Hi, I've opined that shiploads of the stuff have come onto China's idlefish market (eBay-alike). I first couldn't resist a bargain single 8" 4-screw "innie", which didn't move me, then for "research-sake" talked down a single 8" 8-screw "outie", which blew me away! Surprising; two drivers looked the same otherwise, alnico round butt 8-ohm. Plan for them is ~14L (half-cubic-foot) Aperiodic oldlook-radiobox which I have several pairs on hand. Not big enough?

Last edited:

Do you know the make and model of the drivers you intend to use, wchang?

I'd love to see some photographs.

Aperiodic loading can allow an enclosure smaller than the corresponding sealed enclosure to be used.

Photographs of your "aperiodic oldlook-radiobox" would also be welcolmed.

I'd love to see some photographs.

Aperiodic loading can allow an enclosure smaller than the corresponding sealed enclosure to be used.

Photographs of your "aperiodic oldlook-radiobox" would also be welcolmed.

Backs look the same. The cabs actually are made to hold/convert car radios (now include CD/USB/etc), nice thick wood dovetails. I bought eight for $115 much of it shipping. Just add baffle & back. Two pairs are earmarked for my push-pull LorenzGraetz-Goodmans 7x10s, look absolutely custom fitted and sound jaw-dropping perfect. Temporarily on hold due to Covid measures.

Wow! Really old Wharfedales!

From what material is the cone surround made in each case?

The enclosures look promising.

From what material is the cone surround made in each case?

The enclosures look promising.

Both oil-cloth. I paid ~$75 to try one then ~$100 to "test" whether innie and outie sounded the same 😉

It's finally clicked with me - "outie" and "innie" means convex and concave roll surrounds respectively! 😎

I'll see if it's possible to identify the model of these drivers later.

Happily, for your purposes, they look designed to have a low free air resonance frequency.

I'll see if it's possible to identify the model of these drivers later.

Happily, for your purposes, they look designed to have a low free air resonance frequency.

Hi wchang!

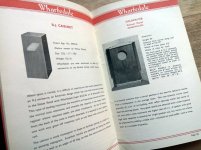

Your 8 hole fixing driver appears to be a Wharfedale Super 8/CS/AL (CS for cloth surround and AL for aluminium voice coil).

It's shown at the top right of the attached flyer. Cone resonance 60-65 Hz and frequency response 50-15,000 Hz.

Your 8 hole fixing driver appears to be a Wharfedale Super 8/CS/AL (CS for cloth surround and AL for aluminium voice coil).

It's shown at the top right of the attached flyer. Cone resonance 60-65 Hz and frequency response 50-15,000 Hz.

Attachments

You can download information about the Robbins-Joseph (R-J) Cabinet from here: https://www.bbc.co.uk/rd/publications/rdreport_1955_08

I see that the enclosure described in the download is for a 12" driver, however it could be scaled for an 8" driver.

I see that the enclosure described in the download is for a 12" driver, however it could be scaled for an 8" driver.

Last edited:

The 4 hole fixing driver with the same alnico magnet system could be the Super 8/CS listed above the Super 8/CS/AL in the price list.

That driver doesn't have an aluminium voice coil, so will have a less extended high frequency response than the AL version.

That driver doesn't have an aluminium voice coil, so will have a less extended high frequency response than the AL version.

I’ve mounted the bracing in both cabs, have started on the frame for the back panels and drilled the driver mounting holes ….probably gonna take me longer than I thought to complete these..but they are moving fwd.

Attachments

Fantastic detective work! Thank you Galu. When I compared them side by side before the (almost) just-ended Covid lockdown, my 59-year-old ears had not noticed a HF tilt to one side, but the ID'ed 8-hole outie Super-8 was smoother and more natural. It's possible the cheaper 4-hole innie was a bit off spec. Vintage Wharfedale are relatively rare on idlefish compared to Goodmans or German brands.

...they are moving fwd.

