Hi, im having a go at building a dc-dc converter, that will take 12v and output +55v, 0v and -55v.

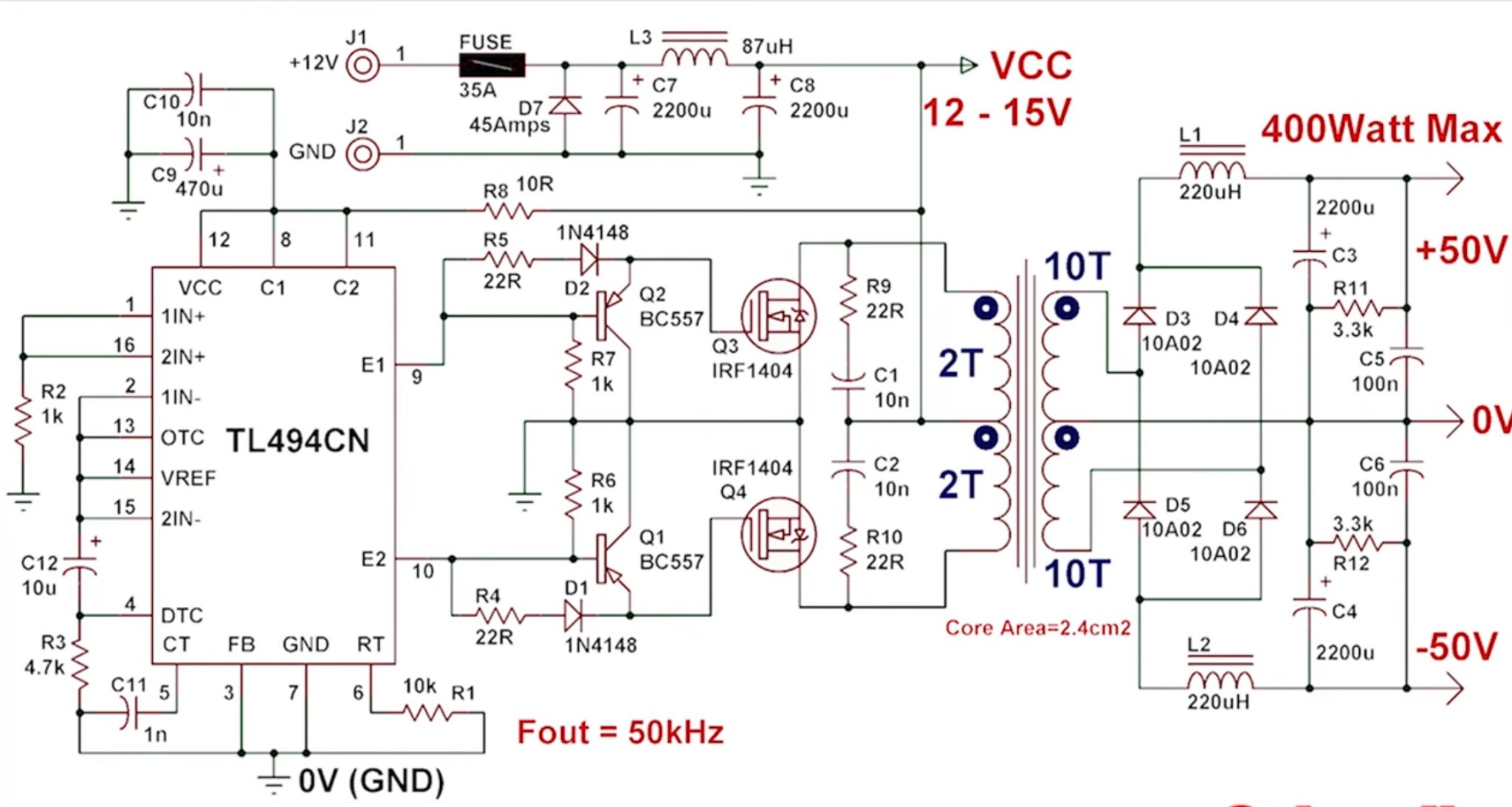

This is the circuit i am using, with a hand wound toroid transformer:

