Hi all - just took delivery of a new pair of Faital Pro 10PR320-16 drivers, and was surprised to measure fs at 65 & 68 for the two drivers (out of the box) when spec fs is quoted at 50Hz.

They've come down a bit (both to c 60Hz) after a few hours of burn in - but on last measurement they had both stopped changing.

Is this level of difference (c.20%) from specs normal for Faital drivers? Given I need a pair of 50hz drivers, I am feeling a bit hard done by.

Anyone have any thoughts?

They've come down a bit (both to c 60Hz) after a few hours of burn in - but on last measurement they had both stopped changing.

Is this level of difference (c.20%) from specs normal for Faital drivers? Given I need a pair of 50hz drivers, I am feeling a bit hard done by.

Anyone have any thoughts?

Do run a simulation if the measured parameters affect how they work in a box compared to published specs. Stiffer suspenension increase Fr but also decrease Vas and increase Qt. They work agonistically on tuning so the change can be quite small.

How do you burn in?

I connect the amp to my cell phone and use a signal generator app and send a signal a bit below Fr in your case say 50 Hz and then crank up the volume, with the drivers in free air until it really streach the suspension, without risking damaging the speakers.

How do you burn in?

I connect the amp to my cell phone and use a signal generator app and send a signal a bit below Fr in your case say 50 Hz and then crank up the volume, with the drivers in free air until it really streach the suspension, without risking damaging the speakers.

Thanks for comments.

I'm burning in with laptop running REW driving a varying signal between 20-50hz through an amp with one driver on each channel. Its difficult to know exactly how close it is to x-max - but visually it looks to be running 6 or 7 mm excursion and xmax is speced at a bit over 7mm, so im reluctant to push it much harder (its close to max vol on the Amp in any event)

Airvoid - interested in your comment about needing to burn in mounted vertically? Everything I've read suggested mounting wasn't important for burn in, and ive just got the drivers sitting on a bench without a mount. Perhaps that may make a dif? I'm going to cut a test baffle tomorrow so will run a few hours in that and see if it makes a difference.

I'll also do the T/S parameters tomorrow and see how they look - I was hoping to get the units measuring close to spec fs prior - but maybe that wont be possible.

I'm burning in with laptop running REW driving a varying signal between 20-50hz through an amp with one driver on each channel. Its difficult to know exactly how close it is to x-max - but visually it looks to be running 6 or 7 mm excursion and xmax is speced at a bit over 7mm, so im reluctant to push it much harder (its close to max vol on the Amp in any event)

Airvoid - interested in your comment about needing to burn in mounted vertically? Everything I've read suggested mounting wasn't important for burn in, and ive just got the drivers sitting on a bench without a mount. Perhaps that may make a dif? I'm going to cut a test baffle tomorrow so will run a few hours in that and see if it makes a difference.

I'll also do the T/S parameters tomorrow and see how they look - I was hoping to get the units measuring close to spec fs prior - but maybe that wont be possible.

There's a LOT of misinformation on amateur / hobbyists sites, on Youtube etc but there's also a lot of really good info, problem is to sift out the bs from the gems.

Here's a manufacturers link:

https://www.scan-speak.dk/datasheet/tech/Scan-Speak_Technote01_TS-measurement.pdf

Exerpt:

"Measurement conditions

Before starting measurement of the parameters, the drive unit must be burned-in by exposing it to a (preferably) sine tone at a frequency slightly below or at the initial resonance frequency and then applying a voltage large enough for the driver to move almost to its maximum excursion. If the driver starts clipping, which is clearly audible, turn back the voltage. The T/S parameters should always be measured on a burned-in driver, because the compliance of a completely new driver will change quite a bit in the first few minutes of excitation. So if the data is to be used for system design, the burned-in dataset is the useful one.

Another thing often overlooked is the conditions under which the driver is measured. Even small drivers will exhibit vibration when exposed to a large enough voltage so it is imperative that the driver is securely clamped during measurement e.g. in a toolshop vice. In order to avoid any influence from physical boundaries make sure that there

is room around the measurement setup. Finally, the driver should be positioned vertically so that gravity doesn ́t influence the cone area."

