As part of a woodworking forum I asked an opinion of what a slot/dado would do to help a cabinet vs just glue. Of thos who replied, a glued joint is as strong or stronger than MDF itself. The tritrix has slots cut appx 1/4" into the sides for the TL divider to fit into. The corner waveguides do as well. So My question is of how important is this joint if the divider is well glued and clamped just to the surface. Also, the slot/dado does not run the full length of the TL. Both ends have appx 4 to 5 inches that come up out of the slot/dado and glue to the surface.

The search feature here turns up threads with hundreds of pages and no way that I know of to find the exact info so I am asking this in here as well.

.

.

The search feature here turns up threads with hundreds of pages and no way that I know of to find the exact info so I am asking this in here as well.

.

.

Attachments

We know that usually a butt joint is minimally sufficient, and the glue will hold until the wood gives. With certain types of wood, a dado gives a greater area to glue as well as a range of grain aspects, and a mechanical advantage.

So which is the weakest, how will this help MDF? It seems that if you stress a butt joint it is most likely to come undone by delaminating the MDF on the glued surface. By creating a more involved joint you're ensuring a larger portion of the thickness is taking the stress.. on both pieces, if the right joint is selected.

So which is the weakest, how will this help MDF? It seems that if you stress a butt joint it is most likely to come undone by delaminating the MDF on the glued surface. By creating a more involved joint you're ensuring a larger portion of the thickness is taking the stress.. on both pieces, if the right joint is selected.

Thank you very much for the help, that tells me the dado joint is for structural and not audio purposes.

Donny

Donny

For what reason do you feel this is less suitable? Audio calls for many things in a box but one is that it doesn't flex needlessly. A mitre joint is also interesting but many avoid it because it requires precision cuts.

Hey Donny

You are over thinking that cabinet. The dado lets you get the parts in the right place every time. I made those speakers and the cabinets were very solid. Good glue joints (spread the glue evenly and clamp) will be much stronger than needed. I have woofer boxes that I made in the early 90's with MDF and butt joints that are still rock solid.

I do use dados in my recent builds because it helps me ensure the box is square and all the panels end up where I wanted them. My most recent build was a set of microtowers with mostly butt joints and while they are plenty strong I cursed loudly at not having the dados for alignment on the longer joints.

You are really going to like those speakers. They are a great introduction to DIY.

You are over thinking that cabinet. The dado lets you get the parts in the right place every time. I made those speakers and the cabinets were very solid. Good glue joints (spread the glue evenly and clamp) will be much stronger than needed. I have woofer boxes that I made in the early 90's with MDF and butt joints that are still rock solid.

I do use dados in my recent builds because it helps me ensure the box is square and all the panels end up where I wanted them. My most recent build was a set of microtowers with mostly butt joints and while they are plenty strong I cursed loudly at not having the dados for alignment on the longer joints.

You are really going to like those speakers. They are a great introduction to DIY.

Thanks everyone for your help,

Allen, thanks for helping. Precision cuts are common for woodworkers. Such as the required 78° TL, easy peasy to a woodworker. We sometimes get anal about thousandths of blade alignment tolerance. Glue and wood/MDF is very strong, the point of the glue/mdf contact is not going to move. It appeared the slot was for ease of kit assembly but I wasn't sure. Add to all of this are the screws which I personally add a small amount of glue to the screw holes to help strengthen the fibers long term (not to much or it will cause a bulge). I question what happens when the TL comes up out of the dado to lay on top of the MDF. Appx 4 inches on each end is not in the slot, is this transition perfect? So I questioned whether the dado was actually acoustically important, thus my thread. I wasn't questioning strength just acoustics.

Thanks Signal lost, I appreciate the help.

P.S. I don't care for miters, I prefer half laps, lock joints and box/finger joints. If I miter for appearence I will also reinforce with splines.

Allen, thanks for helping. Precision cuts are common for woodworkers. Such as the required 78° TL, easy peasy to a woodworker. We sometimes get anal about thousandths of blade alignment tolerance. Glue and wood/MDF is very strong, the point of the glue/mdf contact is not going to move. It appeared the slot was for ease of kit assembly but I wasn't sure. Add to all of this are the screws which I personally add a small amount of glue to the screw holes to help strengthen the fibers long term (not to much or it will cause a bulge). I question what happens when the TL comes up out of the dado to lay on top of the MDF. Appx 4 inches on each end is not in the slot, is this transition perfect? So I questioned whether the dado was actually acoustically important, thus my thread. I wasn't questioning strength just acoustics.

Thanks Signal lost, I appreciate the help.

P.S. I don't care for miters, I prefer half laps, lock joints and box/finger joints. If I miter for appearence I will also reinforce with splines.

