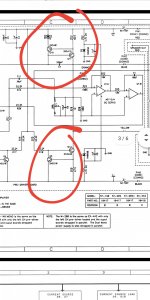

Im currently rebuilding a couple bkm200 monoblocks and i have recapped everything and got them in use at the moment but ive read a few post on here that these bjt metal case resistors did not have enough heatsinking in these amps. They do have the little stamped aluminum fin type that sit over top of them. My main question is i pick some new ones with the same bjt number will they be the same as far a specs go but just maybe bult better. They are thr voltage amplfing stage before the mosfets. These are motorola types and about 30 years old maybe 25. Any guidance would be appreciated. Ill post a pic of thr schematic.

Attachments

Your approach is kinda backwards. Thermal dissipation is given by operating current and voltage, which have been chosen by the amp designer. There's not much you can do about that.

You'll have to hunt for some TO-39 (TO-5 etc.) heatsinks and see whether they make anything better than what you already have. Those with some metalworking abilities may even want to DIY something (maybe find an old CPU heatsink or similar to saw apart and drill a TO-39-sized hole in the bottom).

You'll have to hunt for some TO-39 (TO-5 etc.) heatsinks and see whether they make anything better than what you already have. Those with some metalworking abilities may even want to DIY something (maybe find an old CPU heatsink or similar to saw apart and drill a TO-39-sized hole in the bottom).

I supposeis a possibility. I like the larger fins. ⋅-=≡ GoatGuy ✓ ≡=-⋅

Im just starting to learn this stuff. I dont have anyone to to teach me but ive been doing lots of reading. I know im proly backwards but im finaly to the point to where i atleast know enough to ask kinda the right questions. Trying to lean this stuff on your own is very difficult when you dont even know enough to word the question correct so i proly am doing this backwards but im not sure what forwards is lol sorry. I recapped this amp and im replacing the resistors with higher tolerance. A gentleman on here has posted on these bjt used in my amp and stated he has replaced quit a few because of not enough heatsinking. Im not trying to redesign the amp at this point. Im just trying to learn the circuts and how they work and how to match up the old parts with newer better qulaity parts. I guess my ma8n question is that are all bjt transistors either new or old with the same 2n part# do they have the same specs. Or to word it differently what specs of the bjt are most improtant to make sure thay matches up and which specs do not matter so much and will only help the life or performance of the bjt.

I'm just starting to learn this stuff.

I don't have anyone to to teach me but i've been doing lots of reading. (GG - good!)

I know I'm probably backwards but I'm finaly to the point to where I at least know enough to ask kinda-the-right-questions. (GG - good!)

Trying to lean this stuff on your own is very difficult when you don't even know enough to word the question correct so I probably am doing this backwards but I'm not sure what forwards is, LOL sorry. (GG - no problem!)

I recapped this amp and I'm replacing the resistors with higher tolerance. (GG - OK! just don't forget that higher accuracy components do not equate to "better sound". It is a hugely over-stated meme. Here's a great example: except when actually required, device precision is like a super-glossy polish on your car. Its pretty, but it doesn't make the car faster, or easier to steer, or quicker on the turns. )

A gentleman on here has posted on these BJT used in my amp and stated he has replaced quite a few because of not enough heatsinking. (GG - Which implies device-failures for that guy. But dig deeper: were there device failures, or again was his replacing them due to fear of failure?)

I'm not trying to redesign the amp at this point. (GG - good!)

I'm just trying to learn the circuts and how they work and how to match up the old parts with newer better qulaity parts. (GG - good, except when it breaks things! see below.)

I guess my main question is “do all BJT transistors (new or old) with the same 2nXXXX number have the same specs?” (GG - almost always, yes! But, there are so many Chinese Fakes, that you really need to be careful where they're sourced from. Not even Allied and Mouser are 100% safe, tho' they're way better than EBay and Amazon.)

Or to word it differently what specs of the BJT are most improtant to make sure thay matches up and which specs do not matter so much and will only help the life or performance of the BJT. (GG - all the specs!)

Good fellow — you're doing just fine, it seems to me. If I could gently offer one piece of advice, it would be “don't try to reëngineer an existing design” unless it is actually (while being used) showing signs of deficiency. Replacing a couple of little heat-sinks with ones that fit (of course), but that bigger fins, is not reëngineering. It is being prudent. And it is cheap. Do it.

But changing out transistors for others when you know what you're doing, is often frustrating: the replacements, the “better” devices are very often subtly different and result in a 'fix' that often doesn't 'fix' anything, and sometimes has unintended effects … like degrading a circuit board due to repeated desoldering-and-resoldering.

So, keep up the good work, and don't worry about how far up the learning curve you are. Time, practice, research, a good napkin and a pencil … they're the way you develop confidence, accuracy and competence.