They certainly are ... and looking good!

Must have been chilly work, since it reads zero degrees on your outdoor thermometer!

Cannot have too many clamps. But almost there.I’ve mounted the bracing in both cabs, have started on the frame for the back panels and drilled the driver mounting holes ….probably gonna take me longer than I thought to complete these..but they are moving fwd.

I like slot-loaded port because it's super easy to insert divider boards (especially cardboard, incrementally) and try out different length/shape "TLonken" hybrid geometry in real time.

Last edited:

PS the manual you linked references celotex so I’m thinking it’s the crepe paper like stuffing in my Cotswolds.

The manual states that the plywood panels are lined with 1/2" celotex and lagged.

Further research reveals that celotex is a type of building board which Wharfedale used to damp resonances of the enclosure's plywood walls. Celotex is mentioned in Briggs' Cabinet Handbook and I take to have a soft, fibrous nature. Low density fibreboard may fit the bill.

"Note how the Celotex lining destroys the regular harmonics of the plywood vibration."

The "lagging" on top of the celotex is sound absorbent material, such as BAF or your Polyester wadding.

I read in the Cabinet Handbook that lining a removable back with celotex or building board helps prevent it vibrating.

"It should be remembered that the cabinet back is usually the largest panel in the structure and is therefore the most resonant ... A combination of plywood and building board well glued and pinned together reduces resonance without increasing weight."

That's an addition to the removable back you may wish to consider at a later point.

Last edited:

Thanks. I have big roll of 1” Polyester wadding and am working on the principle that as I used 15mm ply and not the 12mm mentioned in the handbook and added the bracing shelf that will hopefully be enough. If not I can add something later for sure. What would be a modern equivalent like foam board? Or expanded polystyrene? (I actually have a load of polystyrene panels in the loft). Back at work tomorrow so progress is going to slow.The manual states that the plywood panels are lined with 1/2" celotex and lagged.

Further research reveals that celotex is a type of building board which Wharfedale used to damp resonances of the enclosure's plywood walls. Celotex is mentioned in Briggs' Cabinet Handbook and I take to have a soft, fibrous nature. Low density fibreboard may fit the bill.

The "lagging" on top of the celotex is sound absorbent material, such as BAF or your Polyester wadding.

I read in the Cabinet Handbook that lining a removable back with celotex or building board helps prevent it vibrating.

That's an addition to the removable back you may wish to consider at a later point.

Thanks. I have big roll of 1” Polyester wadding and am working on the principle that as I used 15mm ply and not the 12mm mentioned in the handbook and added the bracing shelf that will hopefully be enough. If not I can add something later for sure. What would be a modern equivalent like foam board? Or expanded polystyrene? (I actually have a load of polystyrene panels in the loft). Back at work tomorrow so progress is going to slow.

Ahh oh sorry I see you already made a suggestion re an alternative.

What would be a modern equivalent...?

I think your 15 mm ply structure will be pretty vibration resistant as it is. Even the removable back, particularly if it is braced by the bracing shelf.

I think Wharfedale's 'celotex' may have been a building board made from pressed wood fibres (not from wood chips like chipboard). I've got such boards under the tiles in the roof of my loft. I would not expect poystyrene panels to provide a high degree of panel damping. They may simply take up valuable internal volume to no great advantage.

Modern Celotex is described as a "rigid polyisocyanurate (PIR) insulation board with a low emissivity aluminium foil facing". This is highly unlikely to be the same as the "building board" or "celotex" mentioned in the 1962 edition of the Cabinet Handbook. It's obviously ideal as a thermal insulator, but may be less than ideal for damping panel vibrations.

I'm thinking standard hardboard panels, aka Masonite, may do the job - but only if required. https://en.wikipedia.org/wiki/Masonite

Attachments

Last edited:

- Home

- Loudspeakers

- Full Range

- A blast from the past …Wharfedale 1cu ft cabinets