Unit is Audio Research SP10.

Until the unit has had ~20 minutes to warm up, I get intermittent noise out of the right channel that sounds similar to the sort of noise you get when your headphone mic is rubbing against your clothes, or wind is hitting a microphone. I can also cause the noise to happen directly by poking or gently pushing the first tube in the right channel of the phono stage. I have tried applying contact cleaner to the tube sockets.

I'm wondering if this is dirty sockets, old/failing tubes, or something else entirely?

Until the unit has had ~20 minutes to warm up, I get intermittent noise out of the right channel that sounds similar to the sort of noise you get when your headphone mic is rubbing against your clothes, or wind is hitting a microphone. I can also cause the noise to happen directly by poking or gently pushing the first tube in the right channel of the phono stage. I have tried applying contact cleaner to the tube sockets.

I'm wondering if this is dirty sockets, old/failing tubes, or something else entirely?

I swapped all of the phono stage tubes to the other channel, the noise still occurs on the right channel. Could the tube socket be loose?

I'd start with replacing higher values plate resistors . cooling spray could be used to pinpoint which one.

Duff soldered joint. Freezer spray used to be popular, but not near valves. What you need is a sharp pokey thing with an insulated handle so that you can poke joints whilst listening. It's not the valve because the fault didn't move with swapping valves. It could be a dying component, in which case, tapping them might reveal the faulty one.

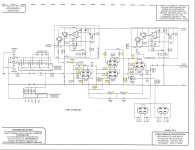

Attachments

Your first instinct to check the tube socket is the right place to start, and based on some sockets I have encountered might be the problem. Make sure there are no cold solder joints after cleaning the contacts with a small pipe cleaner. Do make sure that there is no voltage on anything before sticking the pipe cleaner in the socket pins.

I can investigate the sockets. Does it make sense that the issue would diminish as the system warmed up?

It is a possibility - I have had some problems with noisy tube sockets, mostly miniature 9 pins and UX-4. Passive components are the next thing to investigate.

Only resistors carrying current needs to check. Plate resistors usually have higher value, start with these.

Cathode resistors is a possibility, like electrolytics parallelling the cathode resistors.

Last and unlikely is the "grid stoppers" ( resistors in series with the grids)

Cathode resistors is a possibility, like electrolytics parallelling the cathode resistors.

Last and unlikely is the "grid stoppers" ( resistors in series with the grids)

In my diagram, would R-63 be a plate resistor, R-81 and R047 be "grid stoppers", and R-64 a cathode resistor?

Check Q15 as well. This FET is serving as a clamp diode which is a non-standard usage. I have had problems with noisy FETs due to exposure to excessive voltage. (This doesn't look like a very good idea to me.)

No, you would need to disconnect it at one end.

Taping resistors and other components is not effective unless they are physically broken - you typically need freeze spray to identify noisy resistors. (Might work with that jfet too.)

Inspecting the PCB for cold solder joints and retouching them can be surprisingly effective in RoHS era products, but I believe this one is pre lead free solder in the U.S. (Still take a close look with a magnifying glass or better still a loupe..)

I guess you don't have a scope? You might consider sending it to ARC or finding a good tech locally to fix it. Finding the source of random noise can be quite challenging even for the experienced - it is one of my least favorite problems to sort out.

Check out "Mend it Mark" on youtube for some good troubleshooting technique.

Taping resistors and other components is not effective unless they are physically broken - you typically need freeze spray to identify noisy resistors. (Might work with that jfet too.)

Inspecting the PCB for cold solder joints and retouching them can be surprisingly effective in RoHS era products, but I believe this one is pre lead free solder in the U.S. (Still take a close look with a magnifying glass or better still a loupe..)

I guess you don't have a scope? You might consider sending it to ARC or finding a good tech locally to fix it. Finding the source of random noise can be quite challenging even for the experienced - it is one of my least favorite problems to sort out.

Check out "Mend it Mark" on youtube for some good troubleshooting technique.

You guys are being very helpful, thank you so much.

I can try freeze spray, as well as inspecting for cold solder joints.

I do have a scope. How would I use it in this context, exactly?

I do have a tech I can send this to if necessary. I would rather learn by doing if I can.

I can try freeze spray, as well as inspecting for cold solder joints.

I do have a scope. How would I use it in this context, exactly?

I do have a tech I can send this to if necessary. I would rather learn by doing if I can.

Update: I got freeze spray, but it's not frosting up. I am in Sacramento, California, which is very dry, is that a factor?

Does it chill the component? You don't really want frost since that is conductive condensed moisture from the air.

- Home

- Amplifiers

- Tubes / Valves

- Noise from tube preamp phono stage - sounds like wind/contact noise on a microphone - can trigger by poking tube