Hi Fluid, all my issues were generally from stls being hollow and being unable to do much with them, although sometimes it would work, which encouraged me to struggle with them for longer than I should, even using blender to thicken them , etc. Currently I only use the profiles for making seams between parts and for easier generation of ribs for stiffening, otherwise all work is with slices. Currently I have quite a few components with many different set of slices and performance is smooth for most stuff. Completely different experience than when working with the meshes... I presume it is just how fusion handles meshes/stl's as I have a powerful machine and other programs like blender don't have the same issues.For lofting you only need the slices, you can have Ath output, slives, profiles or both. More points is not better, you only need enough to properly define the splines. More slows everything down and bogs the scripts to no positive end. Just the same with STL's and simulation, too much angular resolution does nothing helpful. Almost all of your struggles will stem from these two things.

One thing I have noticed is that sometimes the fitted spline gets a little off target.

Have you seen this before? Looks like its the profile that is off, but the fitted spline runs through the points?

Last edited:

I thought STL's might have been a typo as the images were splines. Fusion really does not get on that well with meshes, and high triangle count ones will often crash it. Solid geometry or surfaces work much better.

Sometimes things look different than they are, the projected surface may not match or change when you zoom in and out.

This code in the cfg file will get the proper csv file for slices to work with the Ath surface plugin.

GridExport:f360 = {

ExportProfiles = 0

ExportSlices = 1

Scale = 0.1

}

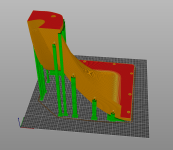

This is the 4ndf file fom your github with 64 angular segments, I don't see one that has the same throat shape as in your images but this should still be enough resolution for that. I have attached a fusion file with a 5mm thickened version of it. With the right workflow it only takes a few minutes.

Sometimes things look different than they are, the projected surface may not match or change when you zoom in and out.

This code in the cfg file will get the proper csv file for slices to work with the Ath surface plugin.

GridExport:f360 = {

ExportProfiles = 0

ExportSlices = 1

Scale = 0.1

}

This is the 4ndf file fom your github with 64 angular segments, I don't see one that has the same throat shape as in your images but this should still be enough resolution for that. I have attached a fusion file with a 5mm thickened version of it. With the right workflow it only takes a few minutes.

Attachments

Thats weird I just re-downloaded it from diyaudio to check I had uploaded the right version and it worked fine for me. I run it via utilities -> addins -> my scripts. Is it possible you are running the original Ath version as it has the same name?Thanks for that, I did try your script too have a look and had a few issues, I am currently happy with where my process is at for this project so dont lose any sleep trying to debug it for me. 🙂

I thought STL's might have been a typo as the images were splines. Fusion really does not get on that well with meshes, and high triangle count ones will often crash it. Solid geometry or surfaces work much better.

Sometimes things look different than they are, the projected surface may not match or change when you zoom in and out.

This code in the cfg file will get the proper csv file for slices to work with the Ath surface plugin.

GridExport:f360 = {

ExportProfiles = 0

ExportSlices = 1

Scale = 0.1

}

This is the 4ndf file fom your github with 64 angular segments, I don't see one that has the same throat shape as in your images but this should still be enough resolution for that. I have attached a fusion file with a 5mm thickened version of it. With the right workflow it only takes a few minutes.

View attachment 1193050

I think you are right, it seems that it was only a visual artifact and the solid body is correct

I have been working on the mouth section and getting it ready to print. This section starts 100mm from the CD throat, allowing me to iterate with CD/mid mounting as long as the overall waveguide stays the same.

First print has turned out ok for a prototype. Took 10 hours, 600g filament. Printing the second piece now, we will see if the mating parts fot together well...

Just read you have a Voron. Nice! That's the one I'd like to build. I'm using two inexpensive Elegoos right now. Started with Lulzbot but failures were too painful on large prints when you are hours into the job. Voron would be far less failure prone because the plate doesn't move and you can keep ambient temp more consistent. I print in small sections with the two Elegoos to avoid catastrophic failure then superglue the pieces together. I'd love to be able to break print jobs up between multiple Vorons.

Welcome along for the ride CinnamonRolls! Vorons are great, they are not however fool proof ( I dont think any FDM printing is). I currently have 2 of the parts printed and have had an extruder issue. This may take me a few days to get things back up and printing as I have a lot on at the moment. 🙂

For those looking at this project you may want to use a process native to fusion to make the thickenss in the waveguide. The method I used is ok for the throat but ends up too thin once we get to the flare. I have experimented with a scale in 2D that worked ok for the flare but was no good for the throat. I have yet to use a method that I think is properly suitable. I think the method fluid used (thicken??) up a few posts is probably the way to go. 🙂

There are various methods that work depending on what you want to achieve. I used thicken as an example and it is easy if all you want is the surface face made exactly the same to a given thickness. You can create different surfaces for the rear section with sketches, sweeps and lofts and then stitch them together to form a solid. Some things are easier to make as a surface, some as solid. Once you have the basic surface in Fusion you can project any of the profiles. The Mouth and throat can be patched and the surafaces stiched to make a plug which can then be cut from a larger solid block. It all depends on what you want the outside shape to be.

The key is to get the waveguide surface lofted into a whole. For non axisymmetric guides made with Ath, the surface plugin and slices made with the code above are the easiest way to do that.

The key is to get the waveguide surface lofted into a whole. For non axisymmetric guides made with Ath, the surface plugin and slices made with the code above are the easiest way to do that.

Wow, this is pretty cool..following your progress with interest (along with an increasing list of exciting MEH threads). All these 3d printed MEHs are making me lament my elegoo Neptune 3...I need a bigger build plate to join the fun!

Looks like I may be doing a bit of a redesign. First off I will be focussing on designing a OS(ish) horn/waveguide to experiment around with HF/mid crossover using the same components. Goal is to see how high I can get it, without wasting plastic on a large horn.

- Home

- Loudspeakers

- Multi-Way

- 60x40 - MEH - DE250 - 4NDF34 - 3D Printed project - Mid/Hi - 600hz to 20khz