After having fooled around in this hobby for more than 25 years, I would like to share the "rules" I follow when I build two-way ported loudspeaker cabinets.

1. The first I do is to choose a midwoofer with Qts around 0,30 for standmounts and around 0,40 for floorstanders, that seems to be the sweet-spot. And for midwoofers I prefer motors with copper above and below the air gap (Seas Excel, Scanspeak Revelator), not inside the gap (Satori, Audio Technology, Wavecor). Midwoofers with copper inside the gap may sound superior in the midrange and in the lower treble, but I my opinion they lack punch and power in the bass and lower midrange. And I like the midwoofer's Mms to be no lighter/heavier than 7-8 cm2/gram, that is another sweet-spot that goes well with the Qts.

2. I then use some software to estimate the cabinet volume and port tuning, aiming for a system-Q around 0,70. The cabinet can be larger, but not smaller than 0,70. If space permits, I like the port area to be 30-35% of the midwoofers Sd. And I like to place the round(!) port on the front. The port opening inside the cabinet should be placed on a small baffel. The inside opening schould be placed in a golden ratio distance from the top and bottom of the cabinet.

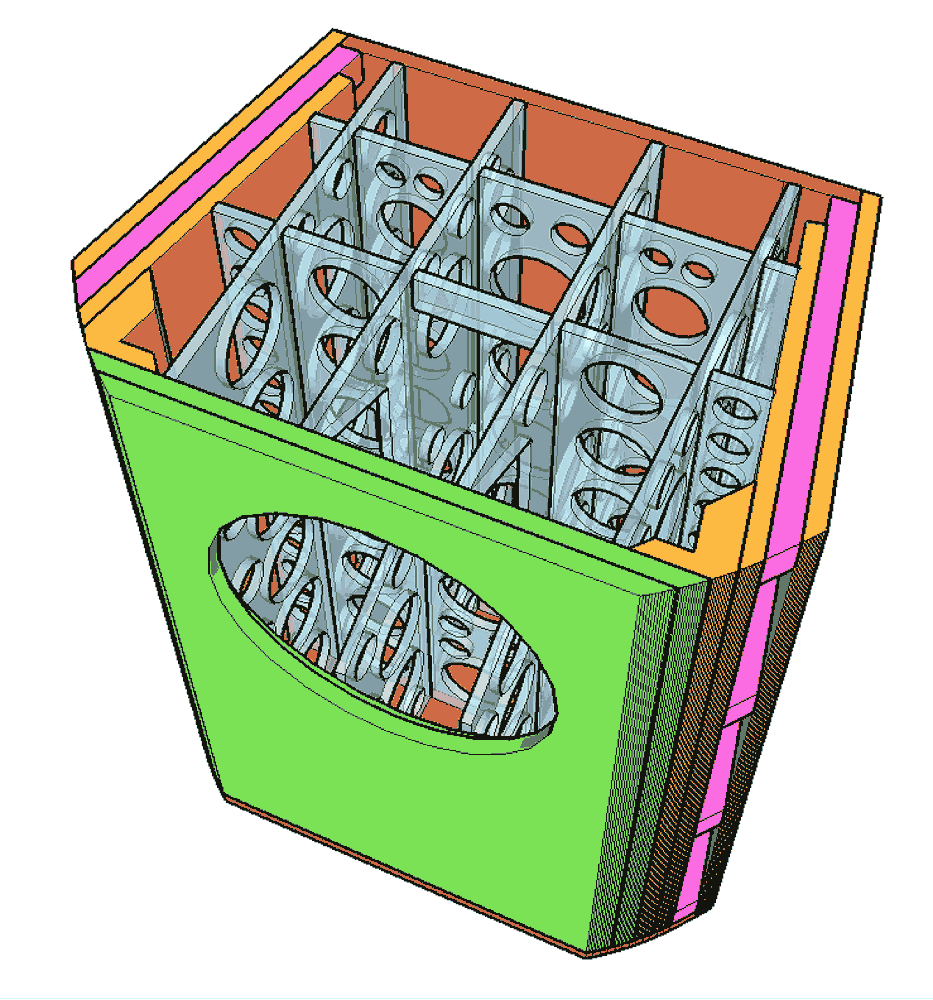

3. And then the time consuming work begins. I know you can add stuffing inside the cabinet to balance the port response and to damp standing waves, this is a quick and easy fix but in my experience, the less damping inside the cabinet, the better. Lining the walls with ¼" wool felt is ok but even the slightest amount of volume stuffing almost always lead to a less lively and less open and less powerful loudspeaker. So I never stuff. Instead I build the cabinet with angled reflectors at the top and bottom, with lots of non-symmetrical shelf-braces in between, to break up the standing waves without choking the driver/port.

