I'm the owner of a Marantz TTS15-1/Clearaudio Emotion turntable that I bought in the US and I moved to Italy. Basically after trying to save money by buying a step-down transformer and a pulley which ended being the same as the one I had from the US (by the way only the MarantzTTS15-1 for the Japan market have a 60 and 50hz pulley, EU and North America both share the same pulley) I realized that I needed to change the motor (synchronous AC motor) and that Clearaudio wants to rip me of of 400-500 euros...

Is it as simple as opening my current motor and finding an equivalent Premotec 50hz motor, ordering it and installing it? Do I need to do some soldering. Have no experience but willing to learn as it could be a fun projet. Not sure where to start and any help would be greatly appreciated! Thanks

Is it as simple as opening my current motor and finding an equivalent Premotec 50hz motor, ordering it and installing it? Do I need to do some soldering. Have no experience but willing to learn as it could be a fun projet. Not sure where to start and any help would be greatly appreciated! Thanks

From memory when I auditioned one, the motor & the power switch & the mains cable "come as one"... so... the easiest and safest way would be to indeed get the adequate motor from Clearaudio. If you choose to go down this path, you may as well order a 220V AC/50Hz motor for Italy with a schuko plug, and ditch the step-down transformer.

I think (but am not 100% sure) that you need to replace the rotor only, when switching from 60 to 50Hz.... It also depends on how they wound the primary.... i.e. how many poles. Ahhhhh the basics of synchronous AC motors... too lazy to dig deeper.

As you said, an interesting project to keep you occupied for a while...

... Clearaudio may be open to a swap option... 220/50 for 120 (110?)/60 ???

I think (but am not 100% sure) that you need to replace the rotor only, when switching from 60 to 50Hz.... It also depends on how they wound the primary.... i.e. how many poles. Ahhhhh the basics of synchronous AC motors... too lazy to dig deeper.

As you said, an interesting project to keep you occupied for a while...

... Clearaudio may be open to a swap option... 220/50 for 120 (110?)/60 ???

Last edited:

I've seen your post on Audiokarma, and my response is the same

You've fitted the belt around the 45rpm part of the pulley; 45 x 50/60 = 37.5 rpm, on the smaller diameter you'll be running at only 27.75rpm.

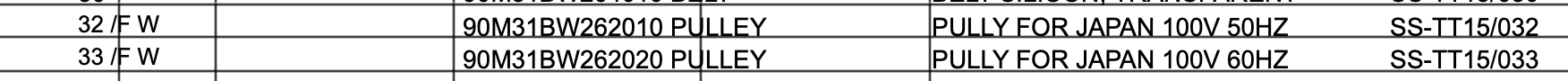

It appears that a 50Hz pulley is only available in Japan as that is the only place that has both 50Hz and 60Hz in different parts of the country.

However, as the motor is a 'standard' Premotec it should be feasible to find a suitable pulley from another turntable that uses this,

as long as the platter size is the same.

This is quite a common motor, some of the Pro-ject RPM series use these, and hopefully it should be possible to obtain a suitable pulley

If you do this you should also change the capacitor from the current 0.3uF to 0.47uF in order to reduce any vibration.

You've fitted the belt around the 45rpm part of the pulley; 45 x 50/60 = 37.5 rpm, on the smaller diameter you'll be running at only 27.75rpm.

It appears that a 50Hz pulley is only available in Japan as that is the only place that has both 50Hz and 60Hz in different parts of the country.

However, as the motor is a 'standard' Premotec it should be feasible to find a suitable pulley from another turntable that uses this,

as long as the platter size is the same.

This is quite a common motor, some of the Pro-ject RPM series use these, and hopefully it should be possible to obtain a suitable pulley

If you do this you should also change the capacitor from the current 0.3uF to 0.47uF in order to reduce any vibration.

ralph, If I understand correctly, even if I change the motor to the EU one that runs at 230V 50hz, I should change the pulley as well? That's the part I'm still confused about since all seems to point to the fact that EU and US share the same standard bigger pulley (44mm over the smaller 60Hz one, 37mmm)

Attachments

You're right, changing the motor will remove the need for the stepdown transformer, but, as far as I can see, there's no pulley suitable

for a 50Hz supply except in Japan, where different parts of the country use 50 or 60 H power supplies. Assuming the Premotec motor you have has a standard diameter shaft, eg 3mm? it should be feasible to obtain a suitable pulley from, for example, a Pro-ject RPM 9.

