Is a 3D printed pulley smooth/accurate enough to use? I'm thinking about having a nylon pulley made for a AR (larger hole for different motor). Any CAD experts out there?

One would think as long as it's round any small surface grit would be integrated out by the platter flywheel mass...

Turning a part will give far better run-out than printing it, and a much better surface finish. And particularly the centre bore of a 3D printed pulley will be its weak point I suspect, as you probably have to ream this out anyway without a reference axis, leading to the risk of having the hole not quite normal to the plane of the pulley groove...

But what accuracy is required?

[ Delrin is preferable to nylon if machining/turning BTW as its more dimensionally stable ]

But what accuracy is required?

[ Delrin is preferable to nylon if machining/turning BTW as its more dimensionally stable ]

I second what Mark has to say.

I would be concerned with how round the pulley turns out along with the concentricity of the I.D and the O.D.

I would be concerned with how round the pulley turns out along with the concentricity of the I.D and the O.D.

... Is a 3D printed pulley smooth/accurate enough to use?

The consumer stuff will go down to about 0.1 mm, I think, maybe a bit more or less.

My $800 3D printer will turn out very good parts - small round concentric shafts in a round bushing are not a problem.

My $100 3D printer not so great, small round parts are slightly ovalled because I can't figure out how to get into the firmware to adjust the calibration. This is generally not a problem unless you need something to be accurately concentric.

So, imo, it depends on how well the subject printer that is manufacturing the part is calibrated, and some experience with that printer.

Last edited:

I have no experience or the equipment to print or turn. That's why I asked. I would prefer a Delrin turned pulley, but one off's are expensive. What I want is an AR-AX pulley but with .250 " hole, longer shaft, secured with set screw.

Hello cygnus x1,

Forget about printing. There is no printer accurate enough to print a precision pulley for a turntable. And I don't see how a "one off" can be more expensive than a printed part. You need a solid model for the printer to start with. If you insist on printing your pulley, I can provide you with a solid model and an ANSI paper drawing for free, just provide a sketch with all dimensions.

Sincerely,

Ralf

Forget about printing. There is no printer accurate enough to print a precision pulley for a turntable. And I don't see how a "one off" can be more expensive than a printed part. You need a solid model for the printer to start with. If you insist on printing your pulley, I can provide you with a solid model and an ANSI paper drawing for free, just provide a sketch with all dimensions.

Sincerely,

Ralf

You will need a closely controlled hole diameter to have a good enough fit onto the motor shaft. I cant see the printer achieving this. You could print it with the hole under sized and then run a H7/8 reamer down the hole after.

There is a guy on ebay called techmender who can make you a custom pulley. He recently made me 3 different pulleys for just £25.

tufnol/Nylatron/Steel/brass/aluminium pulley wheel, various sizes made to order. | eBay

There is a guy on ebay called techmender who can make you a custom pulley. He recently made me 3 different pulleys for just £25.

tufnol/Nylatron/Steel/brass/aluminium pulley wheel, various sizes made to order. | eBay

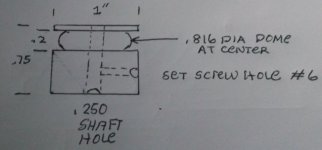

Sorry for the napkin drawing, but this is what I have in mind. Single speed. The only thing not on the drawing is the top "lip" dimension, which I guess could be .0625". Not sure if I want the stock AR length .075" or a 1.5" length, to use with a VPI style sprung to plate.

The pulley "dome" was measured from my AR pulley.

Thanks everyone for your response and insight.

The pulley "dome" was measured from my AR pulley.

Thanks everyone for your response and insight.

Attachments

Update: printed pulley...total fail, out of round. Now looking for some to mill/CNC a brass, aluminum or Delrin pulley. Anyone have any leads?

Turning job for a lathe operator

Shipping will be more than the pulley price!

Seriously, go for stainless steel, it will never corrode.

There was a site called e-machines, a sort of exchange for buyers and sellers of molded and machined parts.

Try there, you may find a willing supplier.

Shipping will be more than the pulley price!

Seriously, go for stainless steel, it will never corrode.

There was a site called e-machines, a sort of exchange for buyers and sellers of molded and machined parts.

Try there, you may find a willing supplier.

Last edited:

There is an engineering firm near where I live that did a great CNC turning job for me at reasonable cost, however, I'm on a different continent to you so the recommendation wouldn't be useful!

I found them by a google search for "CNC turning" or similar search term and my city's name. I had to inquire with a few, and when I got a rejection would ask "do you know who could do this job for me?" which eventually led me to the firm.

I found them by a google search for "CNC turning" or similar search term and my city's name. I had to inquire with a few, and when I got a rejection would ask "do you know who could do this job for me?" which eventually led me to the firm.

- Home

- Source & Line

- Analogue Source

- 3D printed pulley