4. Most of the backwave energy will escape through the port and cone, that is how a ported enclosure works, and I don't want that sound to be coloured by vibrating panels making the speaker sound boxy and woody. For the walls I use two ½" thick birch plys in a CLD construction with a flexible one-component marine adhesive sealant, with three ply layers for the baffle. I prefer the stiffness and "sound" of birch ply to MDF. This birch ply CLD, in addition to all the bracings in #3, adds enough stiffness and damping to make the cabinet dead enough. And I aim for a total mass of the cabinet 1200-1500 times the midwoofer's Mms, I don't want the midwoofer to be able to move the cabinet.

5. I always make the cabinet as deep as possible. In my experience, a midwoofer needs a minimum of 35cm distance to the cabinet's back wall. I don't know why but midwoofers always sound better in deep cabinets.

6. I always remember to test the finished loudspeaker using an amplifier with a high enough damping factor. It is easy to mistake an underdamped midwoofer/amplifier combo for a badly tuned ported loudspeaker. Even the world's best SET amplifier can make the world's best loudspeaker sounding like a boombox, if the two don't match. For SeasExcel/ScanspeakRevelator Qts 0,30-0,40 midwoofers with 7-8 cm2/gram Mms I prefer BJT amplifiers, by the way, these type of midwoofers need – and deserve – power!

So, that is my "handbook". It would be interesting to hear what others may think.

1. The first I do is to choose a midwoofer with Qts around 0,30 for standmounts and around 0,40 for floorstanders, that seems to be the sweet-spot. And for midwoofers I prefer motors with copper above and below the air gap (Seas Excel, Scanspeak Revelator), not inside the gap (Satori, Audio Technology, Wavecor). Midwoofers with copper inside the gap may sound superior in the midrange and in the lower treble, but I my opinion they lack punch and power in the bass and lower midrange. And I like the midwoofer's Mms to be no lighter/heavier than 7-8 cm2/gram, that is another sweet-spot that goes well with the Qts.

2. I then use some software to estimate the cabinet volume and port tuning, aiming for a system-Q around 0,70. The cabinet can be larger, but not smaller than 0,70. If space permits, I like the port area to be 30-35% of the midwoofers Sd. And I like to place the round(!) port on the front. The port opening inside the cabinet should be placed on a small baffel. The inside opening schould be placed in a golden ratio distance from the top and bottom of the cabinet.

3. And then the time consuming work begins. I know you can add stuffing inside the cabinet to balance the port response and to damp standing waves, this is a quick and easy fix but in my experience, the less damping inside the cabinet, the better. Lining the walls with ¼" wool felt is ok but even the slightest amount of volume stuffing almost always lead to a less lively and less open and less powerful loudspeaker. So I never stuff. Instead I build the cabinet with angled reflectors at the top and bottom, with lots of non-symmetrical shelf-braces in between, to break up the standing waves without choking the driver/port.

4. Most of the backwave energy will escape through the port and cone, that is how a ported enclosure works, and I don't want that sound to be coloured by vibrating panels making the speaker sound boxy and woody. For the walls I use two ½" thick birch plys in a CLD construction with a flexible one-component marine adhesive sealant, with three ply layers for the baffle. I prefer the stiffness and "sound" of birch ply to MDF. This birch ply CLD, in addition to all the bracings in #3, adds enough stiffness and damping to make the cabinet dead enough. And I aim for a total mass of the cabinet 1200-1500 times the midwoofer's Mms, I don't want the midwoofer to be able to move the cabinet.

