I've seen my homes power fluctuate down to 118v and up to 125v. I want to use AC heaters on 8BQ5, 6BQ5 or 10BQ5 with a lock key switch to select what voltage tube you are installing. (doing this because I own a lot of 8 and 10 volt BQ5's). I can experimentally come up with the right resistor(s) to switch, but its not regulated. What about AC regulation using LM1084? It would make voltage selection easy peasy.

But would the clipped waveform present noise or power loss issues to make it not worth even considering for AC heaters?

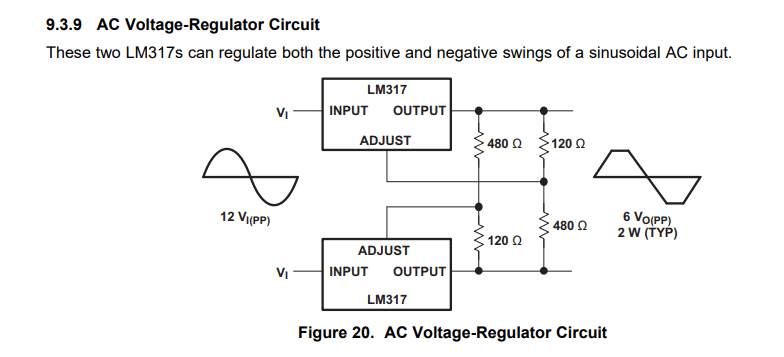

This application but using a beefier 5A regulator not a 317.

But would the clipped waveform present noise or power loss issues to make it not worth even considering for AC heaters?

This application but using a beefier 5A regulator not a 317.

I think you'll also need reverse protection diodes across each regulator - circuit may be intended for low levels only. Heater is insulated from cathode and it's a high level stage so noise won't be a problem. You'll need to experiment with resistor values since the RMS (heating) value is what's important and the trapezoidal waveform you'll have will not measure correctly with an average-responding DMM. You could also use a dual 1k pot and measure with an RMS meter when you change it. Regulators will need heatsinks; lotsa watts with 6BQ5s.

The most efficient way to do this is with a dropping resistor for 10BQ5 from 12V, diode for 8BQ5 (.707*12=8.5V), 6V winding for 6BQ5. For 8BQ5s, you'd split them between diodes of the opposite polarity to avoid DC in the transformer.

The most efficient way to do this is with a dropping resistor for 10BQ5 from 12V, diode for 8BQ5 (.707*12=8.5V), 6V winding for 6BQ5. For 8BQ5s, you'd split them between diodes of the opposite polarity to avoid DC in the transformer.

Last edited:

"The most efficient way to do this is with a dropping resistor for 10BQ5 from 12V, diode for 8BQ5 (.707*12=8.5V), 6V winding for 6BQ5. For 8BQ5s, you'd split them between diodes of the opposite polarity to avoid DC in the transformer."

That is pretty clever! I'd only need a single 12v CT transformer. In 10v mode it switches in a resistor (which happens to have the lowest current draw tube), in 8v mode it switches in the diodes and in 6v mode it simply parallels the secondary. Not regulated but it trades a whole bunch of other issues and doesnt introduce new issues like heatsinking, reliability, etc. I was kicking around using multiple transformers but this really saves space.

So for the diodes, you mean a diode in each leg of the 12v but opposing? Maybe TO220 diodes, lower voltage but higher current and have a heat tab.

I would keep it simple.

Resistor attenuated 60Hz is less of a noisemaker than any clipped waveform.

Or take the bull by the horns, rectify/filter filament voltage and feed tubes regulated DC , switch selectable.

Very clean and precise.

Resistor attenuated 60Hz is less of a noisemaker than any clipped waveform.

Or take the bull by the horns, rectify/filter filament voltage and feed tubes regulated DC , switch selectable.

Very clean and precise.

I would keep it simple.... rectify/filter filament voltage and feed tubes regulated DC , switch selectable. Very clean and precise.