Last edited:

I like your idea of glue on the screws. In my model airplane builds the screw threads are often hardened with CA.

How are you planning to finish the cabinets?

How are you planning to finish the cabinets?

I expect the speaker grill kit, magnets and black cloth to arrive today or tomorrow. I want to paint it a deep/dark maroon and have a bloodwood bottom stand. I am learning HVLP spraying as well and have tried my best to find a suitable primer. I bought Zinsser Bin primer shellac but I am still looking and learning. It will probably be safe to go with an oil based paint but am stumped trying to find an MDF, HVLP, Laquer friendly base coat, any ideas?? Isloators are more expensive than kidneys!! I am probably not going to go that fancy for my first speaker build, Maybe a DIY neopreme something.

What do you suggest for paint?? And thanks again for helping. Are your models powered ?? After reading my original thread I did first post this as a structural thing, sorry the confusion.

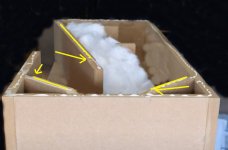

Pic of wood in a minute or 2

What do you suggest for paint?? And thanks again for helping. Are your models powered ?? After reading my original thread I did first post this as a structural thing, sorry the confusion.

Pic of wood in a minute or 2

Attachments

Last edited:

Most of my models are electric with one or two discus launch gliders. When I started with electric power many years ago the others at the field thought I was off my rocker. Then I became the Guru.

Finishing is my weakness. So follow this advise at your peril. Those cabinets sucked up a lot of paint and still look poor. I bought the same primer for the next MDF cabinet but I have not opened the can. Instead I have been using Dura tex or veneer on MDF and Baltic Birch for other cabinets. The dura-tex is so simple just roll in on bare MDF an let it cure. Often even with a veneered cabinet I will dura tex the baffle. If I did those Tri Trix again I might veneer the sides and Dura tex the rest. For isolators are you talking about feet? I used feet for guitar amps and cabinets from parts express about 2 bucks a speaker. For pre-amps and other things I use feet from Isolate it.

Finishing is my weakness. So follow this advise at your peril. Those cabinets sucked up a lot of paint and still look poor. I bought the same primer for the next MDF cabinet but I have not opened the can. Instead I have been using Dura tex or veneer on MDF and Baltic Birch for other cabinets. The dura-tex is so simple just roll in on bare MDF an let it cure. Often even with a veneered cabinet I will dura tex the baffle. If I did those Tri Trix again I might veneer the sides and Dura tex the rest. For isolators are you talking about feet? I used feet for guitar amps and cabinets from parts express about 2 bucks a speaker. For pre-amps and other things I use feet from Isolate it.

Going back to glue, urethane glue is insanely strong on mdf it will not break at the glue joint, and if you dampen it first it will expand and fill any voids. However it does require clamping and you MUST scrape it off before it fully hardens as it is a bear to sand. For finish on mdf I tried shellac it seals the grain pretty good but is difficult to get other paint to adhere to it. My preference is paper backed veneer used with heat bond contact cement if you can live with the very fine line it leaves. If you have the time a lacquered finish looks good but are not as durable as urethane finishes.

Bill

Bill

FYI, plain old PVA (yellow) wood glue is stronger in shear than urethane - just doesn't fill gaps as well. (Check an article in FineWoodworking). Don't use latex paint as a first coat on MDF. The water base of latex will be absorbed and the MDF will swell. Shellac - couple coats - or an oil based primer is best, then follow w with latex if you want.

Thanks everyone,

I have the bins shellac waiting for it. My joints are very tight and screwed as well and when you put a knuckle to it the sound is very tight. I have learned a lot from the people here and building the cabinet myself, I appreciate all the help.

I am now comfortable without dados as long as the cuts are straight, square, well glued and screwed ( I clamped and cauled at times as well). When I set up to cut the baffles, waveguides, braces and panels at 6", I cut them all at the same time and they were the same exact height.

.

.

I have the bins shellac waiting for it. My joints are very tight and screwed as well and when you put a knuckle to it the sound is very tight. I have learned a lot from the people here and building the cabinet myself, I appreciate all the help.

I am now comfortable without dados as long as the cuts are straight, square, well glued and screwed ( I clamped and cauled at times as well). When I set up to cut the baffles, waveguides, braces and panels at 6", I cut them all at the same time and they were the same exact height.

.

.

Attachments

Last edited:

When you rap the edges with your knuckles the sound will be short compared to the middle of the panel, helping you to know where most movement is.

Thanks Allen for the reply. The lowest tone comes from the area farthest from any support, the area between the braces behind the drivers, but maybe it is suppose to be a little "boomy" there.

- Home

- Design & Build

- Construction Tips

- Slots and Dados vs just glue?