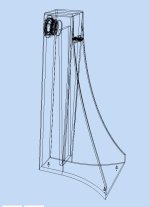

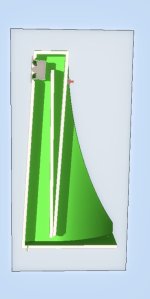

This is XRK971 version of frugal horn lite. The rear wave guide is a little large than the original foam core build. I used 12 mm walls and is printed in two pieces to fit on my build plate and to stuff it with acoustistuff. I hope to do a sound test this weekend. Still have to print a second enclosure. At the seam, construction is tongue and groove to align perfectly. Once’s sealed, it will be light sanding and will be primer and painted. The bottom has 3 threaded hole for spikes.

Tony

Tony

Attachments

-

IMG_1257.jpeg534 KB · Views: 160

IMG_1257.jpeg534 KB · Views: 160 -

IMG_1255.jpeg628.7 KB · Views: 155

IMG_1255.jpeg628.7 KB · Views: 155 -

IMG_1253.jpeg545.1 KB · Views: 149

IMG_1253.jpeg545.1 KB · Views: 149 -

IMG_1251.jpeg599.1 KB · Views: 155

IMG_1251.jpeg599.1 KB · Views: 155 -

IMG_1248.jpeg182.2 KB · Views: 152

IMG_1248.jpeg182.2 KB · Views: 152 -

IMG_1250.jpeg240.6 KB · Views: 140

IMG_1250.jpeg240.6 KB · Views: 140 -

70423686750__1759BA07-4732-4C98-9210-ABD6F8D6EF39.jpeg235.9 KB · Views: 130

70423686750__1759BA07-4732-4C98-9210-ABD6F8D6EF39.jpeg235.9 KB · Views: 130 -

IMG_1219.jpeg73 KB · Views: 151

IMG_1219.jpeg73 KB · Views: 151 -

IMG_1225.jpeg40.1 KB · Views: 148

IMG_1225.jpeg40.1 KB · Views: 148

This is XRK971 version of frugal horn lite

It was a good pre-amble. Best to fo the one properly modeled and designed and not Xs scaled imitation.

But seeing one 3D printed is special. What printer? One piece?

dave

My 3d printer is the Anycubic Kobra Max. It was printed in two pieces to fit on my build plate and so I can put the acoustic stuffing like the design is called for. I modeled it up based on the drawing of the original furgal horn lite drawing and the played with the back end design. Everything else was per the original drawings. The two pieces is tongue and groove so it fits perfectly together.

Tony

Tony

Lovely speaker, looks already great as it is. More and more 3d printed speakers keep popping up 👍

Great work, although for clarity, and in fairness to him I should say that X's is entirely his own design: it's not a version of FH-lite.Thank you, the furgal horn family is a proven design and I like the way it is shaped with the curved back. Here other enclosure and baffles that I have printed.

Tony

Last edited:

I apologize, you are correct, this is not a version of the Frugal horn lite. I don’t know what to call tho.

Tony

Tony

That looks nice! How long did it take to print the two pieces?

I‘m looking forward to reading about the sound tests that you make.

I‘m looking forward to reading about the sound tests that you make.

I really like that print. That is a large scale print. I have been printing smaller waveguides myself with some success. I recently found a printer mod that can reduce variation in the sides. Here is a link to a video explaining the mod. It seeks to reduce the variation in the Z step sizes. I'm going to try it on my printer.

Thanks, the bottom base took about ten day printing non stop and the top half took almost 6 days.That looks nice! How long did it take to print the two pieces?

I‘m looking forward to reading about the sound tests that you make.

tony

- Home

- Loudspeakers

- Full Range

- 3d printer (not-quite) Frugel-Horn Lite