Standing waves can only be set up under steady state conditions.

The continually changing frequency content of a music signal mitigates against the formation and maintenance of standing waves.

P.S. It is worth bearing in mind that damping and absorption are two different things.

Enclosure walls should be damped while sound energy should be absorbed within the volume of the enclosure.

The continually changing frequency content of a music signal mitigates against the formation and maintenance of standing waves.

P.S. It is worth bearing in mind that damping and absorption are two different things.

Enclosure walls should be damped while sound energy should be absorbed within the volume of the enclosure.

all what you need for damping material----look how Troels G use it in this speaker

The-Loudspeaker

http://www.jantzen-audio.com/wp-content/uploads/2019/08/Damping-Materials.pdf

The-Loudspeaker

http://www.jantzen-audio.com/wp-content/uploads/2019/08/Damping-Materials.pdf

There are no standing waves inside a speaker enclosure. Why you keep tellin' it all the time?!

Not just me, but perhaps better name would be cavity resonance ( Helmholz )

http://www.perfect8.com/nav/pdf/EnclosureBaffleStudies.pdf

Internal standing waves - How to eliminate them from loudspeaker boxes

Theory about speaker+box resonance

Sound - Steady-state waves | Britannica

Last edited:

So here is a bit more information about the box itself. The speaker is inspired by Dynaudio LYD48 with the same driver layout but in a closed box design. the internal dimentions is 37cm wide by 25cm deep and 22cm high. The midrange chamber is 13cm wide by 12cm deep and 22cm high which is cut out of of the woofer box corner.

Im not sure why the image will not open, but just open it in a new tab and you will see the inside of the speaker.

I intend to cross the speaker at 300Hz and 2.5kHz, which means that the woofer box dimensions is smaller than any standing waves.

An externally hosted image should be here but it was not working when we last tested it.

Im not sure why the image will not open, but just open it in a new tab and you will see the inside of the speaker.

I intend to cross the speaker at 300Hz and 2.5kHz, which means that the woofer box dimensions is smaller than any standing waves.

Last edited:

Having seen your image, it would probably prove satisfactory to fill the two chambers behind the woofer chamber with the likes of low density fibreglass, BAF wadding or Polyfill.

In addition, fixing speaker felt to the rear wall may be considered.

In addition, fixing speaker felt to the rear wall may be considered.

Standing waves can only be set up under steady state conditions.

The continually changing frequency content of a music signal mitigates against the formation and maintenance of standing waves...

Enclosure walls should be damped while sound energy should be absorbed within the volume of the enclosure.

All good thoughts, esp bringing the application (music) back into the thread.

But it is an empirical question establishing how much an instrument or orchestra can stimulate oscillations in the system. Certainly those of us who disparage box sound (esp BRs) believe that speaker exaggeration can be triggered a lot. At least for major resonances. Trivial influences like vibrating cab walls may not be worth fussing over.

B.

Examples of working with impedance plots can be found here: https://www.diyaudio.com/forums/full-range/242171-towers-25-driver-range-line-array-62.html#post4140167 for a mid driver and here: https://www.diyaudio.com/forums/full-range/242171-towers-25-driver-range-line-array-555.html#post6017043 is an example done for a subwoofer build.

I'll have to add, I don't rely on the box + driver to shape my frequency curve. So I don't mind if I rob some output here or there. My project uses DSP to shape frequency curves (long story).

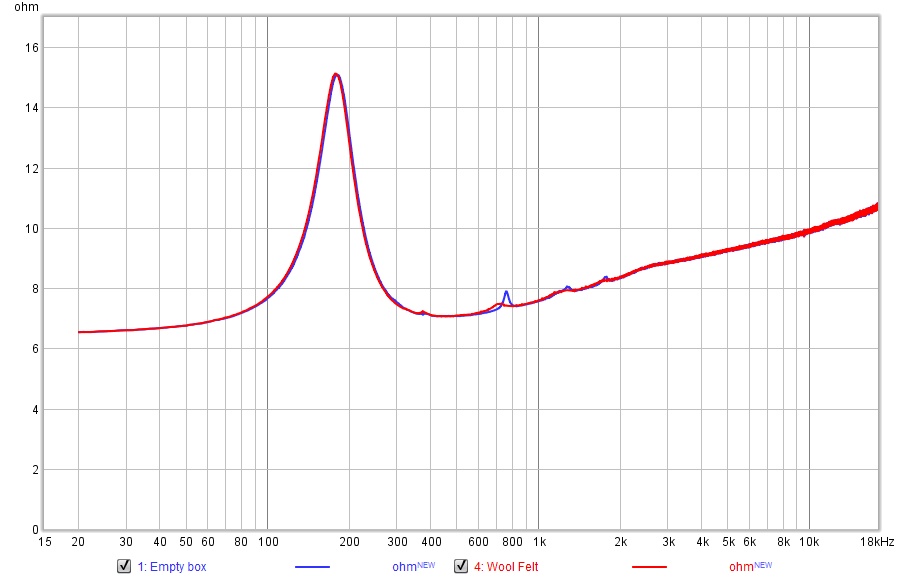

Here's what adding just one layer of 5 to 7 mm (!) thickness of wool felt on the inside walls does, nothing more added at this time:

I really find your work inspiring, and i do consider using some of your findings for my project. Am i to understand that the entire box is filled with sandwich layers of glass wool and wool felt sheets? or do you leave some free air to avoid overstuffing?