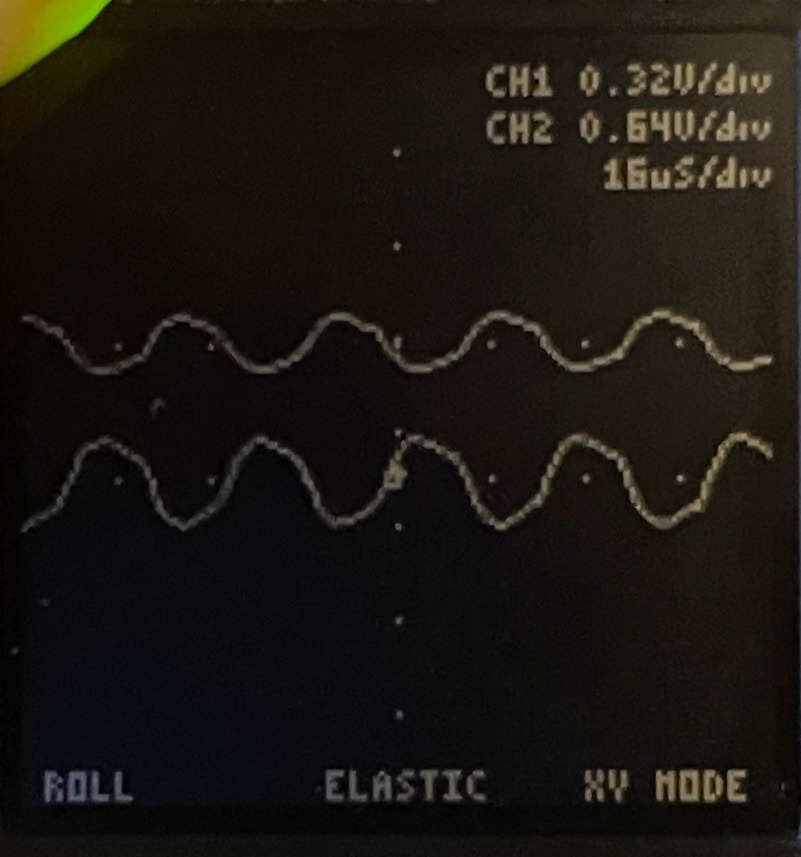

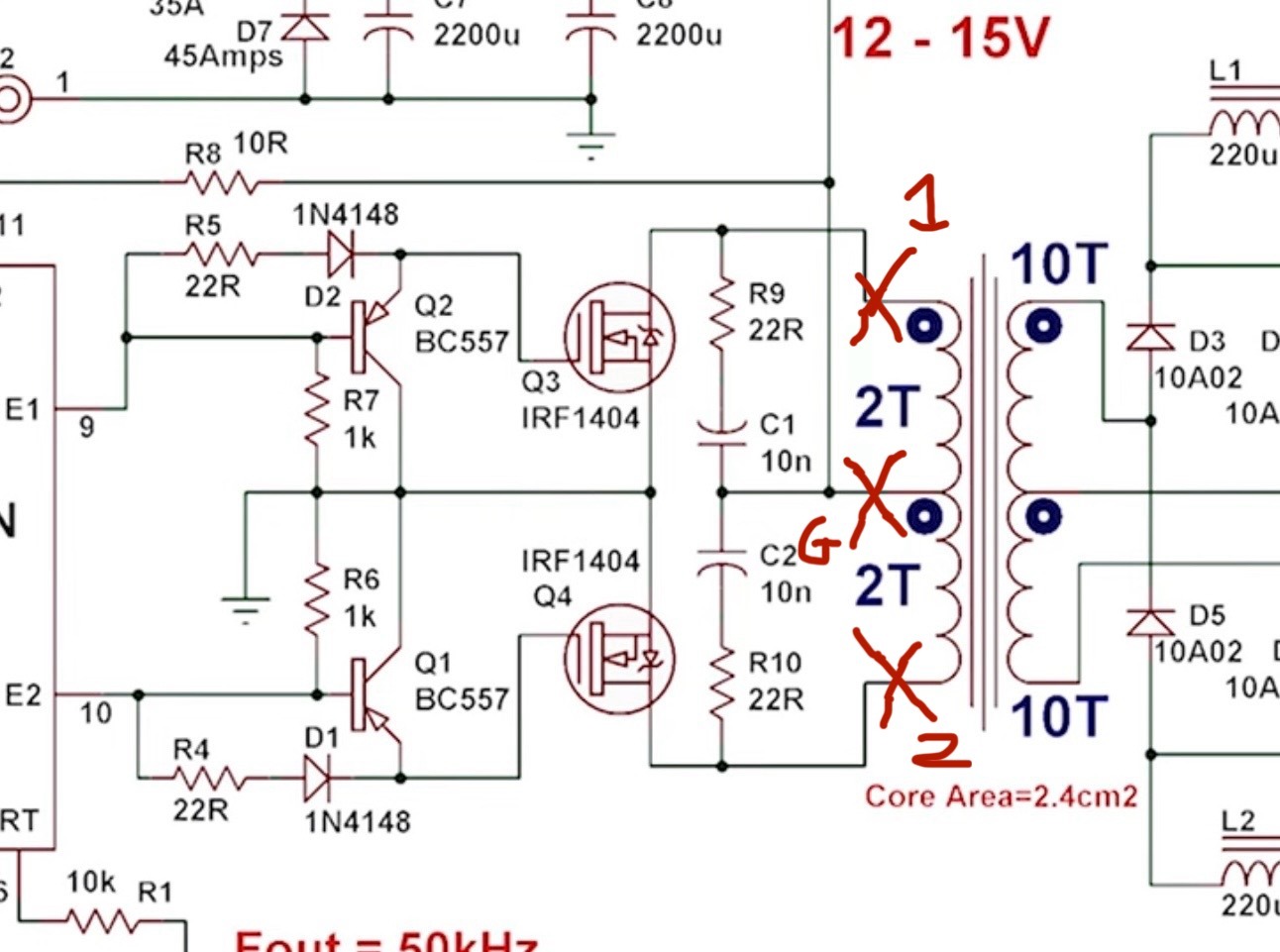

Unfortunately, im not reading any voltage on the 50-0-50 outputs, however using a basic oscilloscope with channel 1 attached to point 1, and channel 2 attached to point 2, with oscilloscope ground to point G, i believe that the oscillation side of the circuit is working ok (this reading was taken without the transformer attached, so just testing the oscillating circuit)

Im not quite sure why channel 1 is not swinging as much as channel 2. Both read as having a frequency of 35khz.

I may have wound my transformer wrong, anyone know how to wind a transformer like this? I doubt i can purchase a specific one for this.

Any ideas appreciated, better circuits etc.

This is the circuit i am using, with a hand wound toroid transformer:

Unfortunately, im not reading any voltage on the 50-0-50 outputs, however using a basic oscilloscope with channel 1 attached to point 1, and channel 2 attached to point 2, with oscilloscope ground to point G, i believe that the oscillation side of the circuit is working ok (this reading was taken without the transformer attached, so just testing the oscillating circuit)

Im not quite sure why channel 1 is not swinging as much as channel 2. Both read as having a frequency of 35khz.

I may have wound my transformer wrong, anyone know how to wind a transformer like this? I doubt i can purchase a specific one for this.

Any ideas appreciated, better circuits etc.

My first recommendation would be to use an ee , efd, ei, or another core and bobbin kit to wind the transformer. Way easier with no real loss in performance.

The drains of your fet primary drivers have no path to pull them high in your test circuit. Add a couple of resistors for the test without the xfmr. Be careful with the power dissipation. Resistance value not critical. 50 ohms or so will help you see what’s going on.

The drains of your fet primary drivers have no path to pull them high in your test circuit. Add a couple of resistors for the test without the xfmr. Be careful with the power dissipation. Resistance value not critical. 50 ohms or so will help you see what’s going on.

Looking closer, your turns ratio is too large. Say the output voltage without losses is 60 volts, and the input voltage is 12 volts. That would mean the turns ratio should be 5.

Thanks for the replies, ill definitely add a pullup resistor onto the fet drain.

