Plastic will sound like plastic.

Wood will sound like wood.

Depends on how it is designed, the box should have no sound of its own.

dave

Hello,

I've just completed my first DIY speaker "9-cells Pipe Array" speakers made by 3D printed PLA.

When well designed, 3D printed enclosures are as tough and inert as the best loudspeakers, as already highlighted by other members...

It's all about engineering the shape/thickness with a little bit of ingenuity.

Perhaps I'll work on a new version (with more drivers?) to rise a little bit the bar 😉 .

Very satisfied with the preliminary results so far.

Manuele

I've just completed my first DIY speaker "9-cells Pipe Array" speakers made by 3D printed PLA.

When well designed, 3D printed enclosures are as tough and inert as the best loudspeakers, as already highlighted by other members...

It's all about engineering the shape/thickness with a little bit of ingenuity.

Perhaps I'll work on a new version (with more drivers?) to rise a little bit the bar 😉 .

Very satisfied with the preliminary results so far.

Manuele

The abs printers that are common, won’t have much strength. That can be improved by lightly brushing mek to help fuse the layers on the surfaces.

What would be better is to use the technology to gain the nice geometry, then use it to create molds. Then use a fiberglass, hydrocal, or other molded process.

What would be better is to use the technology to gain the nice geometry, then use it to create molds. Then use a fiberglass, hydrocal, or other molded process.

It's a PLA print with the inside lined with SikaDamp constrained layer dampening pads.

Last edited:

Some measurements were made in the video to examine wall infill and resonance.

I thought it was interesting, although I wasn't surprised with the results.

I thought it was interesting, although I wasn't surprised with the results.

I’ve read about using plaster Paris mixed with some PVA glue as being a good option for filling 3-D printed speakers

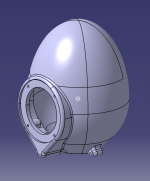

This is not true. I can make an egg shape with a saw a rasp and a vise in about 20 minutes. They can be fabricated easily by hand with nothing more than sandpaper in about an hour and a couple of beers. Making something twice as big as an ostrich's egg is more challenging but not out of reach of the average wood turner or composite fabricator and won't take 4 days of printing. Printing is just in style right now.also hard to make an egg shape without CNC

No, no, no! Not heavy, but stiff! Fill them with plaster, gypsum, or polyurethane foam. Sand works a different way, by the sand grains slightly rubbing each other and absorbing the vibrations.I don't see a reason why it wouldn't work.

Like someone said earlier, you'd need to fill the enclosure with something heavy.

Sand and/or concrete comes to my mind.. unless you'll have some nasty cabinet resonances I fear

Also, the egg shape is inherently strong, it doesn't have to be thick and heavy. Just ask a chicken.

I suppose a hypercube or tesseract enclosure could be 3D printed - it is like a box with extreme bevels so low diffraction and great imaging. Mine was made with foam core but this is the perfect size for 3D printing. You could even print internal bracing and keep wall thickness very thin to save on filament.

More info on the hypercube geometry.

https://www.kjmaclean.com/Geometry/rhombicdodeca.html

More info on the hypercube geometry.

https://www.kjmaclean.com/Geometry/rhombicdodeca.html

- Home

- Loudspeakers

- Full Range

- 3D printed speaker enclose; thoughts ?