Here's a manufacturers link:

https://www.scan-speak.dk/datasheet/tech/Scan-Speak_Technote01_TS-measurement.pdf

Exerpt:

"Measurement conditions

Before starting measurement of the parameters, the drive unit must be burned-in by exposing it to a (preferably) sine tone at a frequency slightly below or at the initial resonance frequency and then applying a voltage large enough for the driver to move almost to its maximum excursion. If the driver starts clipping, which is clearly audible, turn back the voltage. The T/S parameters should always be measured on a burned-in driver, because the compliance of a completely new driver will change quite a bit in the first few minutes of excitation. So if the data is to be used for system design, the burned-in dataset is the useful one.

Another thing often overlooked is the conditions under which the driver is measured. Even small drivers will exhibit vibration when exposed to a large enough voltage so it is imperative that the driver is securely clamped during measurement e.g. in a toolshop vice. In order to avoid any influence from physical boundaries make sure that there

is room around the measurement setup. Finally, the driver should be positioned vertically so that gravity doesn ́t influence the cone area."

Hmm Interesting, thanks, I hadn't read that before.

Actually on re-reading, i think they mean clamping vertically for measuring rather than for burn in. Definitely for measuring that is the case.

Regardless, I'll give the drivers another 12 hrs overnight an see if that gets me anywhere. And then might give them a bit more in baffles.

I'm guessing I've just bought 60hz drivers marketed as 50hz!

Actually on re-reading, i think they mean clamping vertically for measuring rather than for burn in. Definitely for measuring that is the case.

Regardless, I'll give the drivers another 12 hrs overnight an see if that gets me anywhere. And then might give them a bit more in baffles.

I'm guessing I've just bought 60hz drivers marketed as 50hz!

I'm guessing I've just bought 60hz drivers marketed as 50hz!

As someone said further up, run the measured T/S parameters through the simuator. You'll probably find minimal changes in the frequency response. Fs isn't the sole indicator for how low a driver will go.

Chris

Break in does not take "hours" to perform - 10 or 15 minutes with the cone driven to about Xmax and a signal applied at the resonance freuqency is all you need. This is just "cracking' the glue on the spider for the most part. You must use high excursion to do this properly. Any longer and the motor will start heating up.

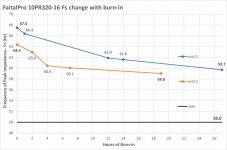

For the sake of interest as much as anything I thought id post the Fs results over the burnin period.

Pretty clear changes in the drivers for both drivers.

In a nutshell:

Interestingly, although both drivers started at dif points, they have ended up within 1Hz, so at least they are consistant - maybe one of them had a bit of burn-in previously?

Despite burn-in improvement, both drivers have settled c 10Hz (20%) above their specified Fs.

As pointed out in a number of previous posts Fs is just one of many parameters, (the rest of which I am planning to test today) however regardless of other parameters, a driver with a 20% dif Fs is not going to behave the same way in a multi driver system. It is likely to require a different enclosure design and essentially a complete speaker redesign.

From the tone of the other respondents no one seems very surprised at such a large deviation from spec - is this normal for "pro" drivers?

Cheers Paul.

Pretty clear changes in the drivers for both drivers.

In a nutshell:

- Fs reduced by a total of 8-12% over period from 64.4 to 59.0 and 67.5 to 59.7 Hz

- rate of reduction decreasing from 1-2%/hr to about 0.2% an hr

- One driver has had c 27 hrs and the other c 19hrs and both now appear relatively stable

Interestingly, although both drivers started at dif points, they have ended up within 1Hz, so at least they are consistant - maybe one of them had a bit of burn-in previously?

Despite burn-in improvement, both drivers have settled c 10Hz (20%) above their specified Fs.

As pointed out in a number of previous posts Fs is just one of many parameters, (the rest of which I am planning to test today) however regardless of other parameters, a driver with a 20% dif Fs is not going to behave the same way in a multi driver system. It is likely to require a different enclosure design and essentially a complete speaker redesign.

From the tone of the other respondents no one seems very surprised at such a large deviation from spec - is this normal for "pro" drivers?

Cheers Paul.

Attachments

Are you sure you have eliminated mechanical losses in your test jig?

I’m only asking because this issue has come up before on the forum, notably in camplos enormous two-way thread.

