I just replaced two flaky bias trimmers in a JVC VR-5660 receiver. Problem is, the settings of the originals are an unreliable reference for what the new ones should be set to, and I don't have a copy of the service manual. Assuming I'm measuring across the emitter resistors between X3 and X7 and then X4 and X8, what's a safe voltage to shoot for?

Schematic says 10mV across each 0.5 ohm.

I would verify the correct ohm values of each emitter resistor (with power off) first.

A very good DVM and proper test leads are required for measuring 10mVDC.

I would verify the correct ohm values of each emitter resistor (with power off) first.

A very good DVM and proper test leads are required for measuring 10mVDC.

Right in front of my face.

So I can measure across the two pairs of emitter resistors for each channel, aiming for 20mV per pair?

So I can measure across the two pairs of emitter resistors for each channel, aiming for 20mV per pair?

First verify resistors are 0.5 ohms each, if you can.

Then check for 10mV across each resistor. They will vary in current,

but adjust each channel for average of 10mV each.

Then check for 10mV across each resistor. They will vary in current,

but adjust each channel for average of 10mV each.

The resistors measured ok. Adjusted bias for the right channel, and had it holding roughly around 10mV per resistor, but not super steady. Eventually it started spiking to 30mV, and then later over 150mV. The other channel biased up fine. Needless to say, I shut it down.

Some background: This bias spike has happened before, and I've been trying to sort out why for the last few days. I thought I had narrowed it down to the bias trimmer. Both driver boards are removable PCB cards, so I pulled them both and tested every component on each, comparing my results. The transistors seem fine, based on a go-no-go tester and the curves from my octopus tester. Caps were ok when tested with my Peak Atlas ESR70. Of course, this doesn't mean something isn't failing under operating voltage. The solder joints did look much worse on the bad board, so I resoldered every one. Also, when I plug the "good" board (left) into the right side slot, it behaves fine.

The only anomaly besides the flaky bias trimmer was the following that I measured with the cards removed:

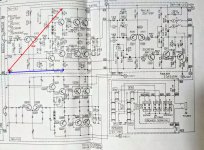

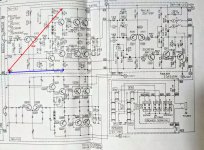

Resistance between 704 and R714 across a 10nF cap on the back side of the board. Red line on the schematic.

Good board: Open

Bad board: 1.9M and rising

Resistance between 704 and R725. Blue line on the schematic.

Good board: 15.5M and slowly rising

Bad board: -1M and slowly dropping (autoranging meter added a minus sign in front of the resistance measurement). A different meter just showed 1M.)

Some background: This bias spike has happened before, and I've been trying to sort out why for the last few days. I thought I had narrowed it down to the bias trimmer. Both driver boards are removable PCB cards, so I pulled them both and tested every component on each, comparing my results. The transistors seem fine, based on a go-no-go tester and the curves from my octopus tester. Caps were ok when tested with my Peak Atlas ESR70. Of course, this doesn't mean something isn't failing under operating voltage. The solder joints did look much worse on the bad board, so I resoldered every one. Also, when I plug the "good" board (left) into the right side slot, it behaves fine.

The only anomaly besides the flaky bias trimmer was the following that I measured with the cards removed:

Resistance between 704 and R714 across a 10nF cap on the back side of the board. Red line on the schematic.

Good board: Open

Bad board: 1.9M and rising

Resistance between 704 and R725. Blue line on the schematic.

Good board: 15.5M and slowly rising

Bad board: -1M and slowly dropping (autoranging meter added a minus sign in front of the resistance measurement). A different meter just showed 1M.)

Connect a DVM between the X704/X705 driver bases, and observe the voltage reading when the current surges happen.

Does the reading change?

Does the reading change?

With the DVM between the bases off X704 and X705, the reading doesn't change. It started off at -1.80V, and climbed to 2.2V with the bias at approximately 4mV per emitter resistor. When I tried adjusting the trimmer higher, the bias shot up to over 300mV, but the voltage between the driver bases didn't seem to be rising in tandem.

Ok, look for a problem after the driver stage then. Carefully compare the good and bad channels.

When checking the emitter resistors again, I found that R723 in the bad channel was open. I replaced it and then plugged in the good board to see if the outputs were ok. They all biased up fine. Also retested the drivers. They're ok. So maybe that emitter was borderline and the stress of the current surges finally took it out. I wasn't 100 percent about the in-circuit resistance measurements of R721, so I went ahead and replaced that too.

Checked all of the other resistors after the drivers, and other than being several being slightly out of spec (a little higher than the 10 percent tolerance), nothing on the bad board was significantly different from the good board. Plugged in the bad board, and the current is still shooting up once I get over about 3 or 4mV per resistor of bias. The problem is there, but I'm just not finding it.

