Hello everybody,

I postet to early so I edit:

I bought a set of two Canton GLE 70 speakers (1978-1981) at a local thrift store. The guy there promised me that I can return them and get my money back and told me I should test them if I want them. So i took them with me.

This ist the speaker: https://www.hifi-wiki.de/index.php/Canton_GLE_70

I paid 30 for the set.

One speaker sounds very good the other has problems. I think that the midrange driver is gone but I'm not completly sure, could also be the tweeter.

The Speaker has a tweeter fuse built in on the backside. I switched the fuses of both speakers and after this both speakers sounded awful. When I switched them back the left one sounded good again.

I'm an absolute noob but I like the brand and model and thought guys that can build speakers could probably help me.

Thanks in advance!

I postet to early so I edit:

I bought a set of two Canton GLE 70 speakers (1978-1981) at a local thrift store. The guy there promised me that I can return them and get my money back and told me I should test them if I want them. So i took them with me.

This ist the speaker: https://www.hifi-wiki.de/index.php/Canton_GLE_70

I paid 30 for the set.

One speaker sounds very good the other has problems. I think that the midrange driver is gone but I'm not completly sure, could also be the tweeter.

The Speaker has a tweeter fuse built in on the backside. I switched the fuses of both speakers and after this both speakers sounded awful. When I switched them back the left one sounded good again.

I'm an absolute noob but I like the brand and model and thought guys that can build speakers could probably help me.

Thanks in advance!

Last edited:

Welcome to the forum!

The fuse holders may be corroded so try cleaning them. They may have to be replaced or bypassed. Also check the condition of the fuses.

By way of a bump, I am adding photos of the vintage (1978-81) Canton GLE.

To discover if those two drivers are indeed faulty, swap them over between the two cabinets to see if the fault follows them.

Do you have a multimeter with which to measure the DC resistance of the driver's voice coils in order to see if they are broken (open-circuit)?

The fuse holders may be corroded so try cleaning them. They may have to be replaced or bypassed. Also check the condition of the fuses.

By way of a bump, I am adding photos of the vintage (1978-81) Canton GLE.

One speaker sounds very good the other has problems. I think that the midrange driver is gone but I'm not completly sure, could also be the tweeter.

To discover if those two drivers are indeed faulty, swap them over between the two cabinets to see if the fault follows them.

Do you have a multimeter with which to measure the DC resistance of the driver's voice coils in order to see if they are broken (open-circuit)?

Last edited:

Funny the midrange could be a tweeter, too.

Maybe can be turned into a two way.

But I understand that keeping it original / only doing repair is attractive, too.

Maybe can be turned into a two way.

But I understand that keeping it original / only doing repair is attractive, too.

May I suggest a free Android APP, Frequency Sound Generator (by BialaMusic). A finger tone-sweep will tell you at what frequency they differ.

With three ways I always ask myself what a good FIR compensation could achieve making it phase linear and smoothing FR response if necessary.

I only use fullrange drivers. They are naturally phase linear if frequency response is linearized

I only use fullrange drivers. They are naturally phase linear if frequency response is linearized

Guys, note that MadWhisperer is a self-proclaimed "absolute noob".

I was interested in what the label around the tweeter fuse had to say.

I was interested in what the label around the tweeter fuse had to say.

Last edited:

Yes, I'm an absolute noob! Thanks for all the responses!

I don't have a multimeter and I also don't have a soldering iron. But I would really enjoy becoming able to repair things like this. So I would be open to invest in a multimeter and soldering equipment.

Swapping out the drivers should only require me to unscrew 4 screws and to desolder the drivers and then solder them back on, right?

Ebay also seems to have spare parts.

I don't have a multimeter and I also don't have a soldering iron. But I would really enjoy becoming able to repair things like this. So I would be open to invest in a multimeter and soldering equipment.

Swapping out the drivers should only require me to unscrew 4 screws and to desolder the drivers and then solder them back on, right?

Ebay also seems to have spare parts.

Yes, unscrew the four outer mounting screws. If you are lucky, the drivers may have push on connectors - otherwise you will need a soldering iron - nothing fancy required. And buy a cheap multimeter.

Well done! So you have one good loudspeaker. The other one has a defective high frequency unit AND a blown fuse.The Speaker has a tweeter fuse built in on the backside. I switched the fuses of both speakers and after this both speakers sounded awful. When I switched them back the left one sounded good again.

This is a pity!

Best regards

Bernd

no you do not need this for basic troubleshooting on a speaker. a meter a bit of common sense and practical advise sure....but yup some of that gear sure would be nice especially on my test bench!

a 1.5 v battery and a few short pieces of wire can do a lot of of quick testing of speaker drivers!

