Saw a commercial amp made in the USA touting the power output for a KT88 push pull at 90wpc. Am no expert, but how can you get 90wpc from a push pull KT88? 🙂

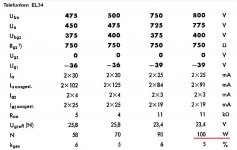

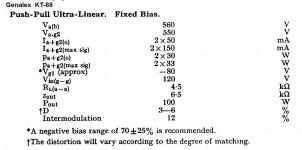

You get that much power by beating the living guano out of the tubes. 🙁 Refer to this KT88 datasheet. Also, the KT88 is rated for Class "x2" operation.

While it can be done, it is (IMO) most definitely not a good idea.

While it can be done, it is (IMO) most definitely not a good idea.

No problem.Saw a commercial amp made in the USA touting the power output for a KT88 push pull at 90wpc. Am no expert, but how can you get 90wpc from a push pull KT88? 🙂

You can even get 100w from a pair of el34, maybe not that long but it has been done.

You can even get 100w from a pair of el34...

Yes, with 1000 V as anode voltage.

http://www.morsegroup.eu/geloso/Bo71-72.pdf

If you choose the right load, screen voltage, and B+, it is easy to get 100W out of a pair. You probably can't bias too hot because you will be working with a pretty high B+, but it is certainly easy to work out the conditions.

And like it was stated above, you could do the same with EL34s; you would just have to bias even colder since you have to respect the max dissipation rating.

And like it was stated above, you could do the same with EL34s; you would just have to bias even colder since you have to respect the max dissipation rating.

You don't even need that 1kV.With the KT-88 no problem, UL.Yes, with 1000 V as anode voltage.

Mona

Attachments

Last edited:

with new production tubes, i seriously doubt it.....

the problem i see is the pin 3 to pin 2 arc-over as you raise the B+ to such high levels...

it happened to me once in an el34 pp amp running 450 volt B+...

but with tv horizontal tubes with plate caps or with plates far from the filaments like

in a compactron tube, maybe....George has many examples in this board...

the problem i see is the pin 3 to pin 2 arc-over as you raise the B+ to such high levels...

it happened to me once in an el34 pp amp running 450 volt B+...

but with tv horizontal tubes with plate caps or with plates far from the filaments like

in a compactron tube, maybe....George has many examples in this board...

I run KT90's & KT88's at 600V B+ in my 250W amps and use old phenol IO bases...never had any arc jump between heater(2) and anode (3). I'm sure the designers of the tube would have reverted to it's top cap anode, i.e TT versions should it been a problem.with new production tubes, i seriously doubt it.....

the problem i see is the pin 3 to pin 2 arc-over as you raise the B+ to such high levels...

it happened to me once in an el34 pp amp running 450 volt B+...

but with tv horizontal tubes with plate caps or with plates far from the filaments like

in a compactron tube, maybe....George has many examples in this board...

rich

^i used an oled 'cinch' octal socket.......replaced it with a new one and put silicon sleeve over the #3 pins and problem solved...

So the arcing takes place at the socket pins and not inside the tube? Does that mean the modern power tubes can handle the rated HV (or relatively close to the spec)?

the problem i see is the pin 3 to pin 2 arc-over......So the arcing takes place at the socket pins and not inside the tube?

Arc over, or operation at 100 watts per pair should not be an issue in a HiFi amplifier which rarely sees clipping and operates into a well matched load. The average power output in a 100 watt amp is usually well below 5 watts. The worst case voltage seen at the plate is 2 X B+.

A guitar amp running into clipping nearly constantly is a different matter. The resonant impedance peak of a guitar speaker is within the guitar's frequency range, right about where a "chugga chugga" metal player hits it. The load impedance here is maybe 30 ohms, highly reactive. I have measured (resistive divider feeding my scope) over 2 KV peaks on an amp running 450 volts of B+.

I have seen arc over happen in 3 places in a guitar amp.

The arc is usually between pins 2 and 3 on the base of the tube sockets. Ceramic sockets, even the cheap Chinese ones will live forever (other parts may not), but the common black bakelite old production sockets will eventually carbon track and burn creating a low resistance path frying the rectifier tube, the OPT, and sometimes the power transformer (where the user installed a bigger fuse).

I have seen the arc occur inside the base of the tube between pin 3 (plate) and pin 2 (heater) or the metal base ring on some KT88's. This usually happens on dirty amps used in damp places (outdoors in Florida). An arc will not happen inside the tube if there is a good vacuum inside. It is possible to ionize the "gas" inside a bad tube with excessive plate voltage, but it takes a really BAD tube, and some abuse (see picture).

Sometimes the arc occurs INSIDE the OPT. You can't see it, but you will find a fried OPT if you take it apart after replacing it....because its dead.

I have found a blown 12AX7 once due to an arc in an amp I made (relatively docile 30 watts). It was due to an arc between pins 3 and 2 at the socket on the 6L6GC. The heater winding was elevated with the usual two resistors and cap. All three were blown, then the arc moved into the 12AX7 taking out the heater. The user was running 16 ohm speakers on the 4 ohm tap because he liked the cool "distortion" the amp made. The distortion was due to an arc over at the base of a ceramic socket on one output tube. He had been doing this for nearly a year, and surprisingly nothing else was blown. The OPT was one of the paper Schumakers that I have been using for years (I set one on fire when the dummy load went open at about 120 watts). A new 12AX7 and a solidly grounded heater winding made him happy. The power transformer was from an old HP audio oscillator....they are nearly impossible to blow....I have tried!

Attachments

I am finally building a new lab after moving twice in the past two years. I got to do a couple of experiments last month, and one of them involved reviving an old breadboard from about 8 years ago in the 6L6GC in AB2 design thread. I stuck some 20 year old Chinese KT88's into it and cranked them up to 100 watts on 525 volts. I let them run until the load resistor got too hot to touch. The OPT is another of the same paper Schumakers wired for 3300 ohms.

Note the purple glow inside the KT88's is not real. The camera "sees" infrared as purple. The same color can be seen on the heaters of the clear top 6CG7.

See this thread if interested. I tested several tubes with a similar set up back 7 or 8 years ago. This round starts in post #648. I tend to start by repeating old tests with familiar tubes to verify the set up. More will come as I get stuff back together.

http://www.diyaudio.com/forums/tubes-valves/133034-6l6gc-ab2-amp.html

Note the purple glow inside the KT88's is not real. The camera "sees" infrared as purple. The same color can be seen on the heaters of the clear top 6CG7.

See this thread if interested. I tested several tubes with a similar set up back 7 or 8 years ago. This round starts in post #648. I tend to start by repeating old tests with familiar tubes to verify the set up. More will come as I get stuff back together.

http://www.diyaudio.com/forums/tubes-valves/133034-6l6gc-ab2-amp.html

Attachments

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- 90wpc from push pull KT88?