I'm well on my way on completing my DIY turntable. I love the way the Teres turntable looked, so it's modeled (well, really copied) in my design.

The bearing was actually the easiest problem I had in this project. I wound up using the Shovel Head bearing method used in the Altmann turntable. It is definitely sufficient to hold the 22lb platter.

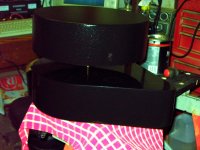

The whole deal is made form 3/4" MDF cut with a basic jigsaw and then stacked and glued with regular wood glue. The edges were then sanded flat and even. The paint job has taken the most time. I've been working on it and experimenting with what I was going to be able to do to make it look the best. I had a gallon of SW gloss black latex paint. This turned out to be the winner as I was able to attain a high gloss finish. It's dang near piano black. I am more than happy with the way the finish has turned out on the pieces that have been completed.

The design consists of the traditional Teres design with a sub plinth that will hold the turntable and the motor. The plinth will sit on rubber feet to offer some amount of decoupling from the motor which will also be isolated with rubber feet.

I need to complete the finish on the platter and the edges of the sub plinth. The tonearm will be a Ladegaard air bearing type that I have almost completed as well. The motor will be one from a floppy drive. Not sure what kind of enclosure the motor will be in, but I'll tackle that when I get to it.

I've included a couple of obligatory pictures. Any comments or suggestions are welcome. It will hopefully be finished in the next couple of weeks. I can't wait!!!

The bearing was actually the easiest problem I had in this project. I wound up using the Shovel Head bearing method used in the Altmann turntable. It is definitely sufficient to hold the 22lb platter.

The whole deal is made form 3/4" MDF cut with a basic jigsaw and then stacked and glued with regular wood glue. The edges were then sanded flat and even. The paint job has taken the most time. I've been working on it and experimenting with what I was going to be able to do to make it look the best. I had a gallon of SW gloss black latex paint. This turned out to be the winner as I was able to attain a high gloss finish. It's dang near piano black. I am more than happy with the way the finish has turned out on the pieces that have been completed.

The design consists of the traditional Teres design with a sub plinth that will hold the turntable and the motor. The plinth will sit on rubber feet to offer some amount of decoupling from the motor which will also be isolated with rubber feet.

I need to complete the finish on the platter and the edges of the sub plinth. The tonearm will be a Ladegaard air bearing type that I have almost completed as well. The motor will be one from a floppy drive. Not sure what kind of enclosure the motor will be in, but I'll tackle that when I get to it.

I've included a couple of obligatory pictures. Any comments or suggestions are welcome. It will hopefully be finished in the next couple of weeks. I can't wait!!!

Attachments

Thanks, just took a break from sanding the platter to browse the forum. I truely love this place. I have learned so much from it and I'll try my best to contribue all that I can back to it. If this thread can help just 1 person, then I feel it would have been worth it. Thanks again for the kind words.

I am also in the beginning stages of my DIY table and your's looks great!

Any updates since the last post?

Any updates since the last post?

Painting Process

Would you share the painting process that you used and how you filled in the edges of the MDF? I have wanted to try this material as well but I haven't a good process to fill the edges of the boards.

Rick Kernell

Would you share the painting process that you used and how you filled in the edges of the MDF? I have wanted to try this material as well but I haven't a good process to fill the edges of the boards.

Rick Kernell

Any updates on this project? How did you get the platter round and concentric to the valve shaft? I am in the process of a turntable project and with limited tools am finding kinda tough going. Yours looks great so far.

Last edited:

Hey Stan,

I've been all over the place with projects. Blame it on my ADD and the perfectionist in me, and sadly in this case my Dad who burned the particular piece in the photos as he mistakenly thought it was scrap wood. Granted it didn't look like it did in the photos, the paint was completely removed to try other finishing methods.

Right now I'm taking a wood working class locally and the great thing is that once the class is completed, I have access to the workspace for my own projects. The shop has a lathe and I will use this to get a perfectly round platter. It seems to be the only way I can think of to get a perfect result, and it has to be as perfect as possible.

Let me know if you have any specific questions and I'll do my best to answer them. Good luck on your project.

Joe

I've been all over the place with projects. Blame it on my ADD and the perfectionist in me, and sadly in this case my Dad who burned the particular piece in the photos as he mistakenly thought it was scrap wood. Granted it didn't look like it did in the photos, the paint was completely removed to try other finishing methods.

Right now I'm taking a wood working class locally and the great thing is that once the class is completed, I have access to the workspace for my own projects. The shop has a lathe and I will use this to get a perfectly round platter. It seems to be the only way I can think of to get a perfect result, and it has to be as perfect as possible.

Let me know if you have any specific questions and I'll do my best to answer them. Good luck on your project.

Joe

stanbp, very nice

This table looks quite good so far. Not to my aesthetic taste, but nice none-the-less.nice adjustable arm board.

This table looks quite good so far. Not to my aesthetic taste, but nice none-the-less.nice adjustable arm board.

This is great, guys. I always wanted to build my own turntable but never made the jump. Maybe this will give me the extra push needed.

Kenneth

Kenneth

Thanks guys.....since this pic I have actually made another base for the TT. Same basic shape but it is 2 pcs of 3/4 mdf sandwiched between 2 pcs of birch ply. This project is kinda a test run to see if I can actually end up with a nice sounding table on a budget. Later on I may try another with different/better materials. I don't know very much about TT's so this is a learning experience. Heck, I only own a few albums

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- 1st attempt at a DIY turntable