Best Rgds

-a

I’m only asking because this issue has come up before on the forum, notably in camplos enormous two-way thread.

Best Rgds

-a

Hi,

A member measured the Faital 12PR320 after breaking in and the Fs was very near to Faital datasheet and certainly small differences were the result of the driver rest hours differences. It measures not the same if the driver had 2 hours of rest or 24 hours if I am correct.

datasheet said 42 hz and the user measured between 40 hz and 47 hz according the method, room temperature and so on. Sims on Leap from another member corrected the number more towards 47 hz if my memory serves me well.

Faital gives numbers of breaking in units and give an average numbers on several tested. Also for you sim, I assume one has to take a Fs from a warm driver is what interresting us ( when there is a playback). So it decreases sligthy the Fs number. People say it doesn't fundamentally change the result and anyway we are at frequencies mostly dominated by room and loudspeaker localisation. The members conclued the datasheet from Faital was reliable for the T&S.

A member measured the Faital 12PR320 after breaking in and the Fs was very near to Faital datasheet and certainly small differences were the result of the driver rest hours differences. It measures not the same if the driver had 2 hours of rest or 24 hours if I am correct.

datasheet said 42 hz and the user measured between 40 hz and 47 hz according the method, room temperature and so on. Sims on Leap from another member corrected the number more towards 47 hz if my memory serves me well.

Faital gives numbers of breaking in units and give an average numbers on several tested. Also for you sim, I assume one has to take a Fs from a warm driver is what interresting us ( when there is a playback). So it decreases sligthy the Fs number. People say it doesn't fundamentally change the result and anyway we are at frequencies mostly dominated by room and loudspeaker localisation. The members conclued the datasheet from Faital was reliable for the T&S.

Last edited:

Ahh thanks diyiggy. So it seems either there's a screwup in my testing methodology, or I've got a rogue pair of unexpectedly out of spec drivers.

My initial impedance tests were done unmounted just sitting on a desk, as I was really just verifying when burn in was completed. Since then I've repeated the tests with the drivers mounted vertically and got materially the same results.

Thanks for the suggestion airvoid but I'm thinking it's probably not a mechanical losses issue, as I think that should have caused the measurements to change when I remeasured the drivers mounted, but it was the same.

I'm testing via PC soundcard and REW with a 100ohm sense resistor as per REW directions.

The shape of the impedance curves looks correct as does min R, just Fs is measuring c 10hz too high.

Any thoughts on anything which might be incorrect with my testing or calibration setup which would only effect the resonance peak position?

Cheers Paul.

My initial impedance tests were done unmounted just sitting on a desk, as I was really just verifying when burn in was completed. Since then I've repeated the tests with the drivers mounted vertically and got materially the same results.

Thanks for the suggestion airvoid but I'm thinking it's probably not a mechanical losses issue, as I think that should have caused the measurements to change when I remeasured the drivers mounted, but it was the same.

I'm testing via PC soundcard and REW with a 100ohm sense resistor as per REW directions.

The shape of the impedance curves looks correct as does min R, just Fs is measuring c 10hz too high.

Any thoughts on anything which might be incorrect with my testing or calibration setup which would only effect the resonance peak position?

Cheers Paul.

Thanks for the suggestion airvoid but I'm thinking it's probably not a mechanical losses issue, as I think that should have caused the measurements to change when I remeasured the drivers mounted, but it was the same.

That is exactly what is bugging me.

You are determining the self resonance of a pretty strong motor and moving system, the frame and magnet should be absolutely stationary with respect to the moving mass. Any relative movement caused by the structure or the system will alter the outcome. For a pro bass driver this pretty much entails a metal frame bolted to a concrete floor or wall.

Hmm - I hear you. The REW impedance test is done on a very low signal. When running the measurement it is audible but at extremely low volume - with no visible cone excursion - nothing like the movement of the burn-in procedure, and no noticeable vibrations. I guess I haven't ruled it out completely but I just cant see mechanical issues moving Fs by 20% in small signal tests - especially now it is bolted into a 20mm ply stand.