In my case I want to use a variety of tubes with the same heater voltage but different current requirements. In this case DC will give me the voltage I need and I can use any tubes with that voltage. There are sometimes practical uses for DC heating. I use LM1084.

There's the option of switch mode supplies, and they are adjustable around a 2v range approx.

Feed one or two heaters with diode of one polarity, and one or two with opposite polarity. Net load is AC.That is pretty clever! I'd only need a single 12v CT transformer. In 10v mode it switches in a resistor (which happens to have the lowest current draw tube), in 8v mode it switches in the diodes and in 6v mode it simply parallels the secondary. Not regulated but it trades a whole bunch of other issues and doesnt introduce new issues like heatsinking, reliability, etc. I was kicking around using multiple transformers but this really saves space.

So for the diodes, you mean a diode in each leg of the 12v but opposing? Maybe TO220 diodes, lower voltage but higher current and have a heat tab.

I did consider regulated DC at first, but since it's power tubes thought it would be worth exploring how to get 3 different voltages AC as well. With a regulator it would just be a switch for three different adjustment resistors, super simple. A 10v flat pack transformer might meet the cutoff, if not it would have to be a 12v flatpack.

https://catalog.triadmagnetics.com/...nt-flat-pack-power-transformers-1/fp10-4800-1

https://catalog.triadmagnetics.com/...nt-flat-pack-power-transformers-1/fp12-3800-1

https://catalog.triadmagnetics.com/...nt-flat-pack-power-transformers-1/fp10-4800-1

https://catalog.triadmagnetics.com/...nt-flat-pack-power-transformers-1/fp12-3800-1

You'll need 12.6VAC to get anywhere near the transformer's rating before dropout. 4A transformer would be marginal - I'd expect 5A including ripple current.

Here's a dirt simple (and damned inefficient) method: 16V transformer, 13 Ohm resistor in series with each tube. 6BQ5 gets .75A, 8BQ5 gets .61A, 10BQ5 draws .44A. No switching, you could even mix them. 30W of heat, worst case, though maybe no worse than the linear regulator. These is power tubes, folks...

Tapped transformer or switching regulator is the only efficient way to do it.

Here's a dirt simple (and damned inefficient) method: 16V transformer, 13 Ohm resistor in series with each tube. 6BQ5 gets .75A, 8BQ5 gets .61A, 10BQ5 draws .44A. No switching, you could even mix them. 30W of heat, worst case, though maybe no worse than the linear regulator. These is power tubes, folks...

Tapped transformer or switching regulator is the only efficient way to do it.

Last edited:

You'll need 12.6VAC to get anywhere near the transformer's rating before dropout. 4A transformer would be marginal - I'd expect 5A including ripple current.

Here's a dirt simple (and damned inefficient) method: 16V transformer, 13 Ohm resistor in series with each tube. 6BQ5 gets .75A, 8BQ5 gets .61A, 10BQ5 draws .44A. No switching, you could even mix them. 30W of heat, worst case, though maybe no worse than the linear regulator. These is power tubes, folks...

Tapped transformer or switching regulator is the only efficient way to do it.

I thought of that one too after reading an old John Broskie article on plugging in 6 or 12v tubes any timee, just let ohms law do the work! But I was having a hard time doing the math to get all 3 voltages to work, maybe I was just trying to be too accurate. I kinda like the method though it is inefficient.

I am curious how this will work/sound in your system.

If you produce a waveform like the one shown an FFT will have a lot of high order harmonics. Depending on the quality of your line voltage input it may or may not be better.

I setup a test apparatus to test power tubes with different filament voltages. I rectified and filtered the output from a small commercial variac power supply. I put a meter on the output and adjusted the variac until I got the proper voltage on the tube. It was more than adequate for the intended purpose.

Steve

If you produce a waveform like the one shown an FFT will have a lot of high order harmonics. Depending on the quality of your line voltage input it may or may not be better.

