Are you running the filaments at 200mA or 250mA? Some 01a are microphonic, but generally they are ok. With the mechanical arrangement you have you're better than me!. Mine is dead quiet though and no hum. There is no need for any screening on the valves. Have you tried moving the preamp? Also you will need to check your wiring.

Is that fan on the left working?

Is that fan on the left working?

Yes - with these old tubes like 26 and 01A we're going back to the 1920s and 1930s. They will be variable in quality and performance - some are more microphonic than others so that will always be a potential variable. Hence it's useful to have a small stock to choose from.

Then there's starving the filaments as Ale says, and also using a massive chassis with optional damping and suspension. Like a lot of things we works with, the fault could be in any number of areas so you try to cover them all in the design stage. Doesn't always work out in practice! Then if you fix it you learn something new to add to the mix.

Then there's starving the filaments as Ale says, and also using a massive chassis with optional damping and suspension. Like a lot of things we works with, the fault could be in any number of areas so you try to cover them all in the design stage. Doesn't always work out in practice! Then if you fix it you learn something new to add to the mix.

The filaments are at 200mA, 3.4V. 115V anode. The screening works on the 26s, so I just applied it here, but it removes in a few seconds. And yes, the fan is running; it's at about 5V DC and didn't cause problems with the 26s, but I'll look at that too.

Unfortunately moving the preamp is not really practical, it's as far from the PSU as I can get it in my rack. Rotating it slightly is possible short term though, and I could pull the PSU out onto the floor. I will start with shorting the inputs, and then move on to screening the signal wiring if needed, but first I will try the other pair of 01As.

It's disappointing, as the cello music I played last night sounded better than I have heard it, although that might be euphonic colouration. But I don't care, as long as it's consistent! Into The Trees | Zoe Keating

Unfortunately moving the preamp is not really practical, it's as far from the PSU as I can get it in my rack. Rotating it slightly is possible short term though, and I could pull the PSU out onto the floor. I will start with shorting the inputs, and then move on to screening the signal wiring if needed, but first I will try the other pair of 01As.

It's disappointing, as the cello music I played last night sounded better than I have heard it, although that might be euphonic colouration. But I don't care, as long as it's consistent! Into The Trees | Zoe Keating

I'm sure you know this, but you need to keep filament chokes well away from any active signal circuits and the tubes themselves. The same can apply to HT chokes, though there's very little current in this case. I'm not sure how much you're talking hum and how much microphonics here.

Ok. Try turning the fan off, no need to force ventilation on this preamp unless you're using it for anything else

Have you changed the wiring?

It looked like you had a very neat layout so am surprised that your getting some noise

I will try another pair of valves as Andy suggested

No colouration, just the 01a is very detailed!

Have you changed the wiring?

It looked like you had a very neat layout so am surprised that your getting some noise

I will try another pair of valves as Andy suggested

No colouration, just the 01a is very detailed!

The 190mH common mode chokes for the filament supply are in the PSU case, a couple of feet away from the signal wiring.I'm sure you know this, but you need to keep filament chokes well away from any active signal circuits and the tubes themselves. The same can apply to HT chokes, though there's very little current in this case. I'm not sure how much you're talking hum and how much microphonics here.

And the last pair of HT chokes are in the back corners of the pre-amp chassis. The signal and gyrator to anode wiring are those white (silver in Teflon) wires you can see here. Unscreened at the moment, the same as the 26. The only real difference from that is gyrator instead of transformer. Oh, and 01A valves. 😀

An externally hosted image should be here but it was not working when we last tested it.

How much hum and microphonics? I can hear the hum sat across the room, and if I tap the chassis the clang takes several seconds to die away. Tapping a valve is very loud!

