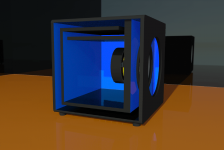

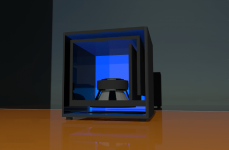

what do you think would be the ideal cross-sectional area for these four drivers? The plan is to get it into an ODMLTL enclosure that looks like the drawing/sketch up (with 4 drivers?)

I need enough room to fit the drivers this way, but the Vas in these car audio drivers wants to be kind of small and sort of making it difficult??

if playing with the SIM is there a comfortable CSa that you would recommend that’s bigger or smaller( or whatever) you feel is ‘best’? what I have there is an example can be looked at in the wizard as the Upper section will be lined with open cell foam in a decent thickness as well as layers of poly filled required to knock down the endpoints of the bandwidth which at the bottom are kind of curly as you might notice???

Wood is too expensive and I simply don’t feel confident doing anything right now without calling in the voice of collective reason(diy audio). ( third generation Toyota four Runner SUV, btw)

I need enough room to fit the drivers this way, but the Vas in these car audio drivers wants to be kind of small and sort of making it difficult??

if playing with the SIM is there a comfortable CSa that you would recommend that’s bigger or smaller( or whatever) you feel is ‘best’? what I have there is an example can be looked at in the wizard as the Upper section will be lined with open cell foam in a decent thickness as well as layers of poly filled required to knock down the endpoints of the bandwidth which at the bottom are kind of curly as you might notice???

Wood is too expensive and I simply don’t feel confident doing anything right now without calling in the voice of collective reason(diy audio). ( third generation Toyota four Runner SUV, btw)

Attachments

Last edited by a moderator:

Ignore the above, I've decided I'm not sure what you want based on your sim, so please attach the Export file.

I was wondering if you thought 1400cm2 in 2 folds and 700cm2 in the last was a bit too big? But I need it kind of like that in order to be able to fit the driver as pictured ?Ignore the above, I've decided I'm not sure what you want based on your sim, so please attach the Export file.

I would suggest to remove the 180 degrees bend and use two rounded 90 degrees bends instead. The vent for the top drivers then goes to the top of the cabinet, while the vent for the bottom drivers goes to the bottom.

OK, HR 'says' your MLTL's main pipe is ~286.608 L Vs (4) T/S max flat BRs = ~41.514 L, so an over the top acoustically huge amount, but so high an aspect ratio (long) that my original sleepless 'knee jerk' response was correct in that with just a ~13.37 cm^2 CSA you'll need to make it with one pair of sides big enough to mount one 12"/side (opposed) and the other two below them, all centered at the offset point.

I forgot about the folding, so with the drivers centered at a fold joint the last fold (vent) is long enough you won't be able to mount the bottom driver on this side IF I'm visualizing correctly as this is one of those times when I had to resort to scaled 3D drawings to figure it out.

I forgot about the folding, so with the drivers centered at a fold joint the last fold (vent) is long enough you won't be able to mount the bottom driver on this side IF I'm visualizing correctly as this is one of those times when I had to resort to scaled 3D drawings to figure it out.

Hmm, what I'm 'seeing' in HR is a simple folded MLTL with a long vent.I would suggest to remove the 180 degrees bend and use two rounded 90 degrees bends instead. The vent for the top drivers then goes to the top of the cabinet, while the vent for the bottom drivers goes to the bottom.

yuck… Yeah I understand what you’re saying I was hoping there was something I was overlooking. you kicked down the brick wall that was a stupid hurdle in my head so to speak🙂 thx!OK, HR 'says' your MLTL's main pipe is ~286.608 L Vs (4) T/S max flat BRs = ~41.514 L, so an over the top acoustically huge amount, but so high an aspect ratio (long) that my original sleepless 'knee jerk' response was correct in that with just a ~13.37 cm^2 CSA you'll need to make it with one pair of sides big enough to mount one 12"/side (opposed) and the other two below them, all centered at the offset point.