5. I always make the cabinet as deep as possible. In my experience, a midwoofer needs a minimum of 35cm distance to the cabinet's back wall. I don't know why but midwoofers always sound better in deep cabinets.

6. I always remember to test the finished loudspeaker using an amplifier with a high enough damping factor. It is easy to mistake an underdamped midwoofer/amplifier combo for a badly tuned ported loudspeaker. Even the world's best SET amplifier can make the world's best loudspeaker sounding like a boombox, if the two don't match. For SeasExcel/ScanspeakRevelator Qts 0,30-0,40 midwoofers with 7-8 cm2/gram Mms I prefer BJT amplifiers, by the way, these type of midwoofers need – and deserve – power!

So, that is my "handbook". It would be interesting to hear what others may think.

Last edited by a moderator:

At 2500 Hz, the wavelength is 5.5 inches... That is a very reasonable crossover frequency for a midwoofer, and 5.5 inches is a very reasonable cabinet dimension, in fact most dimensions will be bigger... so I don't think we can dismiss standing wave concerns. Especially in the kind of cabinet that Animal Farm is describing, with minimal acoustical damping.

Very interesting set of guidelines. It seems you put a lot of thought into this.

I have never been happy with the bass from any ported speaker I made, probably because I used enough foam/fiber stuffing to get the midrange right and suppress the internal acoustic resonances. So fair to say, none of my boxes were anything like what you describe, and like I said, my results were disappointing. Optimizing ported bass response can be challenging, and your list may help people get it right with less trial and error...

j.

So, that is my "handbook". It would be interesting to hear what others may think.

Very interesting set of guidelines. It seems you put a lot of thought into this.

I have never been happy with the bass from any ported speaker I made, probably because I used enough foam/fiber stuffing to get the midrange right and suppress the internal acoustic resonances. So fair to say, none of my boxes were anything like what you describe, and like I said, my results were disappointing. Optimizing ported bass response can be challenging, and your list may help people get it right with less trial and error...

j.

Lots of anecdotes, but nothing in the way of facts, measurements or hard data. You preface your writings with "...for more than twenty-five years..." , an "Appeal to authority", Without hard data, you very well could be "doing it wrong" all this time. "Sounds right" just won't cut it these days.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------Rick....

------------------------------------------------------------------------------------------------------------------------------------------------------------------------Rick....

Last edited by a moderator:

Thank you for sharing. I allways like to hear about tech details.

I prefer closed box and especially fully stuffed TL, so I never bothered to make any classic BR speakers. But everything you wrote makes sense and goes along with my knowledge too.

Very good set of guidelines.

I prefer closed box and especially fully stuffed TL, so I never bothered to make any classic BR speakers. But everything you wrote makes sense and goes along with my knowledge too.

Very good set of guidelines.

I don't have anything even remotely close to planet10's level of speaker design expertise, but I'm scratching my head in confusion, too.I don’t know what to make of that recipe.

Lots of stuff i do not do.

dave

One thing I can say for sure: bigger ports are not always better.

By itself, the port/cab resonance tends to be very high Q, far too high for speaker use.

It is the driver (speaker) that has to produce the damping that controls the Q of the port, too.

A bigger port contains a larger mass of air. That larger mass takes more damping to control properly, just like a heavier car needs stiffer shock-absorbers to control its motion.

But the driver (speaker) has only so much damping to offer. If there is too much air in the (large diameter, long length) port, the end result tends to be a higher Q resonance from the port, i.e. "woofy" or "one-note" bass from the port.

At the other extreme, if the port is too small, air velocity in the port becomes too high, and you start to hear chuffing or wheezing sounds from the port when you turn up the volume.

Many decades ago, long before Thiele-Small and desktop computers and speaker simulation software, the advice in loudspeaker books was simply to make the ported enclosure as big as you could, then tune the port to the same resonance frequency as the speaker.

With a big enclosure, this might involve a very large port, and/or very short duct length (sometimes only the thickness of the wood itself). The "air spring" from a big box is softer, so to bring the port resonance frequency high enough, you end up needing a big port area.

That misguided recipe produced a lot of speakers with boomy, poorly controlled, one-note bass.

Very big enclosures, and very big port diameters, are not your friends if you want good bass performance from a bass-reflex speaker!

