Hi all,

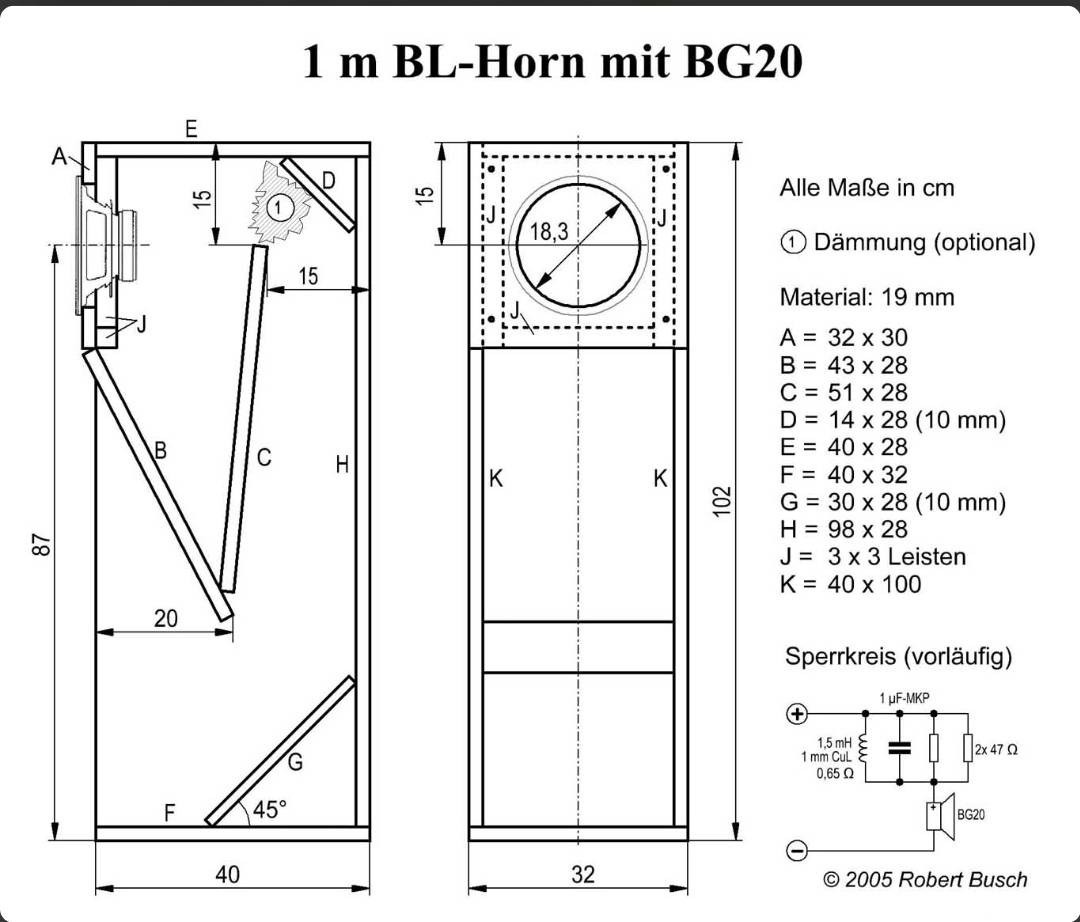

I have decide to make my first project. I choose full range speakers for easy connection purpose. No problem with crossovers etc. I have purchase two Visaton BG20 and waiting now for delivery. Two similar project I found online, both are horn/tube style.

I do not have accurate saw to cut board with necessary precision so need to buy with cut service, most probably from B&Q (I live in UK). Material will be plywood 18mm.

I have decide to make my first project. I choose full range speakers for easy connection purpose. No problem with crossovers etc. I have purchase two Visaton BG20 and waiting now for delivery. Two similar project I found online, both are horn/tube style.

I do not have accurate saw to cut board with necessary precision so need to buy with cut service, most probably from B&Q (I live in UK). Material will be plywood 18mm.

If you don't have an accurate saw i suggest you hire a carpenter to build for you. I did so and have no regrets, apart from wishing i had done so sooner and not made costly compromises on inferior designs. i'll keep an eye on the thread all the same as i also own that driver so it is of interest, not too many builds out there, good bang for the buck though.

BG20 + TQWT is a natural sound that feels good on my ears.

I get some 18mm, hardwood plywood from B&Q, cut for size in the shop. Two boards (1220x2440mm) with cutting service, cost me less than £100. I gonna stored flat for a few days before gluing it together.

Attachments

Next day - next step. Holes for speakers are cutted. Should I use a gasket between the hole and the speaker? It`s gonna be a huge horn🙂

Attachments

Last edited:

Yes, gasket between driver and cabinet is highly recommended. You dont vant air pressure leaking there.

