Wondering if anyone has any advice on this....

I need to cut 1/2" wide polycarbonate spacers for the grid part of my panels.

Any recommendations on how to cut it? So far, tin snips seems to be the "best" way but not ideal.

Tried, my tablesaw, a diamond blade wet saw and just scoring with razor and snapping it off..... none of that worked well 🙂

You can bandsaw cut it with a fine tooth metal blade. Or, if it's fairly thin (1/16" thick or less) you can cut thru it making multiple passes with a straight edge and box knife -- not just score it and break it but score it multiple times until you finally cut thru it.

I will try a higher tooth blade but I found when I try to feed it in it just broke/shattered the PC. It is only about .07" thick.

Hmmmm...I have cut up very narrow strips of similar thickness PC without issue....when I try to feed it in it just broke/shattered the PC. It is only about .07" thick.

It's possible the particular shape of the teeth on the blades made for cutting plastic made the difference, I'm not sure.

You might also try using a sheet of MDF on top of the PC to help stabilize, setting the blade height to only cut a few mm into the MDF.

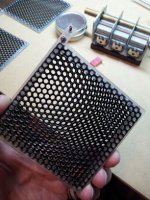

Attachments

Now that you mention it, I may have had my blade set way too high. The MDF backer is also a good suggestion.

Also note I am trying to cut 1/4" strips from a 1.5" wide strip versus a big sheet.

Also note I am trying to cut 1/4" strips from a 1.5" wide strip versus a big sheet.

Also note I am trying to cut 1/4" strips from a 1.5" wide strip versus a big sheet.[/QUOTE]

That sounds a little scary, even if you have a SawStop. You might try using a good double sided tape(such as scor-tape) to stick the 1.5" strips to a smooth faced MDF piece that is large enough to give you plenty of space between the blade and your fingers. Once the strips are cut, carefully peel the poly off the tape.

On my particular table saw, the gap between the tabletop insert opening and the saw blade is around 1/4", so there's a tendency for the blade to enjoy adding short thin ripped strips to the pile of sawdust underneath. You may have the same problem. One of these days I might try building a plywood insert with little to no gap to see if it helps with thin strips and lessens splintering when cutting sheet plastics. We'll see.

That sounds a little scary, even if you have a SawStop. You might try using a good double sided tape(such as scor-tape) to stick the 1.5" strips to a smooth faced MDF piece that is large enough to give you plenty of space between the blade and your fingers. Once the strips are cut, carefully peel the poly off the tape.

On my particular table saw, the gap between the tabletop insert opening and the saw blade is around 1/4", so there's a tendency for the blade to enjoy adding short thin ripped strips to the pile of sawdust underneath. You may have the same problem. One of these days I might try building a plywood insert with little to no gap to see if it helps with thin strips and lessens splintering when cutting sheet plastics. We'll see.

Thanks for the memory jog, this is exactly what I do....just forgot to mention it. I clamp a sheet of 3/8" MDF to the table with the fence set to the desired width. Then turn on the saw and raise the blade thru the MDF sheet just enough to cut the thickness of plastic I need....One of these days I might try building a plywood insert with little to no gap to see if it helps with thin strips and lessens splintering when cutting sheet plastics. We'll see.

Another thing that is useful is a small ~6" piece of MDF clamped to the fence over top of the blade leaving a gap between it and the lower MDF sheet just thicker than the plastic. That way the thin strips don't try and ride up the blade as they are pushed thru.

Thanks for the tip on clamping a block of wood to the fence over the top of the blade. Cutting my next plastic sheet will now be much easier and safer. Previously, I'd been raising the blade too high just so the the plastic wouldn't start 'riding up'.

Thanks for the tip on clamping a block of wood to the fence over the top of the blade. Cutting my next plastic sheet will now be much easier and safer. Previously, I'd been raising the blade too high just so the the plastic wouldn't start 'riding up'.

Yeah, I had the same issue.... I think the problem I had is when the blade is high it rides up the blade and then at some point gets "slammed" back down....then it breaks/shatters.

Whenever I get a little too "frisky" with my tablesaw, I think of this video and remind myself my fingers/hands are worth more 🙂

https://youtu.be/u7sRrC2Jpp4?t=153

Hi CharlieM,

I came across an older post of yours http://www.diyaudio.com/forums/planars-exotics/192303-curved-vs-flat-esl-panels.html back in 2011 when you considered curved versus flat panel ESLs. You succinctly described the performance of a flat panel thus: "a flat panel's sweet spot [is] very pronounced and only about as wide as the panel itself". At that time you were considering building a segmented ESL in order to gain a wider sweet spot. Now that you have done this, it would be very interesting to hear how you would describe the width of the wide dispersion mode in your ESL. How does it compare with the width of the panel?