-Gnobuddy

Very interesting set of rules! The cabinet thickness point us very intriguing. I live the point about no stuffing for a port, it makes sense! You want it to be responsive not catching up.

Not interested in rebutting it point for point, but there is only a small fraction of that I agree with, and designs vary enough that, that percentage of agreement will very with different implementations but I wouldn't every expect it to be high.

I'd like to see some hi-res impedance measurements of midwoofer in a box like this vs free air impedance. Compasison like that could tell a lot.

1. The first I do is to choose a midwoofer with Qts around 0,30 for standmounts and around 0,40 for floorstanders

I look at the actual modeled curve to see if the driver meets those needs. Qts, Fs, Vas are a system, they have to be considered better.

Mms: there are so many interconnected factors/compromise this seems pretty silly.

Almost all floor stander 2-ways will actually be ML-TLs, or if you fight hard a BR/TL hybrid.

… copper inside the gap...

Flattens the drivers HF impedance. That will affect teh XO.

...aiming for a system-Q around 0,70...

Near butterworth, max flat when sealed, but what does that mean in a BR?

. the port area to be 30-35% of the midwoofers Sd.

Sd is pretty much irrelevant when we are talking about the box.

And I like to place the round(!) port on the front.

I m not huge fan of cylindrical duct vents. And where they go depends on so much else. The right answer is that it should go where it makes the most sense in the application.

The inside opening schould be placed in a golden ratio distance from the top and bottom of the cabinet.

Gobbledgook. Except for its irrationality, its connction to the fibonacci sequence, and its asethetic appeal, it really plays little role in a bass reflex.

But in your floorstander ML-TLs it needs to be carefully placed to get the response the designer would like. Like Zvent, Zd is even more important.

Your placement will help to minimize the TL response but how much depends on the Zd

3. … to a less lively and less open and less powerful loudspeaker.

A loudspeaker with more added resonances in the music. Some people like that. I prefer any resonances to be recorded in the software.

Damping in a loudspeaker is dependent on the design. A BR typically should have minimal damping or you start to play with the BR action. That is not necessarily a bad thing. My designs often do something akin, typically add extra R — damping — to the vents, pushing them more aperiodic. Internal volume fill tends to do the same thing.

So I never stuff. Instead I build the cabinet with angled reflectors at the top and bottom, with lots of non-symmetrical shelf-braces in between, to break up the standing waves without choking the driver/port.

4. ...don't want that sound to be coloured by vibrating panels making the speaker sound boxy and woody

Other than not knowing what woody means (in this context), an admiral goal. The less the cabinet radiates the lower its defraction signature. External shape also plays a role.

But CLD is hard to do properly and frankly overkill. But i do really like quality plywood, and dislike MDF.

...all the bracings in #3, adds enough stiffness and damping to make the cabinet dead enough.

I love bracing.

There are certain rules to optimize bracing, often not followed.

A brace DOES NOT make a dead box. A simple brace divides a panel into 2 shorter subpanels which resonant. If those )potential) resonances can be pushed above the bandwidth of the driver playing in that box it does effectively make it non-resonant. This is a very useful trick in a woofer.

5. I always make the cabinet as deep as possible.

One can go too far. Having the sides too close is just as bad.

6. I always remember to test the finished loudspeaker using an amplifier with a high enough damping factor.

Damping factor is a marketing term. Now most modelers, and most commercial loudspeaker designers assume a low Rout amplifier. But many of those that hang out here know that there is a much richer world out there, a much bigger design space, if one does not limit oneself to low Rout amplifiers. Take for example all the SETs/SEPs/bridged ACA, F1, F2, more...

If you tested any of these with a low Rout amplifier they would not work right.

http://wodendesign.com/downloads/King-of-Swingers.pdf

If the speaker was designed for a high Rout it should be tested with such. Loudspeaker, amplifier, and wha connects them is a system.

No, the reason the speaker is boomy is because the designer did not design the loudspeaker for that amplifier.Even the world's best SET amplifier can make the world's best loudspeaker sounding like a boombox

Mr. Farm has painted himeself into a very small portion of the huge design space available to DIYers. There are good bits amoungst a bunch of oversimplification or outright misleading statements.