Also what would be the main thing that seem to give glass wool the advantage over polyester feltsheets? from what i can find then it seems like the poly sheets have a higher density than standard glass wool of 16kg/m3 vs 60kg/m3 for polyester.

I was looking for other properties than you are for my line arrays. I wanted to bring down the impedance peak in frequency and wanted to use the driver over the full audio spectrum.

The line array enclosure was filled with wool felt on all walls, about an inch of free space behind the magnets of the drivers and wool felt to close off the fiberglass fill underneath.

This use of materials did get the impedance peak lower in frequency so my goal was met. Fiberglass isolation materials are an excellent all rounder in my experience. Working well at all frequencies we humans hear. The combination with wool felt works wonders to remove all traces of wiggles in the impedance curve. Even when a magnified look on the impedance curve is used.

The sub enclosure is filled with wool felt in between the fiberglass, everywhere where a hard surface would follow (like a brace for instance). As that's where it does a real fine job.

Purely for mid enclosures the best material I have seen is Twaron's Angel Hair. Compared to Fiberglass a lot less is needed for it to be effective. It's rather pricey though. It helps to have contacts in that Aramid Industry as I once had 😉. I've done work for that firm in the past.

I have no experience with polyester felt sheets. If you look at the density of Angel Hair, it's even more 'fluffy' than the regular Fiberglass isolation.

The fiberglass is able to bring down the impedance peak (in Hz) about 20% without any overstuffing (loose, non compressed fill). More so than the Angel Hair. However the Angel Hair is superior at mid frequencies. Like I said, a little goes a long way.

Always leave some room for the driver to breathe. A layer of wool felt between the driver and the fiberglass works in two ways. First it stops the fiberglass fibers from reaching critical motorparts, second the wool felt is working better at higher frequencies to absorb and remove impedance wiggles.

Sure there are plenty of other solutions available. I've searched the web before making a rough pick (way back when) and these materials came out on top for me to try.

I never used the Angel Hair but for a pure mid driver I would be tempted. Probably with a layer of (real) wool felt again, as it simply works. Remember, my layer of wool felt is only 5 to 7 mm in thickness, but it's still more effective with it than without.

I've bought a huge roll of that wool from a Frenchman, living in The Netherlands. It still smells like (French) sheep. He sold it as an isolation alternative.

Most people on this forum tend to build (multiple) speakers as a hobby, my idea was to just build one set that will last me a lifetime. So far that works out real good.

The line array enclosure was filled with wool felt on all walls, about an inch of free space behind the magnets of the drivers and wool felt to close off the fiberglass fill underneath.

This use of materials did get the impedance peak lower in frequency so my goal was met. Fiberglass isolation materials are an excellent all rounder in my experience. Working well at all frequencies we humans hear. The combination with wool felt works wonders to remove all traces of wiggles in the impedance curve. Even when a magnified look on the impedance curve is used.

The sub enclosure is filled with wool felt in between the fiberglass, everywhere where a hard surface would follow (like a brace for instance). As that's where it does a real fine job.

Purely for mid enclosures the best material I have seen is Twaron's Angel Hair. Compared to Fiberglass a lot less is needed for it to be effective. It's rather pricey though. It helps to have contacts in that Aramid Industry as I once had 😉. I've done work for that firm in the past.

I have no experience with polyester felt sheets. If you look at the density of Angel Hair, it's even more 'fluffy' than the regular Fiberglass isolation.

The fiberglass is able to bring down the impedance peak (in Hz) about 20% without any overstuffing (loose, non compressed fill). More so than the Angel Hair. However the Angel Hair is superior at mid frequencies. Like I said, a little goes a long way.

Always leave some room for the driver to breathe. A layer of wool felt between the driver and the fiberglass works in two ways. First it stops the fiberglass fibers from reaching critical motorparts, second the wool felt is working better at higher frequencies to absorb and remove impedance wiggles.

Sure there are plenty of other solutions available. I've searched the web before making a rough pick (way back when) and these materials came out on top for me to try.

I never used the Angel Hair but for a pure mid driver I would be tempted. Probably with a layer of (real) wool felt again, as it simply works. Remember, my layer of wool felt is only 5 to 7 mm in thickness, but it's still more effective with it than without.

I've bought a huge roll of that wool from a Frenchman, living in The Netherlands. It still smells like (French) sheep. He sold it as an isolation alternative.

Most people on this forum tend to build (multiple) speakers as a hobby, my idea was to just build one set that will last me a lifetime. So far that works out real good.

Last edited:

I've used old pillows with polyfill! I believe that material mass, placement and density are more important than fibre type.

I'd say that depends on what your goal is. They do act different across the frequency spectrum. I believe loose thin fibers isn't a bad thing depending on your goals. Colakurt has two different enclosures to damp, this might mean a need for different materials as well. Anyway, I let the impedance curve tell me the story, highly recommended.

It isn't that hard to measure impedance this with a suitable sense resistor, a couple of old audio wires and the free software package REW. More here: Impedance Measurement

I keep an old laptop around specifically for that duty, I don't want to risk blowing up the soundcard in my Audio PC. Of course a DATS would work too.

It isn't that hard to measure impedance this with a suitable sense resistor, a couple of old audio wires and the free software package REW. More here: Impedance Measurement

I keep an old laptop around specifically for that duty, I don't want to risk blowing up the soundcard in my Audio PC. Of course a DATS would work too.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- 3 way closed box damping materials