I've just had a look on ebay in the UK and there are several that look suitable at low cost; just be sure to get one for a drive around the whole platter(large), not just the subplatter (much smaller).

Analog Seduction in the UK can supply all parts for Pro-ject turntables; many of which use the same motor as your Marantz

eg https://www.ebay.co.uk/itm/295029566052.

for a 50Hz supply except in Japan, where different parts of the country use 50 or 60 H power supplies. Assuming the Premotec motor you have has a standard diameter shaft, eg 3mm? it should be feasible to obtain a suitable pulley from, for example, a Pro-ject RPM 9.

I've just had a look on ebay in the UK and there are several that look suitable at low cost; just be sure to get one for a drive around the whole platter(large), not just the subplatter (much smaller).

Analog Seduction in the UK can supply all parts for Pro-ject turntables; many of which use the same motor as your Marantz

eg https://www.ebay.co.uk/itm/295029566052.

Last edited:

Sorry Ralph, I think you didn't understand correctly what I said. I said if I change the motor, I don't see why I should find another pulley as there is only and only one pulley independently of EU or US. The change of the motor to the correct voltage and frequency is enough to insure correct speed. If I was just using the step-down transformer (as I've been doing) without changing the frequency, then the speed would be off and one option would be to secure another pulley, no?

Ralph is correct about the pulley, because both motors have the same number of poles and rotate at lower speed on 50Hz. My recollection of premotec 24 pole synchronous motors I have worked with is 300RPM at 60Hz and 250RPM at 50Hz, and this is regardless of the rated motor voltage.

(Hz x 60[seconds] x 2[polarity transition per cycle])/poles = unloaded motor speed

You will need a pulley too.

Ralph is extremely knowledgeable and would not steer you wrong.

(Hz x 60[seconds] x 2[polarity transition per cycle])/poles = unloaded motor speed

You will need a pulley too.

Ralph is extremely knowledgeable and would not steer you wrong.

I'm sorry, but you've got it wrong. All Premotec motors of that type will spin at 300rpm on a 60Hz supply, but only at 250rpm

when fed by a 50Hz supply, as in Europe. In order to get your turntable to spin at 33.33 rpm you will need a larger motor pulley.

I don't know the reason, but the pulley you obtained for 'Europe' is incorrect.

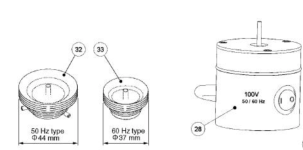

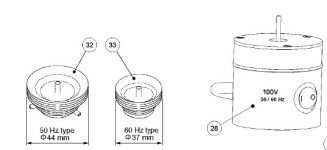

Here is an image extracted from the Japanese service manual

when fed by a 50Hz supply, as in Europe. In order to get your turntable to spin at 33.33 rpm you will need a larger motor pulley.

I don't know the reason, but the pulley you obtained for 'Europe' is incorrect.

Here is an image extracted from the Japanese service manual

Attachments

Ralph, the issue that I still can't wrap my head around is that the ''bigger pulley'' is the 50Hz which measures 44mm one and it is the same one that came with my original US table and the one that I received from a shop in EU. I measured them and they are both identical at 44mmm. there's not a bigger pulley, only a smaller one for the japan market.

The EU Marantz table manual as well as the EU one indicates only one size pulley. Besides if replace the current US motor with a EU one, I still don't get why I would need to change the ''standard bigger 44mm pulley'', my table would be equal to a EU bought one .

The EU Marantz table manual as well as the EU one indicates only one size pulley. Besides if replace the current US motor with a EU one, I still don't get why I would need to change the ''standard bigger 44mm pulley'', my table would be equal to a EU bought one .

It is odd, one question; did the turntable work correctly in the US with the '44'mm pulley fitted?

I am confused , assuming the speed was correct in the US using a 44 mm pulley running at 60 Hz you would need a (44 x 60) /50 = 52.8 mm pulley to get the same speed when running at 50 Hz .

The size ratio between the smaller pulley ( 37mm ) and the bigger pulley ( 44 mm ) is 1 : 1.2 which is the same as the ratio between the mains frequencies .

As these can be bought , I presume that these sizes are correct .

This however means that the US version should have been fitted with a " small " ( 37 mm ) pulley .

The premotec /airpax motor can run at 50 Hz / 250 rpm and at 60 Hz / 300 rpm , 220 v and 110 v versions are available .

The one you have got shows this on the label ( you have got a 110v version )

To run the table at 33.3 rpm the belt has to be on the smaller diameter of the stepped pulley

One question could you tell me what the diameter of platter is ?