But as long as he is happy when istening in his chair all is fine, just don’t go to him for well thot out design tips.

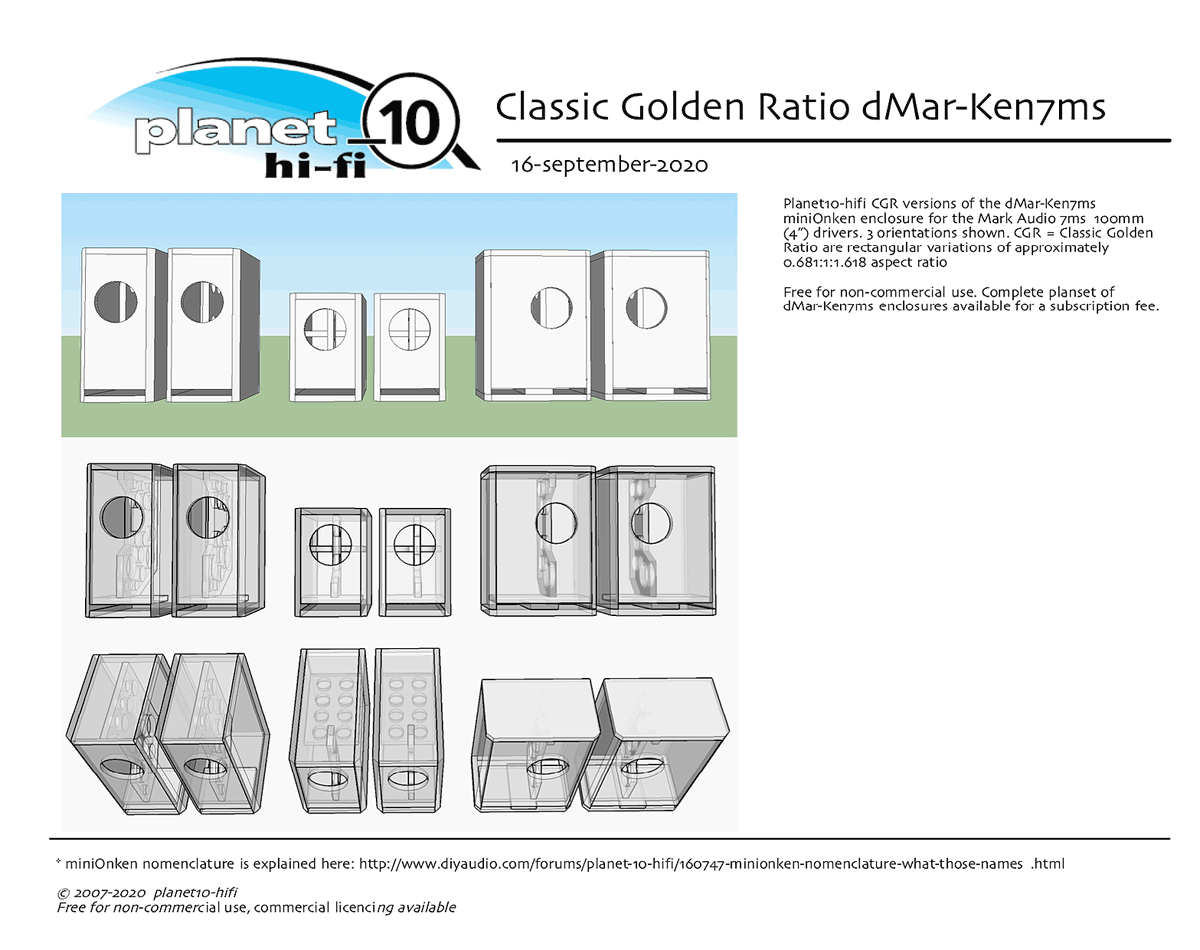

And as an aside ireally like the golden ratio (these are 9L, i have simialr sized from 2.5 to 35 litres):

dave

An interesting question is, how is the port in a loudspeaker different from an organ pipe? Both are pipes full of air. Both have exactly the same physics, and are described by the same mathematical equations of wave motion inside a pipe.I live (like)the point about no stuffing for a port, it makes sense! You want it to be responsive not catching up.

