Moderator note: Thread title changed at OP's request.

THIS THREAD CHANGES FROM YUCHI A290 HORN TO AN 18SOUND XT1464. FOLLOW Moded 2226H + 2451J on XT1464

Hello again guys. I had a great project going in the fullrange section, a B&W teardrop shape with Fostex 168 drivers. As life has it, something came inbetween. After a long time, wanted to go back to the project and finaly finish it.... When I pulled the enclosures out of a dry storage, they have been badly cracked. That was the second time when translam didnt work (wesayso had same problem). And in the bin they went, sadly.

Now.....new project 😀 Currently Im having a CAD program done for the famous Yuichi A290 horn, so that it can be machined on a CNC router. Found a guy in my country *central Europe) who would be willing to make them. You can find them on ebay and such, but still over 1.000 dollars for a pair. I wanna push the price way way lower. Once I got the CAD file, I will bargain with the CNC company to have them made. As a compensation for good price, I would like to know if anyone else would be interested in a pair. I do not promise this, but I think we could get it down to 600 per pair...depends on the amount of horns he will make.

Danny

Last edited:

Hi Dave 🙂

I do have the plans from Yuichis site. Not sure about the legal issues giving out plans which Im paying for. Maybe you can help....

Danny

I do have the plans from Yuichis site. Not sure about the legal issues giving out plans which Im paying for. Maybe you can help....

Danny

Make for yourself is fine. Make to sell is not fine. Pretty sure this is stated of his web page. Sometimes we don't look well enough for things we don't want to find.

puppet - I dont want to make money of it. I am paying for the CAD files, and routing job. More then happy to share with fellow DIYers...If it works out, I can be the middle man to have the horns made for others, no charge for me, except if I have to pick them up (gass money), or have to ship them (which is normal). I just want to "spread the love" so to say 😀 😀 😀

Oh, I see, my mistake. The fella making yours will make a pair for me, free of charge.

I'll take a half dozen. Let me know when they're shipping, OK?

I'll take a half dozen. Let me know when they're shipping, OK?

Only the original drawings are copyright. Any redo of the drawings is copyright of the artist (or who he assigns them to).

Having something that a CNC can use would be very useful. If the CNC has enuff z you shoud be able to do at as an upper & lower half, plus the vanes.

I ask because as soon as i get the new dongle for my CAD software i was going to takle this exact drawing. But no sense in doing it twice. I already have a 1st order approximation of the horn drawn.

When i get my CAD straightened out i’ll look at neskor’s drawing.

dave

Having something that a CNC can use would be very useful. If the CNC has enuff z you shoud be able to do at as an upper & lower half, plus the vanes.

I ask because as soon as i get the new dongle for my CAD software i was going to takle this exact drawing. But no sense in doing it twice. I already have a 1st order approximation of the horn drawn.

When i get my CAD straightened out i’ll look at neskor’s drawing.

dave

No, he wont make you a free pair or dozen....why do you have to write that? You know what I mean. Im not here to make money, Im writing this to convince the manufacturer to make more of them, for a fair price, like a group buy. I get a pair for a good price, and somebody else, who wants a pair, also.....Jesus And anyway, your from US, why would you wont a pair? Shipping would kill you. Are you trolling me?

He's trolling. Just ignore.

So, this would be a group buy ?

I may be able to help with cad files. I'll check with a guy i know made A290 on his cnc.

So, this would be a group buy ?

I may be able to help with cad files. I'll check with a guy i know made A290 on his cnc.

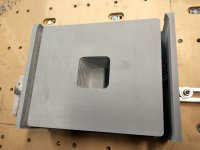

Yes. Throats have the smoothest transition from square to circle i have seen so far.

Attachments

Last edited:

Oh, I see he modified the throat adaptors to use the TAD 4002z drivers, which are 1.5". That's cool - hopefully he calculated the expansion properly, to maintain the same Fc = 290Hz and T = 0.7 as the horn itself.

Yes like a group buy. I just have to get a pair made and see how much he will charge me. Ive asked him for a price esrimate from solid hardwood, birch ply and HDF as a budget option. Once He has the process nailed, he can let me know the price for a batch manufacturing

Danny

Danny

He's trolling. Just ignore.

So, this would be a group buy ?

I may be able to help with cad files. I'll check with a guy i know made A290 on his cnc.

Thanks for the offer. I have a guy working on the cad files. I dont want to use somebody elses plqns withou his consent. It take a lot of time to make them, dont wanna be a leach on somone elses work 🙂

So I was able to create a 3D exported file from Sketchup, easily opened in 3D Print program in Windows. Looks bloody good if I say so my self 🙂 now off to the manufacture with it (he requested specific file type for his CNC router) which I was able to do with this easy to use 3d program.

Ill let you know, if he accepts the file. What Im afraid of is the polygons instead of a perfect circle, might mean there will be some sanding involved.

Also I went for a horn with straight and curved sides, dont know which one is it, but the first part is straight, and close to the throat its curved, same as TAD TH4001. The curve in horizontal (sides) is within 5% of the original plan, curve in the vertical (top and botom pieces) is within 6%, my best guesstimate. I dont think Yuichis measurement with hand on a finished TH4001 were that precise, some margin for error sure must be included.

Anyway, hopefully the manufacturer will be able to make me a mockup from foam first. Then comes the wood model.

Danny

Ill let you know, if he accepts the file. What Im afraid of is the polygons instead of a perfect circle, might mean there will be some sanding involved.

Also I went for a horn with straight and curved sides, dont know which one is it, but the first part is straight, and close to the throat its curved, same as TAD TH4001. The curve in horizontal (sides) is within 5% of the original plan, curve in the vertical (top and botom pieces) is within 6%, my best guesstimate. I dont think Yuichis measurement with hand on a finished TH4001 were that precise, some margin for error sure must be included.

Anyway, hopefully the manufacturer will be able to make me a mockup from foam first. Then comes the wood model.

Danny

Last edited:

First STL 3D model

Little teaser....

Hope it displays correctly

Danny

Little teaser....

Hope it displays correctly

Danny

An externally hosted image should be here but it was not working when we last tested it.

Following, trying to figure out if it is practical and if so how get a pair of the A-290 made here. Knocked down CNC'd parts might not be too bad to ship. (Final assembly done by the buyer.)

- Home

- Loudspeakers

- Multi-Way

- Moded 2226H + 2451J on XT1464