I forgot about the folding, so with the drivers centered at a fold joint the last fold (vent) is long enough you won't be able to mount the bottom driver on this side IF I'm visualizing correctly as this is one of those times when I had to resort to scaled 3D drawings to figure it out.

back to the convergent/divergent aligned to 3 x 1/4 antinode <>< the latter

as the cheat in non turbulent reduction toward a low tuned long TL shape

( just like a phase change from steam to the condensate uses an air ejector in a turbine exit steam plant , or a sandblaster creates that low pressure area at the same location as the high velocity exist—-> I’m lining things up with the physical attributes(shapes) at the same point the harmonic (freq/ wavelength parts at max/min) produces the same scenario as well(Air particle velocity versus pressure?)

< seen as:

(here) <

as the cheat in non turbulent reduction toward a low tuned long TL shape

( just like a phase change from steam to the condensate uses an air ejector in a turbine exit steam plant , or a sandblaster creates that low pressure area at the same location as the high velocity exist—-> I’m lining things up with the physical attributes(shapes) at the same point the harmonic (freq/ wavelength parts at max/min) produces the same scenario as well(Air particle velocity versus pressure?)

^^ it ‘sorta works’ but telling horn response is trickyback to the convergent/divergent aligned to 3 x 1/4 antinode <>< the latter

as the cheat in non turbulent reduction toward a low tuned long TL shape

( just like a phase change from steam to the condensate uses an air ejector in a turbine exit steam plant , or a sandblaster creates that low pressure area at the same location as the high velocity exist—-> I’m lining things up with the physical attributes(shapes) at the same point the harmonic (freq/ wavelength parts at max/min) produces the same scenario as well(Air particle velocity versus pressure?)

Personally I think 700 cm^2 for 4 drivers is too small (by a factor 1.414 as an educated guess), there is a way to accurately simulate this in HR but not in OD mode.

its 1400for ~210 cm abd 700 cm2 for ~ 90?Personally I think 700 cm^2 for 4 drivers is too small (by a factor 1.414 as an educated guess), there is a way to accurately simulate this in HR but not in OD mode.

currently these are i 800cm2 @ ~210 cm and 3200cm2 @ ~120 (in a ‘Roar’ pair)

umax18👍🏻👍🏻😍Personally I think 700 cm^2 for 4 drivers is too small (by a factor 1.414 as an educated guess), there is a way to accurately simulate this in HR but

Attachments

I went by Sd in the HR model.

507cm^0.5 = 22.516cm / 0.7854 = 11.289in = 12" driver.

Seeing that the enclosure is 3 drivers wide and most trunks can handle a 36-38" wide enclosure. Looks like 6 12's to me.

Here is a 6 driver BP6P enclosure that I designed for a P3 Volvo S60. My son has 2018 long wheel base AWD P3 and the wife has a 2016 short wheel base FWD P3.

I have 8 $29 JBL GX1200's from Best Buy lying around.

507cm^0.5 = 22.516cm / 0.7854 = 11.289in = 12" driver.

Seeing that the enclosure is 3 drivers wide and most trunks can handle a 36-38" wide enclosure. Looks like 6 12's to me.

Here is a 6 driver BP6P enclosure that I designed for a P3 Volvo S60. My son has 2018 long wheel base AWD P3 and the wife has a 2016 short wheel base FWD P3.

I have 8 $29 JBL GX1200's from Best Buy lying around.

its always nice when you pop in from time to time 🙂I went by Sd in the HR model.

507cm^0.5 = 22.516cm / 0.7854 = 11.289in = 12" driver.

Seeing that the enclosure is 3 drivers wide and most trunks can handle a 36-38" wide enclosure. Looks like 6 12's to me.

Here is a 6 driver BP6P enclosure that I designed for a P3 Volvo S60. My son has 2018 long wheel base AWD P3 and the wife has a 2016 short wheel base FWD P3.

I have 8 $29 JBL GX1200's from Best Buy lying around.

View attachment 1084633

i always wonder if ‘Blaine Perkins’ is a relative, in Ohio too(parts express employee) . A speaker wizard as well …That's guy! It's nice being appreciated.

- Home

- Loudspeakers

- Subwoofers

- if building for this driver: