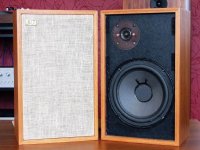

I own a pair of Acoustic Research AR15 which date from around the year 2000 I guess. They were sold in germany for little money. These drivers have metal cone drivers - the tweeter JBL like with origami folding of the aluminium diaphram - and sound superbly good if you change the MKT C before the tweeter for a MKP C. I wonder how in the sixties even KEF built loudspeakers with sandwich drivers - in my eyes a state of the art technology for loudpeaker diaphragms - but later they switched to plastic cones.

So it can happen that in loudspeaker history a technology gets forgotten and later it is produced again by someone else. Known are sandwich diaphragms from ETON or Zellaton

Podzus Görlich held a patent just some years after the Rice and Kellog loudspeaker for a loudspeaker diaphragm made of hard foam with one side of the diaphragm covered with aluminium foil - here on the history in german language: https://www.zellaton.de/de/geschichte.html

I heard of Bozac loudspeakers - some were built with aluminium foil on the diaphragm in the fifties of the last century.

I am a big fan of loudspeakers with aluminium foil. So I do that myself if you cannot buy it. I take care to buy drivers with copper rings which minimizes distortion.

So it can happen that in loudspeaker history a technology gets forgotten and later it is produced again by someone else. Known are sandwich diaphragms from ETON or Zellaton

Podzus Görlich held a patent just some years after the Rice and Kellog loudspeaker for a loudspeaker diaphragm made of hard foam with one side of the diaphragm covered with aluminium foil - here on the history in german language: https://www.zellaton.de/de/geschichte.html

I heard of Bozac loudspeakers - some were built with aluminium foil on the diaphragm in the fifties of the last century.

I am a big fan of loudspeakers with aluminium foil. So I do that myself if you cannot buy it. I take care to buy drivers with copper rings which minimizes distortion.

Attachments

Is there a good book on loudspeaker history? Who built the first metal cone for loudspeakers? Was Emil Podzus the first making a stiff cone with hard foam (onesided with aluminium foil).

https://de.wikipedia.org/wiki/Emil_Podszus

Ted Jordan made in the 60ies the first metal cones?

Just use some translation.

See citation of D.A Barlow on sandwich cones:

https://www.diyaudio.com/community/...how-off-my-new-18in-build.365764/post-6741724

https://de.wikipedia.org/wiki/Emil_Podszus

Ted Jordan made in the 60ies the first metal cones?

Just use some translation.

See citation of D.A Barlow on sandwich cones:

https://www.diyaudio.com/community/...how-off-my-new-18in-build.365764/post-6741724

Some prefer their own -->Two true-believers patting each other´s back and thinking "the whole World agrees with us" 😉

Earl has left the chat for good: relatable.

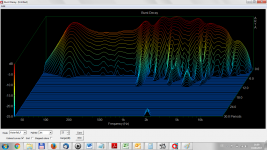

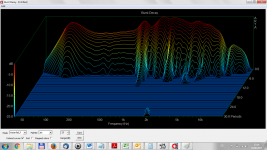

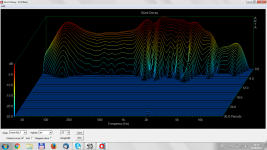

I have measurements before and after for many drivers. But often I did not wait until the glue has completely evaporated. I did not always document if the measurement was made immediately after the diaphragm tuning or not.

I have here however a Saba Greencone without aluminium, with one side aluminium and both sides aluminium. In the ones with aluminium the glue has not evaporated. After some time (I do not know exactly when, but certainly after two weeks) the water component in the glue has evaporated. Frequency response in the higher frequencies are damped by the heavier cone. But after some time the loss in the highs comes back as the diaphragm lightens up. However the aluminium used was very thin as this is a fullrange driver and weight should not be added too much.

As you put aluminium onto the cone it takes longer time to evaporate than usual as the foil prohibits a fast evaporation, especially if you do the diaphragm covering in one turn just to finish the job, I often do it like this. You should not force evaporation by heating the driver because bubbles can occur and you destroy the driver not only optically.

I have here however a Saba Greencone without aluminium, with one side aluminium and both sides aluminium. In the ones with aluminium the glue has not evaporated. After some time (I do not know exactly when, but certainly after two weeks) the water component in the glue has evaporated. Frequency response in the higher frequencies are damped by the heavier cone. But after some time the loss in the highs comes back as the diaphragm lightens up. However the aluminium used was very thin as this is a fullrange driver and weight should not be added too much.

As you put aluminium onto the cone it takes longer time to evaporate than usual as the foil prohibits a fast evaporation, especially if you do the diaphragm covering in one turn just to finish the job, I often do it like this. You should not force evaporation by heating the driver because bubbles can occur and you destroy the driver not only optically.

Attachments

I'm reading it, but there is not much more to say. The data simply stands on its own. All anyone can use to support contrary positions is "Well, it sounds good to me!"Earl has left the chat for good: relatable.

I've measured these old speakers that are so highly regarded and most of them are pretty bad. (I suspect that many weren't nearly as bad when new, but just like the frog in boiling water, one never seems to notice the slow change.) Many can be seen on my website, just peruse the list.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Research AR-7