I have had a closer look at the impedance plots of the 2 drivers next to the spec plot to see if anything else popped out as weird. There are 2 small abnormalities (only c 1-2ohm) in the spec plot at c. 600hz and just over 1100Hz, both of which are also reflected at correct freqs and magnitudes in the measured curves - so im thinking that if there was a testing methodology issue surely those small peaks wouldn't be so accurate? Kind of brings me back to thinking the drives might just be outliers?

Frankly i hope im wrong and have just stuffed something up, but running out of alternatives!

I dont suppose I could have messed up something in the REW calibration? - Might have another look at that - I must say I didn't find the directions particularly clear.

Cheers Paul.

I have had a closer look at the impedance plots of the 2 drivers next to the spec plot to see if anything else popped out as weird. There are 2 small abnormalities (only c 1-2ohm) in the spec plot at c. 600hz and just over 1100Hz, both of which are also reflected at correct freqs and magnitudes in the measured curves - so im thinking that if there was a testing methodology issue surely those small peaks wouldn't be so accurate? Kind of brings me back to thinking the drives might just be outliers?

Frankly i hope im wrong and have just stuffed something up, but running out of alternatives!

I dont suppose I could have messed up something in the REW calibration? - Might have another look at that - I must say I didn't find the directions particularly clear.

Cheers Paul.

Attachments

I suggest you just try and move or rock the uppermost part of the stand with a finger, if it moves ever so little you have losses there that will alter the fs value.

This just to be sure, on the other hand if you are absolutely certain I would return the drivers asap. 20% is way to out of spec to be reasonable, an OEM would not tolerate that.

It also bugs me that both drivers are exactly the same amount out of spec. Test I’ve seen in Voicecoil magazine of Fp drivers have not pointed at ‘happy numbers’ like this.

Best Rgds

-a

This just to be sure, on the other hand if you are absolutely certain I would return the drivers asap. 20% is way to out of spec to be reasonable, an OEM would not tolerate that.

It also bugs me that both drivers are exactly the same amount out of spec. Test I’ve seen in Voicecoil magazine of Fp drivers have not pointed at ‘happy numbers’ like this.

Best Rgds

-a

Last edited:

Would it make sense to ask manufacturer what were the measuring conditions and if you could recreate those?

Sometimes suspension parts consistency changes.

Sometimes suspension parts consistency changes.

Stand is rock solid to the touch.I suggest you just try and move or rock the uppermost part of the stand with a finger, if it moves ever so little you have losses there that will alter the fs value.

This just to be sure, on the other hand if you are absolutely certain I would return the drivers asap. 20% is way to out of spec to be reasonable, an OEM would not tolerate that.

It also bugs me that both drivers are exactly the same amount out of spec. Test I’ve seen in Voicecoil magazine of Fp drivers have not pointed at ‘happy numbers’ like this.

Best Rgds

-a

yes agreed - the fact that both drives are the same is making me think there must be something systemic in the measuring system.

I just measured resonant frequency directly on one of the drives with a 100r and a multimeter by finding the freq giving the max voltage on a Multimeter. That came out at between 32-36Hz bolted to the stand, which is too far the other way although the MM is not really accurate enough to provide much certainty.

Also i have read a couple of other guides on measuring TS parameters directly without the software, and they are both directing that the drives shouldn't be mechanically coupled to anything - just hung in free air for the measurements - so maybe thats something for tomorrow - along with trying to nail down Fs on a scope. If I can independently nail down Fs close to spec then I know its something with the impedance measurement set-up/calibration.

cheers Paul.

Yep, i've made contact with Faital - so hopefully can move in that direction once theyre back after the weekend.Would it make sense to ask manufacturer what were the measuring conditions and if you could recreate those?

Sometimes suspension parts consistency changes.

Thanks for the suggestion!

cheers Paul.

Look again at TBTL's suggestion.Measured fs depends on the drive level. You could try different levels. 2 V should be OK.

Most manufacturers use a small signal to determine T/S parameters, like 0.1 V or even less. However others use a large signal, such as 1 V or more. It makes a difference. Any woofer will have a different Fs at a 0.05 V level than it will at a 5 V level, and all the other T/S parameters change as well.

There is no right answer, and both small signal T/S and large signal T/S have pros and cons.

j.

- Home

- Loudspeakers

- Multi-Way

- How much above Fs should a new driver be?