Checked all of the other resistors after the drivers, and other than being several being slightly out of spec (a little higher than the 10 percent tolerance), nothing on the bad board was significantly different from the good board. Plugged in the bad board, and the current is still shooting up once I get over about 3 or 4mV per resistor of bias. The problem is there, but I'm just not finding it.

If the problem follows the board, it has to be on there somewhere. If the voltage across the

driver outputs remains constant, that points to the following circuitry as the problem.

But, maybe it still could be the bias network: the diodes, or R25/R26, since you've replaced the pot.

As a last resort you could move the bias network parts from the good board to the bad board.

driver outputs remains constant, that points to the following circuitry as the problem.

But, maybe it still could be the bias network: the diodes, or R25/R26, since you've replaced the pot.

As a last resort you could move the bias network parts from the good board to the bad board.

I'll try replacing the STV-3 diode string, if only to eliminate a variable. If that doesn't do it, then it's on to R25 and R26. I did just check the new bias trimmer with my Simpson 270, so that I could more easily monitor the resistance as I swept the wiper from leg to leg--no evidence of it losing contact anywhere.

Sure, if you have the right parts, it can't hurt. Did you check the output while adjusting? Might be oscillating.

Hi Matt,

You are definitely oscillating (from private email with pictures). The STV-3 diode is fine, and I hate people messing with them because they are fragile where the wire leads enter the body. Please handle them with great care. A stack of three diodes isn't quite the same, but will do when the only other option is to scrap the unit.

The negative resistance measurement indicates a stored voltage, so any reading is inaccurate. Discharge all the electrolytic capacitors and test again, just the driver card removed. Let me know. That is just a supply rail to ground and I expect higher leakage currents. DO check C11 (0u22) and R9 (5R6), if these are open the amplifier will be unstable and prone to oscillation.

Other capacitors to check would be C704 (47uF 63V), C702 (47uF 6V3) and C703 (47uF 63V). Normally there would be a small capacitor across R708 for HF compensation. Check the good channel to see if one was added later and is missing on the bad side. If you replace C702, use a good quality name brand part, as high a voltage rating that will fit properly up to about 63VDC. It is worth ordering these from Digikey or Mouser, measure the lead spacing and order a new one with the same spacing or one that will fit the hole spacing if that is wider. This capacitor can have a large impact on sound quality.

To trigger on the high frequency waveform, decrease the time / div on the horizontal (you might be uSec per division instead of mSec per division), set your trigger level for the approximate centre of the wave form and make sure your trigger source is set to that channel (Y1 I'm guessing) with no filters. Rising or falling edge should work and set to auto, which I think you are judging from the photos.

-Chris

You are definitely oscillating (from private email with pictures). The STV-3 diode is fine, and I hate people messing with them because they are fragile where the wire leads enter the body. Please handle them with great care. A stack of three diodes isn't quite the same, but will do when the only other option is to scrap the unit.

The negative resistance measurement indicates a stored voltage, so any reading is inaccurate. Discharge all the electrolytic capacitors and test again, just the driver card removed. Let me know. That is just a supply rail to ground and I expect higher leakage currents. DO check C11 (0u22) and R9 (5R6), if these are open the amplifier will be unstable and prone to oscillation.

Other capacitors to check would be C704 (47uF 63V), C702 (47uF 6V3) and C703 (47uF 63V). Normally there would be a small capacitor across R708 for HF compensation. Check the good channel to see if one was added later and is missing on the bad side. If you replace C702, use a good quality name brand part, as high a voltage rating that will fit properly up to about 63VDC. It is worth ordering these from Digikey or Mouser, measure the lead spacing and order a new one with the same spacing or one that will fit the hole spacing if that is wider. This capacitor can have a large impact on sound quality.

To trigger on the high frequency waveform, decrease the time / div on the horizontal (you might be uSec per division instead of mSec per division), set your trigger level for the approximate centre of the wave form and make sure your trigger source is set to that channel (Y1 I'm guessing) with no filters. Rising or falling edge should work and set to auto, which I think you are judging from the photos.

-Chris

Thanks for weighing in Chris. I appreciate the guidance from both you and rayma.

I discharged the caps and rechecked the resistance readings from pin 704 (black probe) to R714 and R725 (red). Now both the bad and good board readings are in rough agreement: between 4.5M and 6.5M respectively.

I retested C702, C703, and C704 again with my Peak Atlas ESR70. They all show a reasonable capacitance (approx. 50-55uF) and ESR. There's no capacitor across R708 on either board. The only cap that's on both boards and not shown in the schematic is a 10nF ceramic from pin 704 to R714.

C11 and R9, the zobel network, read close to their counterparts in the other channel. I suppose this doesn't surprise me, since the "good" board works fine when plugged into the channel the bad board normally resides in. The "bad" board has issues with both channels. Of course, this brings me back to the issue being with the board itself. . . .

