That is good idea.

If you do not copy the original idea of the base, I think you have two options: either design really simple, or rough. My first plan was to use concrete. Easy to shape, heavy, and it would make a good contrast to glossy, smoothly shaped baffle.

My statement is this; if somebody is hearing difference between power cords, I am hearing difference between pleasing and not pleasing designs, considering outlook. At least in my own living room.

I'll fill the base with sand, so it will weigh about 20 kilos. Plus baffle and speakers 20 kilos, it will make 40 kilos which would be good enough.

If I had iron foundry, I would cast the base from iron. But I do not have it. 🙂

If you do not copy the original idea of the base, I think you have two options: either design really simple, or rough. My first plan was to use concrete. Easy to shape, heavy, and it would make a good contrast to glossy, smoothly shaped baffle.

My statement is this; if somebody is hearing difference between power cords, I am hearing difference between pleasing and not pleasing designs, considering outlook. At least in my own living room.

I'll fill the base with sand, so it will weigh about 20 kilos. Plus baffle and speakers 20 kilos, it will make 40 kilos which would be good enough.

If I had iron foundry, I would cast the base from iron. But I do not have it. 🙂

Last edited:

Have you thought about stone?

Often stonemasons have off cuts or cut-outs or pieces left over from a consignment.

Having two pieces cut, polished and drilled might be cheaper than you imagine.

Doug

Often stonemasons have off cuts or cut-outs or pieces left over from a consignment.

Having two pieces cut, polished and drilled might be cheaper than you imagine.

Doug

Bonding stone to wood ...

... isn't difficult if you select the appropriate adhesive.

Here's a coffee table I made from an off-cut piece of granite. I had the stonemasons just square the edges and polish them. Cheap.

I can imagine a granite and wood base would look great.

Doug

... isn't difficult if you select the appropriate adhesive.

Here's a coffee table I made from an off-cut piece of granite. I had the stonemasons just square the edges and polish them. Cheap.

I can imagine a granite and wood base would look great.

Doug

Attachments

Nice table you have there!

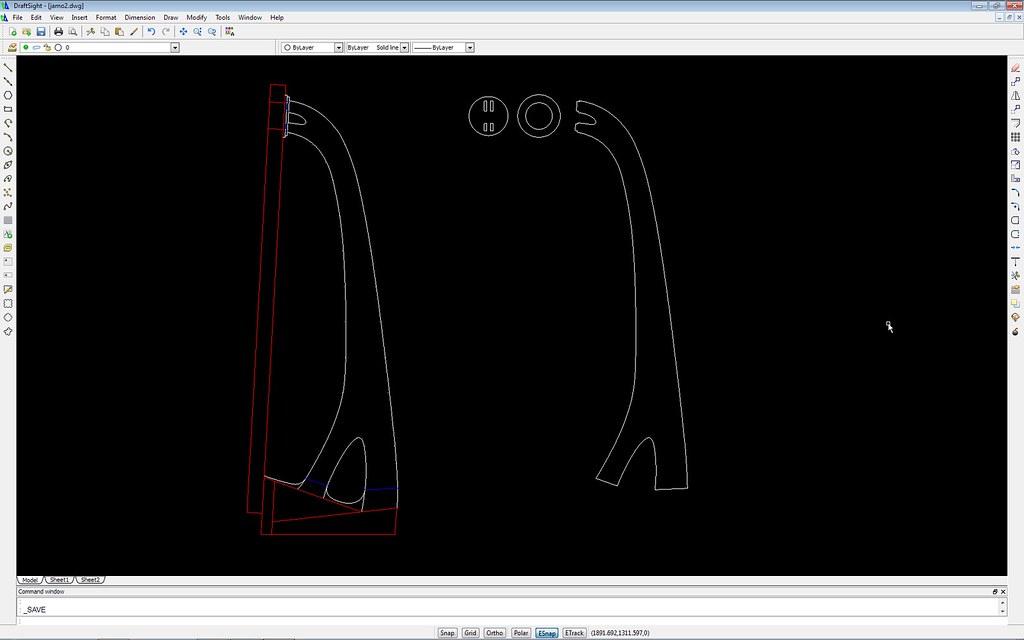

I ´d like to make so exact copy as possible, and have already designed the base:

I ´d like to make so exact copy as possible, and have already designed the base:

Last edited:

Alpha 15a, Seas L15LRY, Vifa XT25TG30.