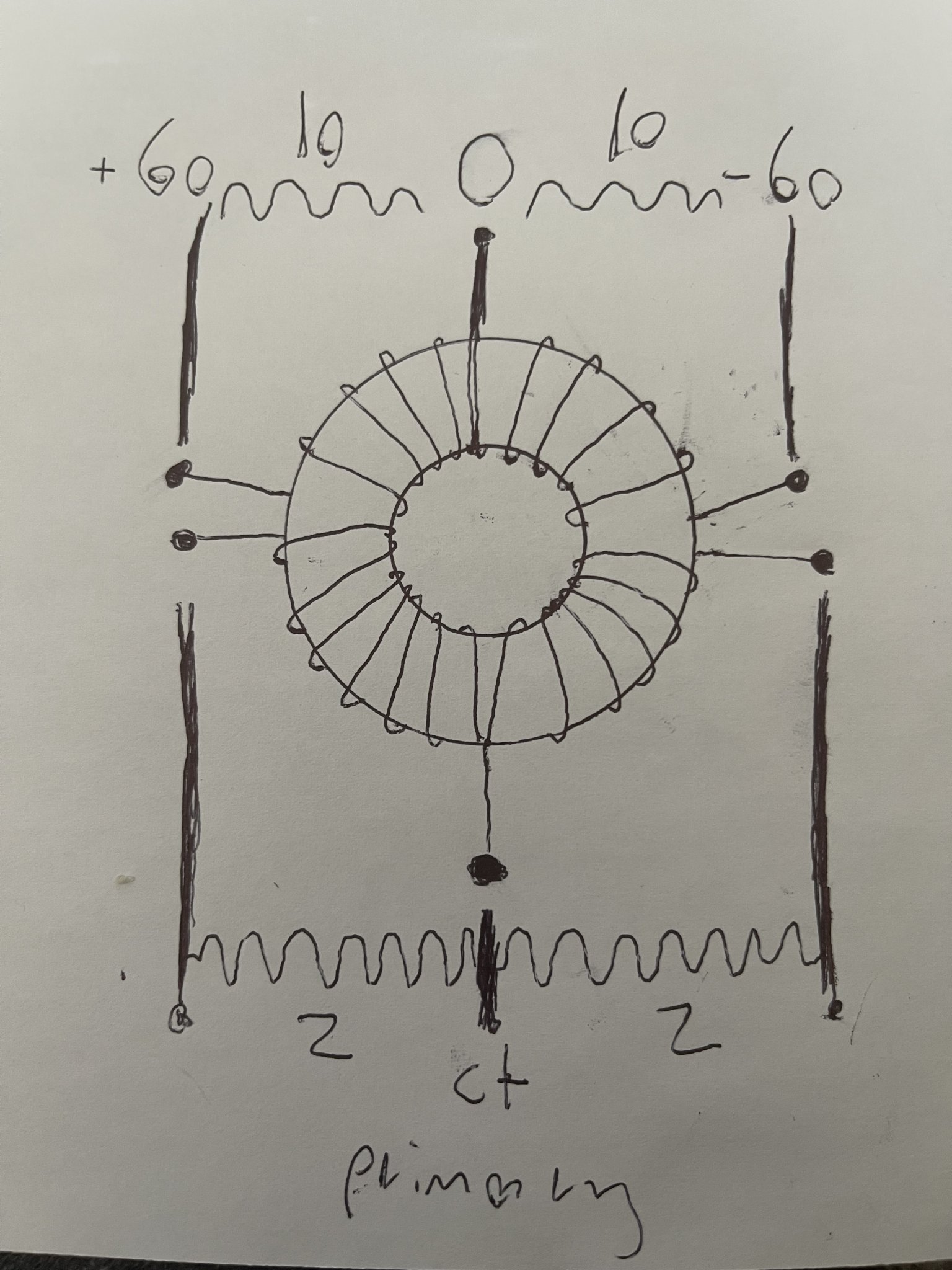

Roughly speaking, i was going to wind my transformer like this (ignore the number of turns drawn onto the core) with the primary side taking up half the core, and the secondary taking up the other half. I have also seen some designs where the primary and secondary run alongside each over, covering the whole core.

If i should wind it like this, i assume that i would have to use multiple strands of wire with their ends soldered together, to make 4 turns take up half the core.

Roughly speaking, i was going to wind my transformer like this (ignore the number of turns drawn onto the core) with the primary side taking up half the core, and the secondary taking up the other half. I have also seen some designs where the primary and secondary run alongside each over, covering the whole core.

If i should wind it like this, i assume that i would have to use multiple strands of wire with their ends soldered together, to make 4 turns take up half the core.

The winding on both the primary and secondary are wrong assuming the winding is as drawn. As drawn, the winding direction reverses as it traverses across the center tap. The windings for both the primary and secondary should start and finish without a reversal as it crosses the center tap.

Think of it as one continuous winding with a loose loop where the center tap occurs.

With that change the transformer should be functional. Get to that point first.

There are several winding techniques that can improve the efficiency of the transformer if you are not satisfied with performance. Get it to work first, and we can explore those techniques when needed.

The wiring of the transformer on the schematic is correct along with the polarity dots.

Think of it as one continuous winding with a loose loop where the center tap occurs.

With that change the transformer should be functional. Get to that point first.

There are several winding techniques that can improve the efficiency of the transformer if you are not satisfied with performance. Get it to work first, and we can explore those techniques when needed.

The wiring of the transformer on the schematic is correct along with the polarity dots.

Thank you, ill make sure to wind on the same direction throughout the primary this time.

One other thing, im still struggling to make 2 turns, centre tap, then another 2 turns, take up half the core. Should i use wire made up of multiple strands of copper, so its wider?

One other thing, im still struggling to make 2 turns, centre tap, then another 2 turns, take up half the core. Should i use wire made up of multiple strands of copper, so its wider?

You can use multiple strands of smaller gauge wire and connect them in parallel. Litz wire is made up of many strands woven and insulated from each other. Litz is ideal for high frequency transformers like this. It is preferred because a single fat wire suffers from skin effect. At higher frequencies, current only flows on the surface of conductors due to skin effect. Skin thickness is a function of frequency. Any configuration of multiple strands in parallel needs to have the strands insulated from one another ( until the terminations ) to reduce skin effect. The strands should be no thicker than twice the calculated skin thickness.

- Home

- Design & Build

- Electronic Design

- 12v to dual rail converter