I recently bought a new power transformer with a winding rated for 6.3V @ 5A. The winding is oversized as the amplifier will only be drawing 3A max of heater current. After testing it with the actual tubes which draw about 2.8 amps the voltage is extremely high at over 9 volts. Unloaded I read over 12V on the winding. Throughout all tests the HV winding was left unloaded, but I don't think it should matter that much.

I understand transformers are not perfect devices and there can be some fluctuation in the voltage, but this is not acceptable in the long run.

Is this to be expected and my order was too oversized or the transformer was wound badly?

I'm reaching out here as I may be able to ask for a refund or at least a fix if the transformer isn't supposed to be behaving like this.

Side note: assuming I can't get a refund or get it fixed, would it be cheaper to build a regulator (considering the trafo itslef costs about 50EUR)?

Keep in mind the space under the chassis is tight and I'm not looking to bring in that much more heat to dissipate.

I'll say that I'm slightly skeptical about the regulator as the current being involved here is fairly high and I fear the power wasted to heat would be huge.

I understand transformers are not perfect devices and there can be some fluctuation in the voltage, but this is not acceptable in the long run.

Is this to be expected and my order was too oversized or the transformer was wound badly?

I'm reaching out here as I may be able to ask for a refund or at least a fix if the transformer isn't supposed to be behaving like this.

Side note: assuming I can't get a refund or get it fixed, would it be cheaper to build a regulator (considering the trafo itslef costs about 50EUR)?

Keep in mind the space under the chassis is tight and I'm not looking to bring in that much more heat to dissipate.

I'll say that I'm slightly skeptical about the regulator as the current being involved here is fairly high and I fear the power wasted to heat would be huge.

9 volts unloaded would be believable, but 12 is way high. I have seen 30% regulation figures on cheap Chinese split bobbin types (72 VA EI Triads) but 50% is way over the top. Load the HV to full with a dummy load and see where things are. If the regulation is really that bad you don’t want to use it anyway.

That's to be expected if you're drawing considerably less current than the winding is designed for. But, as noted, you should not be getting 12v unloaded on a 6.3v winding.I recently bought a new power transformer with a winding rated for 6.3V @ 5A. The winding is oversized as the amplifier will only be drawing 3A max of heater current. After testing it with the actual tubes which draw about 2.8 amps the voltage is extremely high at over 9 volts. Unloaded I read over 12V on the winding. Throughout all tests the HV winding was left unloaded, but I don't think it should matter that much.

I understand transformers are not perfect devices and there can be some fluctuation in the voltage, but this is not acceptable in the long run.

Is this to be expected and my order was too oversized or the transformer was wound badly?

I'm reaching out here as I may be able to ask for a refund or at least a fix if the transformer isn't supposed to be behaving like this.

Side note: assuming I can't get a refund or get it fixed, would it be cheaper to build a regulator (considering the trafo itslef costs about 50EUR)?

Keep in mind the space under the chassis is tight and I'm not looking to bring in that much more heat to dissipate.

I'll say that I'm slightly skeptical about the regulator as the current being involved here is fairly high and I fear the power wasted to heat would be huge.

Another factor is the voltage rating of the primary vs the actual voltage from the wall. If the primary is rated for 120v (or 117v or ??) and your wall voltage is higher then the voltage on the filament winding will be higher still.

Is this a Chinese PT? People who buy their cheap tube amps often have this issue because their PTs often have primaries that are rated for 110v so when your wall voltage is over 120v, which is almost always the case, the secondary voltages are much higher than they would be at 110v.

What voltage is the primary rated for?

If you can return it and find one with a 3A winding the voltage will be closer. And try to find one whose primary is as close to your actual wall voltage as possible. You might be able to find one whose primary is higher than your wall voltage as some PTs have multiple primaries.

If the voltage ends up a bit too high the simplest way to drop it is by using a couple of resistors. Resistors are available in various values between 0.05 ohms and 1 ohm. Do the math, divide by 2 and use one on each leg. I typically use 5w cement wirewounds.

Some of you have asked the same questions, I'll answer to them all once here:

About the possible fixes:

It'll take me some time to run tests with the HV loaded as I cannot really test it with a dummy load. A 30w 1k resistor (which is about what I'll need) is not easily available around where I live. Still, in my previous experiences, the load has never been this bad, in fact, it has barely changed with or without the primary loaded.

The primary is rated for 230V and the voltage at the wall was 234V.Line voltage is not fixed. What was it rated for?

Not at all. It is made locally from an Italian company which was also recomended on this site previously. I guess bad batches happen to everyone.Is this a Chinese PT?

9 volts unloaded would be believable, but 12 is way high

That's my exact thinking. I'm really tempted to send the manufacturer an email as these numbers are really off.50% is way over the top

About the possible fixes:

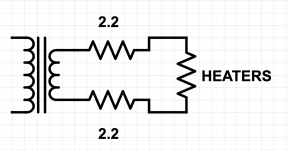

- I've already bought 2x2.2ohm resistors rated at 10W, I've put them in parallel to the tube heaters but the voltage didn't drop at all. I'll try putting one on each winding in series (as shown in the attached picture)

- Reach out to the manufacturer who has already provided replacements when the faul was on his side

It'll take me some time to run tests with the HV loaded as I cannot really test it with a dummy load. A 30w 1k resistor (which is about what I'll need) is not easily available around where I live. Still, in my previous experiences, the load has never been this bad, in fact, it has barely changed with or without the primary loaded.

Think outside the box on the dummy load. Think of what you have in your stash - even if you put 10 or 20 in series or parallel. Doesn’t have to be pretty or permanent. And overloading by a factor of two for a three second test is no big deal. A bunch of 10-20k 2W MOXs would do the job and would be a normal item to have on hand for building tube amps.

Have you tried using the two 2.2 Ohm resistors in SERIES with your tube heaters instead of PARALLEL? I guess that will make a big difference!

Regards, Gerrit

Regards, Gerrit

My guess is that he was trying to put additional load on the winding and see if it dropped any.

Could be a mislabeled 120V rated. Is it hot?... The primary is rated for 230V and the voltage at the wall was 234V....

I'll try them for sure!Have you tried using the two 2.2 Ohm resistors in SERIES with your tube heaters instead of PARALLEL? I guess that will make a big difference!

Regards, Gerrit

Yes indeed that's what I was trying to do but had no luck.My guess is that he was trying to put additional load on the winding and see if it dropped any.

Therefore following y'all suggestions I'll be wiring up the heaters as follows (I meant to attach it earlier but forgot):

Attachments

No, there you have 4.4 ohm in series with filaments instead of suggested 1 ohm.

First answer: is your "6.3V" filament winding center tapped pr you make an artificial tap out of 2 00 ohm resistors?

First answer: is your "6.3V" filament winding center tapped pr you make an artificial tap out of 2 00 ohm resistors?

12V offload voltage is ridiculous. Complain to the manufacturer.

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- Transformer winding with higher voltage than marketed