). My thoughts are to install the new polyester chiffon (super shear) socks at this point. Before I do so, should I be concerned with the corona output as a fire hazard with such a fine fabric?

Please advise and many thanks in advance.

Spiegs

I powered down the panels and disassembled from the interfaces.

Blew them out again with compressed air, then vac'd.

After which I painstakingly cleaned all the exposed wiring with isopropyl alcohol and absorptive paper towels. And very carefully swabbed each stator cell's wires with Q-tips (what a hassle), mostly the center wire had a black buildup, swabbed even the clean looking ones, dirt there too actually. Then at Andy's direction, carefully applied the heat gun (in concentric passes) over each panel front at 8" or so constantly moving at a slow rate but not too slow to melt any internals. Let everything cool down and then reassembled and charged up the panels for about 36 hours. Did another corona test in the dark with the same music material - moderate volume - definitely no Bryston clipping.

First off, they sound amazing maybe even better post heat gun, it's hard to tell. In the dark very little corona on the left speaker with subtle wire glow here and there. The right speaker had more pronounced corona and again at similar random locations as before and along the wiring, yet this test yielded less corona and wiring glow overall than before the cleaning and heat gun work.

I don't know if it is going to get any better than that.

I didn't hear any pops in particular when doing the test.

I am very happy with the sound quality (venerable Masters Roy, Andy et al diyaudio). My thoughts are to install the new polyester chiffon (super shear) socks at this point. Before I do so, should I be concerned with the corona output as a fire hazard with such a fine fabric?

Please advise and many thanks in advance.

Spiegs

My suggestion to re-shrink the Mylar was aimed at eliminating the random 'tick' noises and especially the rattles on big bass notes. The tension on the diaphragm will have no bearing on the wires showing a corona under high drive conditions.

I would not be concerned about the corona causing a fire hazard unless the speaker is driven way beyond reasonable limits. However, I would avoid having the wires touching the fabric, so as to avoid the eventual accumulation of black soot on the cloth.

I would not be concerned about the corona causing a fire hazard unless the speaker is driven way beyond reasonable limits. However, I would avoid having the wires touching the fabric, so as to avoid the eventual accumulation of black soot on the cloth.

Hi Spiegs, I have Bryston 6B mono blocks, which are a version of the paralled 3B, They run my 1 ohm Apogee Scintilla's effortless to 115db, YET they won't run my Acoustat 2+2s period, red lights come on and get HOT in seconds. I have alot of speakers here, they just don't like 4 or 8 ohm loads.

Are Brystons OK with capacitive loads? I had a 7B that tripped the house breaker every time I turned it on...

I also had no issues with my scinnies with most amps (not pushed tho), but most all my amps had a difficult time with my Acoustat Model 3...no issues yet with my 2+2... If bias is low, they will be more difficult to drive.

I played around with bias voltage on my 2+2 and definitely see an improvement with higher bias voltage. Check your bias voltage at the red wire connection - using a standard 10 meg ohm meter, should be around 75vdc (5kv), I added one more diode / cap multiplier "Rung" (adds approx 1kv) and sounds better and amp has easier time...

I also did the Spectra 11 "Ultrasonic Fix" from Andy and was able to raise bias pin to 85v and it definitely was easier to drive and sounded better - I could go all the way to 100v without panel buzzing, but that may lead the panel to be "louder" than the woofers.....they were "voiced" at 5kv...

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Acoustat 1+1 New to Acoustat have panel concerns -