Hello again,

I don't jet have a multimeter or soldering iron but I did some acustic testing and took more pictures.

@wchang I downloaded the app. All tested frequencies sounded muffeld and weak on the defective speaker. At around 5.000 Hz there was almost no output from the defective speaker but very clear output from the non-defective one.

So I think there are at least 2 different problems: all over muffeld and weak sound and probably a defective tweeter?!

I also now noticed that the two speakers use different tweeters.

I took some pictures:

In terms of being a noob: I'm not emotionally attached to the speakers (jet) but I would like to learn. They only cost 30 Euro (the crazy heavy full brass stands they came with are worth more than that). If at some point it becomes clear that they can't be saved that's okay with me.

Edit: It seems hard to find replacement tweeters online sadly...

I don't jet have a multimeter or soldering iron but I did some acustic testing and took more pictures.

@wchang I downloaded the app. All tested frequencies sounded muffeld and weak on the defective speaker. At around 5.000 Hz there was almost no output from the defective speaker but very clear output from the non-defective one.

So I think there are at least 2 different problems: all over muffeld and weak sound and probably a defective tweeter?!

I also now noticed that the two speakers use different tweeters.

- The original (checked via photos) is labled 2697 and has a paper sticker with "3155"

- The replaced one is labeld 2697 and has a paper sticker with "2536"

I took some pictures:

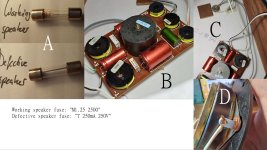

- A: The fuses in the two speakers differ

- B: I took a photo of the crossover of the defective speaker

- C: If I were to bypass the fuses, how would I do it? Would I just solder the two cabels goint to the fuse together?

- D: This is the replaced tweeter. There is only a little bit soldering going on but it seems relatively attached...

In terms of being a noob: I'm not emotionally attached to the speakers (jet) but I would like to learn. They only cost 30 Euro (the crazy heavy full brass stands they came with are worth more than that). If at some point it becomes clear that they can't be saved that's okay with me.

Edit: It seems hard to find replacement tweeters online sadly...

Attachments

Last edited:

This is a German "Wackelkontakt". A soldering iron and 60/40 solder with flux core are a must. (German "Elektroniklot" with lead and "Flussmittelseele"). Ask someone close to you.relatively attached...

I am pretty confident that you already moved at the Wackelkontakt. Did you crosscheck with a Battery? Credit @turk 182 . Does the Tweeter crackle?

My next step would be to find any working Tweeter. Just to check if the crossover is working at all. You may bridge the fuse, 1,25A is much to high anyway (sorry Canton).

Last edited:

Congrats, you can now identify and diagnose the most common sound issues such as frequency response (tonality). See if you can buy some alligator-clip wire and electrician's caps (look for them in this picture...). Then the most common capacitor/resistor/inductors to play around. Because their values add (C in parallel; R L in series) only a few are needed for doing experiments and "empirical design" by ear.

First you need to bypass the bad fuse/connection -- by brute force. Does the bad speaker play higher than 5khz? If you trace back from the bad tweeter to the capacitor in front of it, and read off the uF value, that should give a further hint how the tweeter is used.

First you need to bypass the bad fuse/connection -- by brute force. Does the bad speaker play higher than 5khz? If you trace back from the bad tweeter to the capacitor in front of it, and read off the uF value, that should give a further hint how the tweeter is used.

Attachments

Or I could just drive for 30 minutes and we can use your's (I live in Gelnhausen) ;D

p.s. my minimalist XO and notch filter design method

https://www.diyaudio.com/community/...ge-drivers-and-a-tweeter.391053/#post-7143129

https://www.diyaudio.com/community/...ge-drivers-and-a-tweeter.391053/#post-7143129

Missed it. Yes,C: If I were to bypass the fuses, how would I do it? Would I just solder the two cabels goint to the fuse together?

...or steal the working fuse for now and fiddle with the "Wackelkontakt" at the tweeter terminal.

I don't think that there is a Wackelkontakt. There is almost no solder applied but it seems to hold firm, it's not wobbeling.

A: fuses, one slow blow in the working speaker the other a fast blow with supported filament...while we tend to trust our eyes and both look good without a meter (or a old school flashlight lamp with our 1.5V battery) there's no telling that the fast blow (from the defective one) is good just by eye (sometimes the caps hide the damaged portion of the filament).

B:could we see the foilside of this x-over please.

C: i would jumper across the fuse holder (but i'm not there and can't see the layout and wiring)

D: mechanically solid does not mean electrically conductive...bad solder joints are everywhere...and could be why we all are gathered here..

- Home

- Loudspeakers

- Multi-Way

- Repairing German vintage speakers?