I setup a test apparatus to test power tubes with different filament voltages. I rectified and filtered the output from a small commercial variac power supply. I put a meter on the output and adjusted the variac until I got the proper voltage on the tube. It was more than adequate for the intended purpose.

Steve

Here's a dirt simple (and damned inefficient) method: 16V transformer, 13 Ohm resistor in series with each tube. 6BQ5 gets .75A, 8BQ5 gets .61A, 10BQ5 draws .44A. No switching, you could even mix them. 30W of heat, worst case, though maybe no worse than the linear regulator. These is power tubes, folks...

I have in my stash a 200W 15V (adjustable +/- 5%) switcher rated 13.3 amps. Turned up it outputs 15.75v. If I wire a 12.5 ohm resistor to each socket, I might have the best of all worlds here:

1) Ability to plug in any voltage tube, no worries, 6, 8 or 10 BQ5

2) Ability to mix tube voltages

3) DC heaters, not that this would matter much with power tubes, but still another way to fight hum, no need to create a virtual CT, etc.

4) I get Regulation from my crazy power company fluctuating 118 to 125

5) The series resistors should keep the switcher from shutting down at start up, built in inrush

6) Slower start up of my filaments with series resistors prolonging their life, these are NOS 8, 10 BQ5s.

7) I don't have to contrive any voltage selection switches which would only confuse future owner, or have someone switch it to 10 with 6v tubes installed.

Whats not to like?

Sure the cost is the heat and power waste, oversizing the resistors will help the heat aspect, nothing can be done about the waste thats just the price for the list above.

FYI: It is not your power company that is solely responsible for the voltage fluctuations. OHM's law is probably the bigger factor. All line power feed systems have some resistance.

The power draw on the transformer and lines feeding your home and others will cause voltage drops as the demand changes. The closer you are to the power source the higher the voltage. In my house turning on the washer, dryer, oven etc. causes a voltage drop of several volts. When my neighbors are home there are a lot of fluctuations after 5pm. My line voltage varies from 117 to 122 during those times.

The voltage is most stable after midnight when most of people are sleeping (doing nothing).

Steve

The power draw on the transformer and lines feeding your home and others will cause voltage drops as the demand changes. The closer you are to the power source the higher the voltage. In my house turning on the washer, dryer, oven etc. causes a voltage drop of several volts. When my neighbors are home there are a lot of fluctuations after 5pm. My line voltage varies from 117 to 122 during those times.

The voltage is most stable after midnight when most of people are sleeping (doing nothing).

Steve

Here it has to do with overall demand, not at the house or neighborhood level, its the power company regulating intentionally. Its a slow transition. The house has 250 Amp service, I could flip on my 3HP table saw with the 2HP dust collector running too, while the AC is running and no lamps anywhere even flicker.

Or you could get an inexpensive toroid and wind some buck/boost windings on it as needed. It would be fairly efficient, and provide clean AC at the voltages you need.

The toroid idea is pretty slick! Just calculate the additional number of windings needed to drop the voltage to what you need and switch them in or out. You could take advantage of a dual input voltage unit to cut between 12.6 and 6.3! Just make sure a single primary can power the load.

Or you could get an inexpensive toroid and wind some buck/boost windings on it as needed. It would be fairly efficient, and provide clean AC at the voltages you need.

Yes thats a good option too, just get an unshielded torroid and add on the tapped winding. So so far I think this method and the dropping resistors are best. Winding some dedicated voltages is most efficient. But all things have a cost in either waste or features. With a torroid we can't mix tube voltages, we'd need a user switch to select what tubes are installed, less important its not regulated. But it does get me back to all the features I originally wanted, that is to use all of either 6, 8 or 10 v tubes, unmixed. The user switch can be destructive in the hands of a confused user, so this is where individual resistors and a supply well over 10 v is more stupid-proof. But resistors waste power. So the features list above is constantly changing based on the design. Listing what features and advantages you get or have to give up with each method adds clarity. Such a balancing act DIY is!

- Home

- Amplifiers

- Tubes / Valves

- AC Heaters, dropping resistor vs. regulator?