Last edited:

I turned off the fans, no change. Removed the mesh and got a horrible howl from the left channel! Changed both valves and replaced the mesh and Sorbothane, back to original hum and microphonics. Flicked the ground lift switch from 20 ohms, to direct, to complete lift, no appreciable change. But when I removed the leads connecting the steel sheet above the amp and especially the copper foiled shelf underneath, from the earthing post on the top plate, the hum increased. The bottom of the chassis is open, so I will have a look for some aly or steel perforated sheet and fit a grounded base plate. After that, I suppose it will be screening the signal wiring. And trying the TVC on the output as a volume control; that quietened the 26 more when I tried it, but the TKD pot on the input sounded better, so I went back to that.

Hmm, I suspect some ground loop issue or induced noise from the chokes.

My wiring isn't as neat as yours, I have no shielding anywhere and yet is dead quiet

My first 01a was an open frame and my current VT-25 is mounted on a piece of wood

I'd review your ground connections as well as every earth point you have on each plate etc

My wiring isn't as neat as yours, I have no shielding anywhere and yet is dead quiet

My first 01a was an open frame and my current VT-25 is mounted on a piece of wood

I'd review your ground connections as well as every earth point you have on each plate etc

Ok, I'll put that on the list too! But it's curious, the position of the components, apart from the gyrators and rotating the Coleman regs, is exactly the same as the 26. But as you say, grounding could be the key. But the microphony makes the 26s seem rock solid!

It may take a while before I manage to work through it all. So many other things have been left undone while I was ill, so I'll have to work through those too!

It may take a while before I manage to work through it all. So many other things have been left undone while I was ill, so I'll have to work through those too!

Before doing any surgery, I´d try changing the valves. You may just be unlucky and have a bad pair. Some could be really microphonic and also more susceptible to pick up hum.

I bought 4 from the same supplier, and I have already swapped them. No difference. I will try all the possible solutions, but if they don't work I would like to post them to someone to try in their own amp, before buying more.

Last edited:

baloon tubes must ring, it´s their construction.

I thought it was also very much a question of how robust the filaments are. Tubes with filament currents of less than 250mA are a lot more microphonic than those with higher currents. Those with 50-60mA filaments like 1G4 and 30 can be very microphonic and hard to control with small signals. I haven't had problems with 01A, though.

Right then, I've put the Sowter TVC on the output, and turned the 01A's volume control pot all the way up, so it just acts as 100k loading across the inputs. And the hum has gone, at least at sensible listening levels, and the microphony is down to a minimal level. Unfortunately the TVC came wired up and the lowest volume level is nowhere near mute. But liveable with for now. I will still try all the quieting methods suggested though, especially grounding. And I may try the TVC as an AVC, just using the secondary.

Last edited:

Using TVC (as primary-secondary transformer) is the best method for killing "ground loop" hum, especially not grounding secondary.

Using it as AVC, the ground loop is remains.

Using it as AVC, the ground loop is remains.

Someone over on the Wigwam mentioned this, gyrators acting as RF generators. Is this relevant, or even true? DIY Audio Projects Forum • 300b preamp

No, I think they have misinterpreted that the resulting hybrid mu-follower stage (i.e. gyrator load) has very high bandwidth. If layout is poor and/or the right measures are taken (e.g. grid/screen stoppers) it can oscillate when unstable. With the 4P1L this can be done easily on the bench by placing the voltmeter probes in the anode. If you add ferrite beads/stoppers then there is no problem.

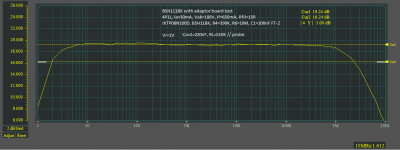

Have a look at the frequency response in the attached. Loading it with 100k just impacts the LF response, not the HF.

Have a look at the frequency response in the attached. Loading it with 100k just impacts the LF response, not the HF.

Attachments

Someone over on the Wigwam mentioned this, gyrators acting as RF generators. Is this relevant, or even true? DIY Audio Projects Forum • 300b preamp

i used for ixys 1kv fet for supply test as ccs, at some point is oscillated

- Home

- Amplifiers

- Tubes / Valves

- 01A question