The organ pipe has a strong resonance at one frequency. To use your words, it is very responsive - but only at its resonant frequency.

But we want the speaker port not to do this. We don't want "one note bass" from the port. We want it to respond roughly equally over a range of frequencies instead.

The only way to avoid "one note bass" is to add damping - lots of damping - to the port. The Q of the port resonance has to be lowered a lot, so that it can augment the driver, but not take over and dominate the bass response of the speaker. We have to make it LESS responsive.

In other words, we want lots of damping at the port. Without damping, it is TOO responsive, like an organ pipe. With the right amount of damping, it does what we want. We want just the right amount of responsiveness, not too much!

The traditional solution is to design the speaker (driver), box, and port so that damping built into the driver also provides the necessary damping for the port. If the design is done properly, it works very well. The speaker's own damping controls air motion in the port, and you get nice extended bass without "one note bass" problems.

An alternative way is to add some additional damping at the port itself. This is not modeled in the original Thiele-Small paper, as far as I know. But these days with powerful computers and easy simulation software, it's not hard to model the effect of damping added to the port. Even a layer of very thin fabric across the mouth of the port adds significant damping, because air is moving fast there.

Stuffing a port full may render the port useless (too little air movement). But just the right amount of damping in the port is not automatically a bad thing.

Also: personally, I think an overstuffed (and useless) port is better than "one note bass" from a too-responsive port! Of the two errors, an overdamped port is the lesser of the two evils.

-Gnobuddy

Exactly what i do. One has to get to know what the vent with higher R does to the LF response. I am looking for a specific shape roll-off curve that will respond nicely once the R is factored in.An alternative way is to add some additional damping at the port itself. This is not modeled in the original Thiele-Small paper

How much you add R, is a compromise. One has to make the compromises that make the most sense in the context of the application.

dave

The organ pipe is usually closed on one side.An interesting question is, how is the port in a loudspeaker different from an organ pipe? Both are pipes full of air.

Without knowing the exact physics i know that a pipe with one closed side resonates much stronger than an open one.

You are still right, there are port resonances but much higher frequency than helmholtz resonance of the system.

Helmholtz resonance does not use the port resonance but the weight of port air in combination with enclosure spring-load.

A closed pipe (or open at both ends) is a half-wave resonator, open at one end is quarter-wave.

Stronger does not apply.

dave

Stronger does not apply.

dave

Agreed!Stronger does not apply.

I probably was too focused on an actual organ pipe (or pan flute) where the closed pipe creates more "turbulent" resonance when blown with an air stream.

I was curious about the Mms requirement

So I looked at a couple of woofers with Qts in the range of what Animal Farm likes. Only the ScanSpeak is in the range (approximately), but all these woofers work well as bass drivers. So I am not sure I agree with this requirement.

And I like the midwoofer's Mms to be no lighter/heavier than 7-8 cm2/gram, that is another sweet-spot that goes well with the Qts.

So I looked at a couple of woofers with Qts in the range of what Animal Farm likes. Only the ScanSpeak is in the range (approximately), but all these woofers work well as bass drivers. So I am not sure I agree with this requirement.

I my opinion, Seas Excel W15/W16/W18 magnesium and Scanspeak 15WU/8545/18WU paper are all examples of midwoofers well suited for ported two-way loudspeakers, with Qts around 0,30-0,40 and cm2/gram around 7-8. and they all sound very good.

I think Michael Fremer, Stereophile, once wrote: "There is no sure recipe for successful loudspeaker design. No matter how much science we throw at loudspeaker design, in the end it will remain, like the building of musical instruments, an art."

And that is the beauty of this hobby and what that makes it so fascinating for DIYers. We all have our preferences, and I have just shared some of mine.

I think Michael Fremer, Stereophile, once wrote: "There is no sure recipe for successful loudspeaker design. No matter how much science we throw at loudspeaker design, in the end it will remain, like the building of musical instruments, an art."

And that is the beauty of this hobby and what that makes it so fascinating for DIYers. We all have our preferences, and I have just shared some of mine.

- Home

- Loudspeakers

- Multi-Way

- How to build the perfect ported cabinet. ...