Almost finished building the second spiral. Even though the audible differences are small in comparison to the braced cabinet, the spiral does measure a bit better. I think the hump at 1.3K disappearing is due to the separation of the woofer chamber with the tweeter and crossover. Secondly i can pull the tweeter, turn it upside down and add a mid + tweeter on top while still having the woofer close to the mid for the 3-way experiment.

I finished the 2nd spiral and got me some fiberglass/glass wool 8cm thick on paper/aluminum backing which I removed prior to using it.

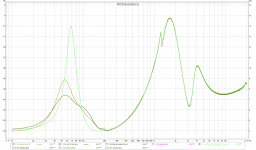

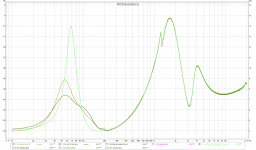

No fill comparison to no fill first spiral:

Looks close enough considering the difficulty of making these cabs identical.

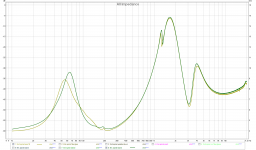

Different amounts of stuffing:

The first time I filled the second spiral with fiber glass I packed it a bit resulting in the huge shoulder at 100Hz. I remeasured the impedance with the enclosure upside down and at another location with the same results. Thinking I might have some weird resonance caused by not tightening the driver enough or something I removed and double checked everything and took out a bit of fiberglass resulting in the "less fill graph".

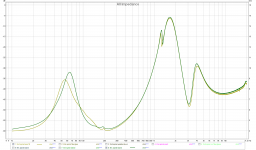

Comparison between first spiral with polyester mat filling and 2nd spiral with fiberglass filling:

I listened to these 2 extensively (mono signal and fast switching between the two spaced 20cm apart) and I have to say I can't really hear a difference.

I also noticed the little hump at 1.3K is still there, I'm still using the original wires so I haven't sealed the compartments with silicone, I'm hoping it goes away when I do. Otherwise I have no idea why it was gone with the first spiral.

@ wesayso: Did you find similar changes in impedance when stuffing with fiberglass or am i using too much (or too little)?

No fill comparison to no fill first spiral:

Looks close enough considering the difficulty of making these cabs identical.

Different amounts of stuffing:

The first time I filled the second spiral with fiber glass I packed it a bit resulting in the huge shoulder at 100Hz. I remeasured the impedance with the enclosure upside down and at another location with the same results. Thinking I might have some weird resonance caused by not tightening the driver enough or something I removed and double checked everything and took out a bit of fiberglass resulting in the "less fill graph".

Comparison between first spiral with polyester mat filling and 2nd spiral with fiberglass filling:

I listened to these 2 extensively (mono signal and fast switching between the two spaced 20cm apart) and I have to say I can't really hear a difference.

I also noticed the little hump at 1.3K is still there, I'm still using the original wires so I haven't sealed the compartments with silicone, I'm hoping it goes away when I do. Otherwise I have no idea why it was gone with the first spiral.

@ wesayso: Did you find similar changes in impedance when stuffing with fiberglass or am i using too much (or too little)?

Last edited:

Interesting, ever finalize your conclusions? Really nice controlled testing [emoji1360]

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I'm using them as a bedroom system now, still sounding good 🙂.

As far as the polyester vs fibreglass, I think you can get equal results with both in this type of enclosure. The pathlength is so long that it makes up for the lesser damping from the polyester. In more traditional boxes I only use fibreglass and felt for damping at the moment. Polyestermat (or sometimes felt) is only used as a barrier/filter to protect the drivers from the glass fibres and to have some better impedance matching.

Don't use fibreglass for vented enclosures if you like your lungs, I don't like vents but I would use very densely packed polyester. (IKEA pillows are a very cheap source of polyfill and it is better then the polyestermat filter stuff I used for the monitor audios) Real sheep wool is comparable to fibreglass in terms of damping but silly expensive if you want to use it for large (>30L) enclosures.

As far as the polyester vs fibreglass, I think you can get equal results with both in this type of enclosure. The pathlength is so long that it makes up for the lesser damping from the polyester. In more traditional boxes I only use fibreglass and felt for damping at the moment. Polyestermat (or sometimes felt) is only used as a barrier/filter to protect the drivers from the glass fibres and to have some better impedance matching.

Don't use fibreglass for vented enclosures if you like your lungs, I don't like vents but I would use very densely packed polyester. (IKEA pillows are a very cheap source of polyfill and it is better then the polyestermat filter stuff I used for the monitor audios) Real sheep wool is comparable to fibreglass in terms of damping but silly expensive if you want to use it for large (>30L) enclosures.

Sonic Barrier is what Selah Audio uses, I've tried it, it seems pretty good without disturbing the cabinet volume. I'd try the smaller mult-layer materials to get rid of any noticable cabinet vibrations.

By the way, that's not a secret, Selah posted this in a Parts Express forum. I am not revealing anything that wasn't already public domain. 😀

Best,

Erik

By the way, that's not a secret, Selah posted this in a Parts Express forum. I am not revealing anything that wasn't already public domain. 😀

Best,

Erik

Last edited:

I have started about two months ago with my own speaker build DIY project.

I am using a set of Boston Acoustic VR1 speakers. I removed the drivers, ports, XO's and stuffing. The arrangement of the VR1 is TMM. My speaker build is a MTM arrangement and I do not know what to expect. I will use the exact same drivers and crossovers for the new cabinets.

