Hello,

This is my first Subwoofer Build. I got the Material today and my Question is about the additional Bars to stiffen it. For the 394 mm inside I could set up to 3 per side.

The plates are 38mm/1 1/2 ".

ca. 70 L Internal Volume so around 2,8 cu ft

My Idea is to place 1 or 2 Pcs beacuse I want it to sound good and don´t wobble 😀

Is Dampening necessary and what is the most effective wall to dampen? the rear wall or the sides?

Should I leave it blank and decide about that after measuring ?

Thank you for your tipps.

Flo

This is my first Subwoofer Build. I got the Material today and my Question is about the additional Bars to stiffen it. For the 394 mm inside I could set up to 3 per side.

The plates are 38mm/1 1/2 ".

ca. 70 L Internal Volume so around 2,8 cu ft

My Idea is to place 1 or 2 Pcs beacuse I want it to sound good and don´t wobble 😀

Is Dampening necessary and what is the most effective wall to dampen? the rear wall or the sides?

Should I leave it blank and decide about that after measuring ?

Thank you for your tipps.

Flo

Greets!

Add them to all panels located at a golden ratio or an odd harmonic acoustic offset (3rd, 5th, 7th, etc.) and only ~0.707x the panel span i.d., i.e. we don't want to increase the corner seam's 'hot spot', so spaced to leave a gap to the opposing panels and if you feel the need, then use small scrap wood/whatever pieces/strips to 'bulletproof' them, though again, only ~0.707x the span to leave 'crush zones' to better protect what's inside in case of an accident.

Add a vertical, horizontal 't' brace to tie all six sides together to keep it from 'breathing' (allowing thinner panels) and offset such that with a little shimming it will apply a slight amount of pressure against the driver to mass load it once tightened down.

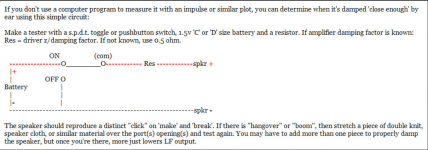

Damping/stuffing to 'taste' is best done using an impulse response measurement test or at least by ear, i.e. the DIYer's 'click test' (for best accuracy, 'sweet talk' a reasonably young female to do it since they have much better hearing in the critical BW); otherwise the pioneer's one of each parallel wall to start and go from there if need be, so typically top, one side, back at least as far down to a bit below the driver.

Add them to all panels located at a golden ratio or an odd harmonic acoustic offset (3rd, 5th, 7th, etc.) and only ~0.707x the panel span i.d., i.e. we don't want to increase the corner seam's 'hot spot', so spaced to leave a gap to the opposing panels and if you feel the need, then use small scrap wood/whatever pieces/strips to 'bulletproof' them, though again, only ~0.707x the span to leave 'crush zones' to better protect what's inside in case of an accident.

Add a vertical, horizontal 't' brace to tie all six sides together to keep it from 'breathing' (allowing thinner panels) and offset such that with a little shimming it will apply a slight amount of pressure against the driver to mass load it once tightened down.

Damping/stuffing to 'taste' is best done using an impulse response measurement test or at least by ear, i.e. the DIYer's 'click test' (for best accuracy, 'sweet talk' a reasonably young female to do it since they have much better hearing in the critical BW); otherwise the pioneer's one of each parallel wall to start and go from there if need be, so typically top, one side, back at least as far down to a bit below the driver.

Attachments

Hi,

thanks a lot for your reply. I got slightly confused to be honest. Would you be so kind to make a short sketch so I can see what you mean by that.

What I understood is the topic about the T-bar. Thats clear to me.

And that I should support all sides of the case.

I am sorry I cant imagine in my mind with how to 😀

I know the basic cases for the dayton drivers soundimport is selling, but I am not sure if it covers your idea.

The damping and testing is clear for me too.

Sorry I am a native german speaker so it is harder for me to follow you.

thanks a lot for your reply. I got slightly confused to be honest. Would you be so kind to make a short sketch so I can see what you mean by that.

What I understood is the topic about the T-bar. Thats clear to me.

And that I should support all sides of the case.

I am sorry I cant imagine in my mind with how to 😀

I know the basic cases for the dayton drivers soundimport is selling, but I am not sure if it covers your idea.

The damping and testing is clear for me too.

Sorry I am a native german speaker so it is harder for me to follow you.

Why begin with the worst possible shape in terms of stiffness - a cuboid. With a little imagination there are considerably better options than sticking a Band-Aid on a broken leg...

For a given volume displacement vs box volume, you could calculate the actual forces applied to the panels. Atmospheric pressure is approx 14.5psi or 101kPa.

If the woofer cone and rubber surround can withstand the pressure, the 'problem' is more likely to be something else: dipole or anti-phase vibration. You could estimate the amplitude at which the box will want to move by comparing the cone mass vs the remaining speaker mass + box mass.

If the woofer cone and rubber surround can withstand the pressure, the 'problem' is more likely to be something else: dipole or anti-phase vibration. You could estimate the amplitude at which the box will want to move by comparing the cone mass vs the remaining speaker mass + box mass.

Thanks a lot for your reply abstract.

If I see the box as a pressure chamber at 15 psi. I am at f (x) max at about 0,45 mm. Highest load on a panel is 2319 N

The box weight is 38 kg + 15 kg driver vs 0,384 kg cone

The ratio is 0,384 / ( 14,6 + 38) = 0,0066666

It seems like from the mechanical load aspect I have to support the panels at least once to be solid

So connecting every side asmyetric would be nice to do I think to be even more secure regarding the acoustic component. Do I have to round the edges of the bars I put in for a sealed sub?

Thanks a lot.

Should I post pics here once I finished.

If I see the box as a pressure chamber at 15 psi. I am at f (x) max at about 0,45 mm. Highest load on a panel is 2319 N

The box weight is 38 kg + 15 kg driver vs 0,384 kg cone

The ratio is 0,384 / ( 14,6 + 38) = 0,0066666

It seems like from the mechanical load aspect I have to support the panels at least once to be solid

So connecting every side asmyetric would be nice to do I think to be even more secure regarding the acoustic component. Do I have to round the edges of the bars I put in for a sealed sub?

Thanks a lot.

Should I post pics here once I finished.

Hi

I am finished and it is buttersmooth. The big boy got 57 Kg in total and is powered by an Crown XLS 1502 in Bridged mode. The amp is silent and slim and easy to use for me and got enough Oomph to dig into heavy movies.

I tested it until 90 DBa at my listening position and it still sounds relaxed.

Xmax is no limit here because I use only around 12-14 mm at best.

The bass is superclean. It can draw and drag a bassline like a sharp knife.

I couldn´t find any bad sounding music.

The Project was a huge success for me.

Aurix TM1:

I am finished and it is buttersmooth. The big boy got 57 Kg in total and is powered by an Crown XLS 1502 in Bridged mode. The amp is silent and slim and easy to use for me and got enough Oomph to dig into heavy movies.

I tested it until 90 DBa at my listening position and it still sounds relaxed.

Xmax is no limit here because I use only around 12-14 mm at best.

The bass is superclean. It can draw and drag a bassline like a sharp knife.

I couldn´t find any bad sounding music.

The Project was a huge success for me.

Aurix TM1:

- Home

- Loudspeakers

- Subwoofers

- RSS390-22 Sealed Enclosure Stiffness / Decision issues about bars to stiffen up