Can anyone recommend a semi-permanent "loctite" for nylon standoff, nuts, etc....similar to a thread locker

Thanks

Thanks

they are holding tiny rectifier bridge pcbs that i got from parts connection, only one hole with three other standoffs to hold the corners in place.....I was hoping to lock the black standoff in place as it is two pieces i guess i could use a metal lock washer

Why do you need the 3 other standoffs? doesn't look like more support is needed - or is this in a high vibration environment (powered subwoofer for instance?). Why would thread-lock help anyway? An anti-shake washer is normally all that's needed.

Hey Russ, Thanks captain obvious your so much help. I did not wire it point to point as that what it was wired before...didnt like it and it shorted out as a wire went into no mans land

Am I the only one who finds it disappointing that Parts Connection would make a PCB available that doesn't have mounting holes? That's pretty lame.

Tom

Tom

No you're not. 🙂Am I the only one who finds it disappointing that Parts Connection would make a PCB available that doesn't have mounting holes?

jeff

Yea, i wasnt happy when i got them but cheap and i made do. Good thing now is Prts Connection is having a 25% off now until Sept

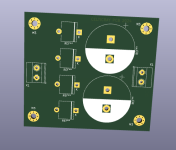

Drawing those in KiCAD is a 15 minute max job.

A boardhouse can make the boards in the color you want, with M3 mounting holes (PCBs should have them, period) for real safety, with industry standard 5.08 mm connectors, your own name on them being the Kanye West in PCB design and they will probably be cheaper too.

If you are hardcore you could add footprints for the caps too and you’ll have a nice smaller and more sturdy solution.

What voltages and currents do you need? I may have a simple design.

A boardhouse can make the boards in the color you want, with M3 mounting holes (PCBs should have them, period) for real safety, with industry standard 5.08 mm connectors, your own name on them being the Kanye West in PCB design and they will probably be cheaper too.

If you are hardcore you could add footprints for the caps too and you’ll have a nice smaller and more sturdy solution.

What voltages and currents do you need? I may have a simple design.

Last edited:

This stuff is pretty good.

Goop

https://www.amazon.com/Amazing-GOOP-170011-Marine-Adhesive/dp/B000BQUI7S/

I use it for everything now, its waterproof, can flex and you can somewhat remove it if need be.

Should work great for your situation.

Goop

https://www.amazon.com/Amazing-GOOP-170011-Marine-Adhesive/dp/B000BQUI7S/

I use it for everything now, its waterproof, can flex and you can somewhat remove it if need be.

Should work great for your situation.

How about using lock washers?Can anyone recommend a semi-permanent "loctite" for nylon standoff, nuts, etc....similar to a thread locker

Thanks

A construction tip is to do things both mechanically and electrically safe. Looks often pleasing too. My own demand is that stuff should be able to fall from a table and still works OK.

Just a simply tryout with (too large) 25 mm caps but they are real Celticray® boards. Of course it can be made symmetric/dual voltage.

Just a simply tryout with (too large) 25 mm caps but they are real Celticray® boards. Of course it can be made symmetric/dual voltage.

Attachments

Last edited:

I think I would try a little hot glue or even a small dab of epoxy. If removal is needed breaking the seal should be easy enough.

Also, a search turned up these:

https://www.vibra-tite.com/threadlockers/plastic-compatible/vibra-tite-325-plastic-threadlocker/

https://www.fleetequipmentmag.com/p...as been,and hold plastic fasteners together.”

Also, a search turned up these:

https://www.vibra-tite.com/threadlockers/plastic-compatible/vibra-tite-325-plastic-threadlocker/

https://www.fleetequipmentmag.com/p...as been,and hold plastic fasteners together.”

It just seems so $1.95, when you could do it properly to start with.I think I would try a little hot glue or even a small dab of epoxy.

jeff

I tried to learn to design a simple cap mounting board and became frustrated trying to learn about layers and traces vs ground planes and board thickness. Then how to order the holes through plated etc. What you guys think is so easy is not for a novice. I can manage to order boards designed by someone else but you guys are fooling yourselves if you think designing that board is anything but challenging. Looking for an nylon adhesive is not looking for a cludge IMO.

It looks like it's intended to be soldered to a second PCB using pins through the 4 holes on the side. Probably to replace a SIP full bridge rectifier. Mounting holes wouldn't be needed in that situation.Am I the only one who finds it disappointing that Parts Connection would make a PCB available that doesn't have mounting holes? That's pretty lame.

Tom

- Home

- Design & Build

- Construction Tips

- Nylon standoffs