It has taken me an afternoon to cut all the 22mm MDF panels, but now over six weeks to build a router jig to cut perfect circles. Every circle is either to big or two small by 1mm or 0.5mm....it is the most frustrating thing as I expected to take 5 days to build these new enclosures. I have given up many times, but the VR1's are completely cut up and I just must finish it.

I really like this thread, because it has inspired me again to continue with the project....

I am using a set of Boston Acoustic VR1 speakers. I removed the drivers, ports, XO's and stuffing. The arrangement of the VR1 is TMM. My speaker build is a MTM arrangement and I do not know what to expect. I will use the exact same drivers and crossovers for the new cabinets.

It has taken me an afternoon to cut all the 22mm MDF panels, but now over six weeks to build a router jig to cut perfect circles. Every circle is either to big or two small by 1mm or 0.5mm....it is the most frustrating thing as I expected to take 5 days to build these new enclosures. I have given up many times, but the VR1's are completely cut up and I just must finish it.

I really like this thread, because it has inspired me again to continue with the project....

I have started about two months ago with my own speaker build DIY project.

I am using a set of Boston Acoustic VR1 speakers. I removed the drivers, ports, XO's and stuffing. The arrangement of the VR1 is TMM. My speaker build is a MTM arrangement and I do not know what to expect. I will use the exact same drivers and crossovers for the new cabinets.

It has taken me an afternoon to cut all the 22mm MDF panels, but now over six weeks to build a router jig to cut perfect circles. Every circle is either to big or two small by 1mm or 0.5mm....it is the most frustrating thing as I expected to take 5 days to build these new enclosures. I have given up many times, but the VR1's are completely cut up and I just must finish it.

I really like this thread, because it has inspired me again to continue with the project....

Don't give up! This is my first time with a router and a hole cutting jug too. I bought a commercial hole jig and it works very well. The trick is to have a backing sacrificial board that is screwed to the baffle being cut.

http://www.diyaudio.com/forums/multi-way/297171-rs28f-rs180p-b80-hole-filler-3-way.html

For some reason I didn't get any notifications about new posts to this thread. Is there a maximum number of subscriptions?

So

@ Xrk: Thanks 🙂

@ Stollas: Just take your time and although it might sound cheesy, the voyage is a lot more interesting then the destination.

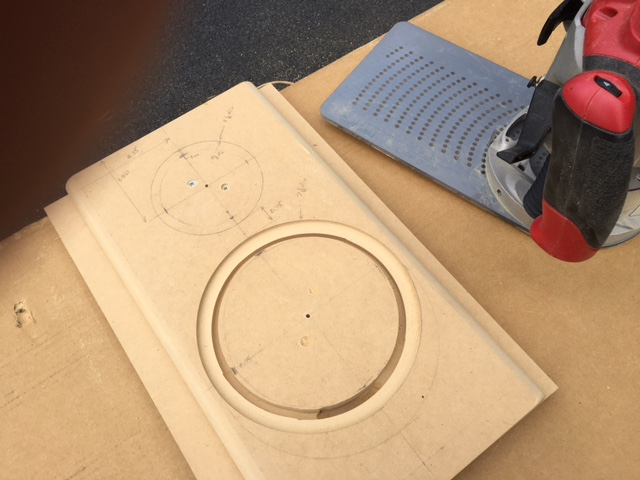

Some pics of my homemade circle jig made from leftover pieces of Birch ply using the router and a saw:

So

@ Xrk: Thanks 🙂

@ Stollas: Just take your time and although it might sound cheesy, the voyage is a lot more interesting then the destination.

Some pics of my homemade circle jig made from leftover pieces of Birch ply using the router and a saw:

Zonneschimmel, thank you soo much!For some reason I didn't get any notifications about new posts to this thread. Is there a maximum number of subscriptions?

So

@ Xrk: Thanks 🙂

@ Stollas: Just take your time and although it might sound cheesy, the voyage is a lot more interesting then the destination.

Some pics of my homemade circle jig made from leftover pieces of Birch ply using the router and a saw:

View attachment 575451

View attachment 575452

I am in Slovakia at the moment and I will post a pic of the jig I made....I will stay patient and jus try to get it right....

Thank you so much!

Thank you very much for sharing your experimentation. You save me a lot of time and your result confirm my thoughts.

After 3 years, I am back!I have started about two months ago with my own speaker build DIY project.

I am using a set of Boston Acoustic VR1 speakers. I removed the drivers, ports, XO's and stuffing. The arrangement of the VR1 is TMM. My speaker build is a MTM arrangement and I do not know what to expect. I will use the exact same drivers and crossovers for the new cabinets.

It has taken me an afternoon to cut all the 22mm MDF panels, but now over six weeks to build a router jig to cut perfect circles. Every circle is either to big or two small by 1mm or 0.5mm....it is the most frustrating thing as I expected to take 5 days to build these new enclosures. I have given up many times, but the VR1's are completely cut up and I just must finish it.

I really like this thread, because it has inspired me again to continue with the project....

Project stalled...in the meantime, I remodelled my house and built a new garage to carry out my hobbies...

In July 2017, I bought the Jasper jig and a new router....they came out of the box last week for the first time...

After making many mistakes and destroying one MDF board after another in 2016, with the Jasper, life was much easier...I have made good progress...I have been able to seat these odd-shaped tweeters....the woofers also fit perfectly...

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- 2 new cabinets for monitor audio silver s2 - test