Looks good, any idea where I can buy it?

https://www.ebay.co.uk/itm/141741874573?hash=item2100795d8d:g:JrUAAOSw7gxerH-C

Is that any good?

https://www.ebay.co.uk/itm/141741874573?hash=item2100795d8d:g:JrUAAOSw7gxerH-C

Is that any good?

The neodymium magnets I used are 8 pieces of 30mmφx2mm.

The magnetic flux density is 200 millistella.

110 yen (about $1.00) per piece in Japan.

I think that there is no problem if the size is close.

https://www.ebay.co.uk/itm/393408537433?hash=item5b98f9e359:g:FqgAAOSwCTNg0sgZ:PL_CLK|clp:2047675

The magnetic flux density is 200 millistella.

110 yen (about $1.00) per piece in Japan.

I think that there is no problem if the size is close.

https://www.ebay.co.uk/itm/393408537433?hash=item5b98f9e359:g:FqgAAOSwCTNg0sgZ:PL_CLK|clp:2047675

Gluing in progress. Plywood is not as strait as MDF. Have a problem with tension. Need few days to finish first box.

Attachments

-

IMG_20220401_144214.jpg293.1 KB · Views: 130

IMG_20220401_144214.jpg293.1 KB · Views: 130 -

IMG_20220401_143729.jpg188.3 KB · Views: 129

IMG_20220401_143729.jpg188.3 KB · Views: 129 -

IMG_20220401_144224.jpg295 KB · Views: 130

IMG_20220401_144224.jpg295 KB · Views: 130 -

IMG_20220402_123436.jpg217.8 KB · Views: 138

IMG_20220402_123436.jpg217.8 KB · Views: 138 -

IMG_20220402_124836.jpg291.9 KB · Views: 146

IMG_20220402_124836.jpg291.9 KB · Views: 146 -

IMG_20220403_115736.jpg371.2 KB · Views: 152

IMG_20220403_115736.jpg371.2 KB · Views: 152 -

IMG_20220403_120230.jpg294.7 KB · Views: 127

IMG_20220403_120230.jpg294.7 KB · Views: 127 -

IMG_20220403_121328.jpg387.5 KB · Views: 126

IMG_20220403_121328.jpg387.5 KB · Views: 126

First enclosure are done today, need only fill the gaps and holes with wood filler. Now I choosing paint colour. I did a sound test, not bad at all🙂

Attachments

-

IMG_20220407_180238.jpg304.2 KB · Views: 140

IMG_20220407_180238.jpg304.2 KB · Views: 140 -

IMG_20220407_172832.jpg225 KB · Views: 131

IMG_20220407_172832.jpg225 KB · Views: 131 -

IMG_20220409_122717.jpg442.8 KB · Views: 140

IMG_20220409_122717.jpg442.8 KB · Views: 140 -

IMG_20220409_125933.jpg354.8 KB · Views: 132

IMG_20220409_125933.jpg354.8 KB · Views: 132 -

IMG_20220407_120419.jpg335.5 KB · Views: 130

IMG_20220407_120419.jpg335.5 KB · Views: 130 -

IMG_20220407_121627.jpg338.8 KB · Views: 132

IMG_20220407_121627.jpg338.8 KB · Views: 132 -

IMG_20220407_140031.jpg215.5 KB · Views: 143

IMG_20220407_140031.jpg215.5 KB · Views: 143

To be honest, I had some problems with crimping. I did my best, using the tool attached on photo. I know is not perfect, but I was doing it for the very first time, holds tight. Soldering sims to be even more difficult. Besides, I have no soldering gun.

Attachments

You should learn to solder. It’s really not that hard. Just experiment with a few pieces of wire. Just remember to heat the wire and let the wire melt the solder.To be honest, I had some problems with crimping. I did my best, using the tool attached on photo. I know is not perfect, but I was doing it for the very first time, holds tight. Soldering sims to be even more difficult. Besides, I have no soldering gun.

......with Sta-Brite or similar spec/quality silver bearing solder for best performing joint. 😉 The downside is one needs at least a 45 W iron [ancient 60 W Ungar still soldering bras, steel rods, etc., just fine for me] or mini-blowtorch.Better yet, solder them.

FYI/FWIW, 'tight' doesn't = a good electrical connection, i.e. done right with the right tools, crimps, for the app it's a cold weld joint [void free] and why soldering it also is a good plan for DIYers that can't justify the tool's/component's relatively high cost unless making a lot of something.holds tight

- Home

- Loudspeakers

- Full Range

- BG20 Horn Project