G'day Guys,

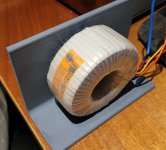

I am intending to use some 125x75 mild steel angle as a bracket to mount a Toroidal transformer on its side.

My local supplier has 6mm, 8mm, 10mm and 12mm thickness available.

12mm seems a bit silly. Its only a 300VA transformer.

Is 6mm going to be rigid enough?

10mm also silly?

8mm a happy medium?

Just go with the 6mm?

I am intending to use some 125x75 mild steel angle as a bracket to mount a Toroidal transformer on its side.

My local supplier has 6mm, 8mm, 10mm and 12mm thickness available.

12mm seems a bit silly. Its only a 300VA transformer.

Is 6mm going to be rigid enough?

10mm also silly?

8mm a happy medium?

Just go with the 6mm?

I have some premade steel brackets and I think those are 1.5-2mm and that seems plenty for "normal" usage scenarios. 6mm should be more than enough.

125 x 75 even if 6mm thick would suport a person, (or a small car). Something like 40 x 40 x 3 would be more than enough. Many times transformers are just bolted to the chassis base which is normally 1.2mm to 1.5mm thick. Could you post a picture of the chassis showing detail?

I have used Simpson Strong-Tie angles from the hardware store and they are 18 gauge which is 1.2mm. Plenty strong.

Just to point out a 25% increase in thickness means 100% increase in stiffness, its a cube law, so going from 1.2mm to 6mm is crazy overkill, 125 times stiffer... 6mm steel is for heavy truck chassis construction! Going to 2mm from 1.2mm is a world of difference already.

You also need to consider that when the toroid transformer is clamped to the bracket, it forms a composite beam. The effective thickness becomes more than that of the steel plate itself. The supporting structure is no longer a simple plate.

But the rubber gasket is something like 100 to 300 times more compliant than the steel so its effect is down in the noise for stiffness calculations.

The load will transfer to the stiffest component, so gasket goes out of play very quickly. The effective cantilever distance will shorten from the centre of the toroid to somewhere in the middle of the core so the bending moment is greatly reduced.

I was mistaken about the Simpson Strong-Tie angles that I have used for toroid mounts. They are 12 gauge, not 16 gauge, so they are just over 2 mm thick. Available at Home Depot and they are easily drilled to customize for your application. They are plenty rigid.

Attachments

Thanks for the engineering lesson Guys. It's always nice to learn where I am being silly.

Thankfully. The 6mm angle is cheaper than buying brackets from our local big box.

Cheaper and more hefty.

Being a numbskull such as I am. I like heft for the sake of heft.

In my albeit audiophool understanding of things. A heavier chassis will also be more damped in terms of vibration which at the margins can translate to a lower noise floor.

Thankfully. The 6mm angle is cheaper than buying brackets from our local big box.

Cheaper and more hefty.

Being a numbskull such as I am. I like heft for the sake of heft.

In my albeit audiophool understanding of things. A heavier chassis will also be more damped in terms of vibration which at the margins can translate to a lower noise floor.

Well maybe you’re creating a nice shielding effect using the thick steel.

Is good engineering to utilize a single component to accomplish more than one thing.

If it will be oriented to take advantage of that anyways…

Is good engineering to utilize a single component to accomplish more than one thing.

If it will be oriented to take advantage of that anyways…

6mm angle adds a lot of weight to the whole amplifier. Being a lightweight weakling, the extra weight would be an issue for me! 🙂

Simpson Strong-Tie A24 is what I have used, currently US $4.48 each at Home Depot in the USA.

Home Depot A24

Home Depot A24

Attachments

Well the transformer itself isn't exactly feather-like!6mm angle adds a lot of weight to the whole amplifier. Being a lightweight weakling, the extra weight would be an issue for me! 🙂

To me, this is a good option, and if using heavier transformers one could always use two brackets either mirror image or not, and mount the transformer between them in effect on an axle (the bolt (plastic if possible)). (Extra holes can be drilled (higher up) if needed to suit larger diameters of transformer).Simpson Strong-Tie A24 is what I have used, currently US $4.48 each at Home Depot in the USA.

Home Depot A24

No, you do not want to do that. You will end up with a shorted turn, which is a bad thing, unless you use a plastic bolt as you mentioned.

The Strongtie is actually strong enough for the transformers likely to be used.

The Strongtie is actually strong enough for the transformers likely to be used.

Well the transformer itself isn't exactly feather-like!

I have some amplifiers that I can barely lift. An extra few pounds would put them over the top!

- Home

- Design & Build

- Construction Tips

- Steel Angle as Toroidal Transformer bracket - Steel thickness?