These drivers are not match with sensitivity !

Two alpha 15a will give after equalization 96dB/2.83V !

XT25 93dB/2.83V

L15RLY 85dB/2.83V

You need at least a 5" with 93dB/2.83V !

Thanks for kind words, Surv1v0r! If I had the plane, there would be no other choice, would it?! 🙂

Unfortunately (?), I don't have it. I have restored couple of boats from allmost that era, though. 🙂

And thanks for the advice, jerome69!

Sizewise it is not possible to change anything anymore.

Midrange could be changed to Seas ER15RLY or CA15RLY with 87.5 dB. Or some other with same price tag, about.

I've learned that in open baffles there should be clear difference (~10 dB) between sensitivity of woofers and midrange/tweeter. In this case tweeter could easily be tamed little bit, as needed.

I allready have those Vifas, that's the reason for using them, but if they don't work they have to be changed.

I'm not very demanding ar this point. If they sound good to my ears, that's good enough for now.

Unfortunately (?), I don't have it. I have restored couple of boats from allmost that era, though. 🙂

And thanks for the advice, jerome69!

Sizewise it is not possible to change anything anymore.

Midrange could be changed to Seas ER15RLY or CA15RLY with 87.5 dB. Or some other with same price tag, about.

I've learned that in open baffles there should be clear difference (~10 dB) between sensitivity of woofers and midrange/tweeter. In this case tweeter could easily be tamed little bit, as needed.

I allready have those Vifas, that's the reason for using them, but if they don't work they have to be changed.

I'm not very demanding ar this point. If they sound good to my ears, that's good enough for now.

What am I seeing in the upright leg? Is there a black layer between two layers of aluminum or just a stripe? Love the stepped detail on the top end cap!

David

David

Its a gap. Tongues of the upright pieces that go through the smaller plate are a bit too long, for now- they will be trimmed down so that there will be no gap. Tongues will be welded to first, smaller plate, and that will be welded to the bigger plate and then the whole thing will be screwed to the baffle. Weldings are inside, so there will be no visible welding seams.

Reason for stepped plate is that the tweeter is few millimeters deeper than the baffle is thick, so there´s big hole in the first plate and that leaves enough room for it.

Therefore, it´s functional, too.

Reason for stepped plate is that the tweeter is few millimeters deeper than the baffle is thick, so there´s big hole in the first plate and that leaves enough room for it.

Therefore, it´s functional, too.

Last edited:

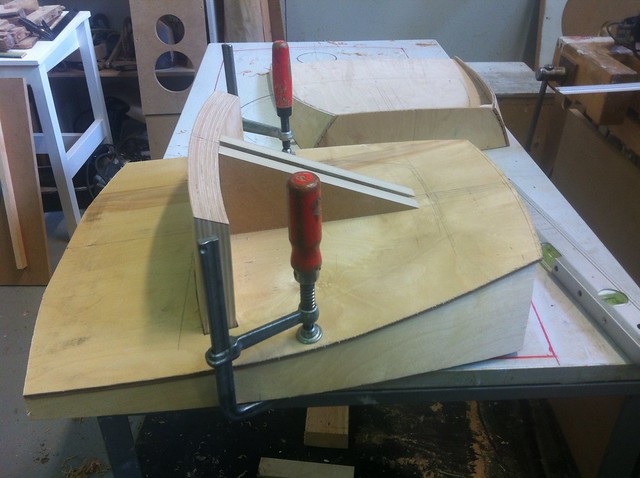

Filled with sand and the top cover glued in place. Planning the topside box for crossoverparts.

Not so satisfied to it. It should be curved, but too late to change it now... Or not maybe too late, but I´m just not up to it.

The stand alone weighs little over 14 kilos, or 30 pounds. The whole thing together, with baffle, back support and speakers, is going to weigh about 40 kilos, or 88 pounds.

Not so satisfied to it. It should be curved, but too late to change it now... Or not maybe too late, but I´m just not up to it.

The stand alone weighs little over 14 kilos, or 30 pounds. The whole thing together, with baffle, back support and speakers, is going to weigh about 40 kilos, or 88 pounds.

- Home

- Loudspeakers

- Multi-Way

- 909 clone