I discharged the caps and rechecked the resistance readings from pin 704 (black probe) to R714 and R725 (red). Now both the bad and good board readings are in rough agreement: between 4.5M and 6.5M respectively.

I retested C702, C703, and C704 again with my Peak Atlas ESR70. They all show a reasonable capacitance (approx. 50-55uF) and ESR. There's no capacitor across R708 on either board. The only cap that's on both boards and not shown in the schematic is a 10nF ceramic from pin 704 to R714.

C11 and R9, the zobel network, read close to their counterparts in the other channel. I suppose this doesn't surprise me, since the "good" board works fine when plugged into the channel the bad board normally resides in. The "bad" board has issues with both channels. Of course, this brings me back to the issue being with the board itself. . . .

I have found defective PCBs before, but they are extremely rare. I don't think this would be your issue here, but never say never.

These testers aren't worth very much, sorry. My LCR meter cost over $2,500 in the mid 1980's and measures DA (HP 4263A). This is the critical measurement to look at as well as the capacitance. Additionally, you test at frequencies the capacitor operates at. All these cheap testers do not use sine waves. ESR might matter with a supply capacitor, but that isn't even close to the whole picture. For supply capacitors, looking at the waveform in operation with an oscilloscope tells you a great deal more. I later bought an ESI and before had an HP 4261A. These meters do measure ESR as well, but I don't bother.

You have an AC stability problem. That means either high AC impedance at high frequencies on the supply lines (bypass capacitors), or you have an issue with a capacitor in the signal path. Check the 10nF supply bypass capacitors and the traces to make sure they are in good condition. What I really don't like about this amp is the lack of high frequency stability components. No output inductor isn't great, same for small pre-driver collector - base capacitors (47 to 100 pF is typical). Don't go adding things without a plan. This is basically a very minimalist design that excluded everything that could possibly be left out. The bias circuit design is just terrible, and open pot fails destructively for instance. You might be in a situation where the AC stability work that was removed or not done at all needs to be worked out. This is one of those designs where the replacement of any transistor with a different type or beta range could result in an unstable amplifier.

Ignore leakage or resistance pin 704 to the other test points. This isn't critical at all unless the current is high. Adding some electrolytic caps across the 10nF units will increase leakage, but might solve your problem, 10uF to 47uF should do it if it were to help. It's just good design practice to have them, that's the only reason I brought those up.

These testers aren't worth very much, sorry. My LCR meter cost over $2,500 in the mid 1980's and measures DA (HP 4263A). This is the critical measurement to look at as well as the capacitance. Additionally, you test at frequencies the capacitor operates at. All these cheap testers do not use sine waves. ESR might matter with a supply capacitor, but that isn't even close to the whole picture. For supply capacitors, looking at the waveform in operation with an oscilloscope tells you a great deal more. I later bought an ESI and before had an HP 4261A. These meters do measure ESR as well, but I don't bother.

You have an AC stability problem. That means either high AC impedance at high frequencies on the supply lines (bypass capacitors), or you have an issue with a capacitor in the signal path. Check the 10nF supply bypass capacitors and the traces to make sure they are in good condition. What I really don't like about this amp is the lack of high frequency stability components. No output inductor isn't great, same for small pre-driver collector - base capacitors (47 to 100 pF is typical). Don't go adding things without a plan. This is basically a very minimalist design that excluded everything that could possibly be left out. The bias circuit design is just terrible, and open pot fails destructively for instance. You might be in a situation where the AC stability work that was removed or not done at all needs to be worked out. This is one of those designs where the replacement of any transistor with a different type or beta range could result in an unstable amplifier.

Ignore leakage or resistance pin 704 to the other test points. This isn't critical at all unless the current is high. Adding some electrolytic caps across the 10nF units will increase leakage, but might solve your problem, 10uF to 47uF should do it if it were to help. It's just good design practice to have them, that's the only reason I brought those up.

Great info. Even if I don't get this sorted (and I still hope to), there are several lessons in here that I'll benefit from.

At this point, I think my next step will be to replace the electrolytic capacitors. If that doesn't improve matters, then I'll add some capacitance across the 10nF caps as you suggest.

At this point, I think my next step will be to replace the electrolytic capacitors. If that doesn't improve matters, then I'll add some capacitance across the 10nF caps as you suggest.

Okay, please understand I'm not trying to say the amp is crap, I'm just pointing out technical observations that impact what you are seeing. I tend to be blunt.

I hope some of the ideas do help you solve your issue. Feel free to ask more.

I hope some of the ideas do help you solve your issue. Feel free to ask more.

- Home

- Amplifiers

- Solid State

- JVC VR-5660: Bias Figure?