Hope this helps , regards F.

The size ratio between the smaller pulley ( 37mm ) and the bigger pulley ( 44 mm ) is 1 : 1.2 which is the same as the ratio between the mains frequencies .

As these can be bought , I presume that these sizes are correct .

This however means that the US version should have been fitted with a " small " ( 37 mm ) pulley .

The premotec /airpax motor can run at 50 Hz / 250 rpm and at 60 Hz / 300 rpm , 220 v and 110 v versions are available .

The one you have got shows this on the label ( you have got a 110v version )

To run the table at 33.3 rpm the belt has to be on the smaller diameter of the stepped pulley

One question could you tell me what the diameter of platter is ?

Hope this helps , regards F.

the platter size is exactly: 296.86mm

The US version was fitted with the 44mm (total diameter pulley) as they shared the same l pulley size for EU and NA. As someone mentioned, the motor must be different between the 2 regions.

The US version was fitted with the 44mm (total diameter pulley) as they shared the same l pulley size for EU and NA. As someone mentioned, the motor must be different between the 2 regions.

On that basis it would appear that a 20 pole motor is used when the supply is at 50Hz, and the much more common 24 pole

for 60 Hz. This would be consistent with the Japanese market being fitted with the 20 pole motor, but a 'special' smaller

pulley for 60 Hz areas which would run at 360 rpm.

for 60 Hz. This would be consistent with the Japanese market being fitted with the 20 pole motor, but a 'special' smaller

pulley for 60 Hz areas which would run at 360 rpm.

the platter size is exactly: 296.86mm

Is the belt riding on the outer edge of this platter or there is an inside edge or a smaller diameter subplatter ?

Regards,

There really is a strange problem here; I've been looking for a motor that would run at 300rpm when driven by a 50Hz supply (20 pole),

They are almost completely unobtainable, the standard is 24 pole and is used by pretty much all turntable manufacturers except those who have moved to a DC motor( or a very few who used 16 pole motors).

Clearaudio make high quality TTs, but are not a large volume producer like Rega or Pro-ject, and it seems very unlikely that they would use a bespoke motor design for their products to be sold in areas of the world that use a 50Hz supply, especially when they are a German company and early sales would most likely have been their domestic market.

It would make much more sense to simply have one motor design and different pullies made to suit each market (50 or 60Hz)

They are almost completely unobtainable, the standard is 24 pole and is used by pretty much all turntable manufacturers except those who have moved to a DC motor( or a very few who used 16 pole motors).

Clearaudio make high quality TTs, but are not a large volume producer like Rega or Pro-ject, and it seems very unlikely that they would use a bespoke motor design for their products to be sold in areas of the world that use a 50Hz supply, especially when they are a German company and early sales would most likely have been their domestic market.

It would make much more sense to simply have one motor design and different pullies made to suit each market (50 or 60Hz)

Last edited:

A 4-pole motor run from 10Hz might be an interesting design point - subsonic drive current freq. may reduce hum pickup, 4-pole motors are easier to make (but more flywheel mass is likely needed to limit flutter). Active motor control means it could all be DC and run off a remote laptop PSU or similar, avoiding mains to the turntable itself and allowing portability.

Once we start playing around with different frequencies we might as well simply add a generator like the SG4, or RichB's Arduino.

At least that way the turntable runs the way it was designed.

I've sent the OP a pulley that I hope will work, at least at 33.3 rpm, if that's not accurate enough I'll look into alternative sources for a 60Hz supply

At least that way the turntable runs the way it was designed.

I've sent the OP a pulley that I hope will work, at least at 33.3 rpm, if that's not accurate enough I'll look into alternative sources for a 60Hz supply

How about using a portable power station with 110V/60Hz pure sine wave AC Outlet to power the TTS15-S1? No need a new motor and no modification is required.I'm the owner of a Marantz TTS15-1/Clearaudio Emotion turntable that I bought in the US and I moved to Italy. Basically after trying to save money by buying a step-down transformer and a pulley which ended being the same as the one I had from the US (by the way only the MarantzTTS15-1 for the Japan market have a 60 and 50hz pulley, EU and North America both share the same pulley) I realized that I needed to change the motor (synchronous AC motor) and that Clearaudio wants to rip me of of 400-500 euros...

https://www.amazon.com/dp/B09XD3VDQL

- Home

- Source & Line

- Analogue Source

- replacing a 60Hz motor with a 50Hz in a Clearaudio Emotion/Marantz TTS15-1