I came across an older post of yours http://www.diyaudio.com/forums/planars-exotics/192303-curved-vs-flat-esl-panels.html back in 2011 when you considered curved versus flat panel ESLs. You succinctly described the performance of a flat panel thus: "a flat panel's sweet spot [is] very pronounced and only about as wide as the panel itself". At that time you were considering building a segmented ESL in order to gain a wider sweet spot. Now that you have done this, it would be very interesting to hear how you would describe the width of the wide dispersion mode in your ESL. How does it compare with the width of the panel?

You don't hear beams, you hear timbre. There are lots of ways of getting the timbre right without needing the construction challenges of making curved cells.

You start with room acoustics, reading Toole's book.

ESL beaming is always portrayed in what architects call "plan view". That's a pretty static way to think about it.

Ben

You start with room acoustics, reading Toole's book.

ESL beaming is always portrayed in what architects call "plan view". That's a pretty static way to think about it.

Ben

Hi CharlieM,

I came across an older post of yours http://www.diyaudio.com/forums/planars-exotics/192303-curved-vs-flat-esl-panels.html back in 2011 when you considered curved versus flat panel ESLs. You succinctly described the performance of a flat panel thus: "a flat panel's sweet spot [is] very pronounced and only about as wide as the panel itself". At that time you were considering building a segmented ESL in order to gain a wider sweet spot. Now that you have done this, it would be very interesting to hear how you would describe the width of the wide dispersion mode in your ESL. How does it compare with the width of the panel?

Hi ENCR,

My old perf metal panels sounded just as wonderful as I described them in the post you referenced. And my new segmented wire panels sound fantastic too—not better, just different. Comparing the two is really an apples and oranges analogy.

When building the new segmented wire panels I had concerns about increased mechanical vibrations resulting from their much lower mass and whether the resistor network might degrade the purity of the sound. Surprisingly I can’t hear the resistors at all—no adverse effects, only wider dispersion.

And when I place my hand on the panel while it’s playing, I feel it’s lattice structure vibrating like crazy, yet I don’t hear the vibration, or at least nothing objectionable. All of my fears about the new panel were unfounded.

Not to mention they are sexy looking and I’m sure, much more robust—I can play them as loud as I want with absolutely no fear of arcing. The hardest part of building them was designing the stretching jig.

As compared to the perf metal panels, they have the same spooky clarity, imaging at the focal sweet spot is quite good although a bit less precise, they have a bit less slam (at the focus) yet can still play painfully loud without strain. The segmented panels project a nice wide sweet spot and there is a wonderful sense of spatial ambience. All things considered, I think I now prefer the segmented panels.

Regards,

Charlie

Thanks for your information. You also mentioned back in that 2011 post that the panels gave a sweet spot only wide enough for one seat. Do you now find with the symmetrically-segmented panel that someone can sit next to you and still get the "sweet spot"? Previously you jokingly wrote that someone would have to sit on your lap! I understand the technicalties behind these differences; it is your impression of the results which interest me.

Thanks for your information. You also mentioned back in that 2011 post that the panels gave a sweet spot only wide enough for one seat. Do you now find with the symmetrically-segmented panel that someone can sit next to you and still get the "sweet spot"? Previously you jokingly wrote that someone would have to sit on your lap! I understand the technicalties behind these differences; it is your impression of the results which interest me.

The sweetspot is now at least as wide as my sofa with no perceptible edge.

No disrespect, but it takes almost no time at all to demonstrate these conditions by testing dreadful old flat panels and wonderful new curved panels, using REW and a mic in left, right, and centre locations on your sofa.The sweetspot is now at least as wide as my sofa with no perceptible edge.

Piece of cake to measure beaming frequency response.

B.

No disrespect, but it takes almost no time at all to demonstrate these conditions by testing dreadful old flat panels and wonderful new curved panels, using REW and a mic in left, right, and centre locations on your sofa.

Piece of cake to measure beaming frequency response.

B.

I don't have the measuring tools you referenced so I' can only provide a less meaningful answer to the question.

Last edited:

Thank you for quick reply.I don't have the measuring tools you referenced so I' can only provide a less meaningful answer to the question.

I'd be glad to see anybody post any useful data on this matter that bothers a lot of ESL DIYers.

All you need is any mic and almost any kind of sound stimulus. Just place the mic at two or three properly chosen locations around an arc at almost any distance.

(My panels have the cells in a segment of a cylinder so hard to interpret the resulting curves. But maybe I should try.......)

B.

Thank you for quick reply.

I'd be glad to see anybody post any useful data on this matter that bothers a lot of ESL DIYers.

All you need is any mic and almost any kind of sound stimulus. Just place the mic at two or three properly chosen locations around an arc at almost any distance.

(My panels have the cells in a segment of a cylinder so hard to interpret the resulting curves. But maybe I should try.......)

B.

I think there are many many many threads about dispersion. also Bolserst made a tool where you can graphical see the difference, feels like you force him to make a measurement 🙂 haha. and by the looks of it i think hes rather done with the project and enjoying them 🙂

Try to use the search page, many threads about segmented esl's will end up in directivity threads , as well as the curved panels threads 🙂

- Home

- Loudspeakers

- Planars & Exotics

- About to take the ESL plunge