⋅-⋅-⋅ Just saying, ⋅-⋅-⋅

⋅-=≡ GoatGuy ✓ ≡=-⋅

I like the paint reference lol. I actually build motors and carbs and do head work for a few circle track racers and i say the same thing when people spend 1000$ to wrap there dirt track cars with graphics. Lol i tell them spend 500$ on a set of isky tool room springs that will actually gain you something or spend 1000$ for a whole day in the dyno. Building high performance engines is a lot like building a high performance amp. Theres so many ways to do it and so many opions that your really better off to find somone thats good at it and follow there approach to the end. Of you try and take multiple peoples approaches to racing or amplifier circut technology you will end up worse then where you started it seams to me. Thats why i built my own flow bench and bought the stuff to do my own heads and all the rest. Now im into all this stuff i gotta start over with the tool list lol. Thanks for the help.

I like the paint reference lol.

I actually build motors and carbs and do head work for a few circle-track racers and I say the same thing when people spend 1000$ to wrap there dirt track cars with graphics. (GG - exactly!)

Lol I tell them spend 500$ on a set of ISKY tool-room springs that will actually gain you something or spend 1000$ for a whole day in the dyno. (GG - excellent advice!)

Building high performance engines is a lot like building a high performance amp. (GG - you bet!)

Theres so many ways to do it and so many opions that your really better off to find somone thats good at it and follow there approach to the end. (GG - you've got it!)

Of you try and take multiple peoples approaches to racing or amplifier circut technology you will end up worse then where you started it seams to me. (GG - yep!)

That's why I built my own flow bench and bought the stuff to do my own heads and all the rest. (GG - you the Man!)

Now I'm into all this stuff I gotta start over with the tool list lol. Thanks for the help.

Hey, thanks.

As I used to say, back in high school … with a remarkably strange uncle who actually had both a mill and a giant lathe in his garage (no space for a car!) who could make anything out of endless supplies of rod-and-block titanium… that titanium is our friend in making high-performance most-anything for racing.

Pistons, absolutely … especially when coupled with a titanium crankshaft and titanium piston rods. And just about every 'fast moving part'. Getting the inertia down is crucial. And aluminum — no matter what alloy or grade! — just doesn't cut it. Nowhere near durable enough.

The only real problem of titanium is that rubbing parts tend to suffer. It has a super-abrasive oxide coat, and until cylinders, pistons, rods, and the like are well glazed, they just tend to want to eat each other up.

Sigh… been there, done that.

⋅-=≡ GoatGuy ✓ ≡=-⋅

You haven't bothered to list which hemisphere you are in, so those $3.70 heat sinks might not cost you $6.80 each to ship from CZR.

But if you're in the western hemisphere, newark has nice TO5 heat sinks for $1.02 and TO-39 for $2.95. Measure the diameter of your cases and order appropriately. The smaller the number of deg C per watt, the better the heat flows. Shipping is about $8 to IN from SC.

You won't find any major house selling metal case transistors anymore. It is all TO202 or TO220, with the pins in a different order, bce instead of ebc. Sometimes when you twist them around they fall off after some years. Small houses that do ship metal case transistors usually leave most the specs off the data sheet. Vce sat, that all anyone needs to make a switch, right? Why would anybody use a transistor for linear amplification when we have class D? Just because everything modern has to be thrown away every 5 years, that keeps the garbage men employed, right?

But if you're in the western hemisphere, newark has nice TO5 heat sinks for $1.02 and TO-39 for $2.95. Measure the diameter of your cases and order appropriately. The smaller the number of deg C per watt, the better the heat flows. Shipping is about $8 to IN from SC.

You won't find any major house selling metal case transistors anymore. It is all TO202 or TO220, with the pins in a different order, bce instead of ebc. Sometimes when you twist them around they fall off after some years. Small houses that do ship metal case transistors usually leave most the specs off the data sheet. Vce sat, that all anyone needs to make a switch, right? Why would anybody use a transistor for linear amplification when we have class D? Just because everything modern has to be thrown away every 5 years, that keeps the garbage men employed, right?

Last edited:

Anyone who can machine titanium is skilled, its tricky stuff. Has a habit of welding itself to cutting tools and overheating (its a poor heat conductor as metallic elements go). Still its immune to corrosion and very tough and strong. But not something to make heatsinks from (!)

Incidentally bare metal heatsinks cannot radiate heat (i.e. far infra-red) effectively, painting, lacquering or anodizing will allow efficient heat radiation and thus improve their performance (which would be mainly convection if bare metal). Black anodizing on aluminium heatsinks is not (just) an aesthetic thing. (Thermal cameras are great for analyzing heat issues with electronics).

Incidentally bare metal heatsinks cannot radiate heat (i.e. far infra-red) effectively, painting, lacquering or anodizing will allow efficient heat radiation and thus improve their performance (which would be mainly convection if bare metal). Black anodizing on aluminium heatsinks is not (just) an aesthetic thing. (Thermal cameras are great for analyzing heat issues with electronics).

I think he was meaning how very hard it is to build internal engine parts from ti. Thats top fuel dragster stuff. Even they dont use ti for pistons cause the amount of serface prep and anti friction prep it takes and know how is very high tek stuff. Its rods crankshafts lifters stuff like that is somewhat common but for a person to build stuff like that without state of the art metalurgy knowledge is very difficult.

- Home

- Amplifiers

- Solid State

- 2n5416/2n3440 bjt transistors.