Few weeks ago I encountered a Sonab speaker (I think it was a OA5) fitted with a Philips M9710 driver, the back of the driver covered with a basked lined with damping material.

Photos from Troels Gravensen website here.

Photos from Troels Gravensen website here.

Troels descibes the purpose of this construction.

To keep it simple I just covered the back of the driver with gaffa tape.

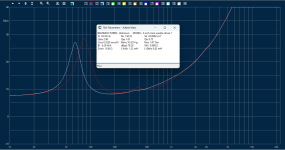

And measured again the TS parameters and impedance. Red is driver impedance, White driver impedance with added mass (7 gram)

Effects:

I repeated the experiment with masking tape instead of gaffa tape. The result was essentially the same. To illustrate the effect of these changes I simulated a closed box with Basta:

Box 2ltr

GHP C=1200uF

Viso=80%

Qb=20

driver no tape Fs (-3dB) = 103Hz, Eff 81,2dB

driver with tape Fs (-3dB0 = 80Hz, Eff. 80,3dB

So for a loss in efficiency of about 1dB we can lower the Fc of the speaker from 103Hz --> 80Hz. The effect seems to be caused by the added mass due to the air enclosed between the cone and tape, and the added resistance to the air moving.

The method used by Sonab seems to be a way to control the effect.

Troels descibes the purpose of this construction.

I remember having seen similar constructions in fifties and sixties radio's. Seeing it again made me curious, so I did a small experiment using a pair of mini 3 inch woofers (originally from a pair of Peaq PC speakers). I measured the TS parameters, shown right.the 9710 driver placed in a metal mesh basket with some heavy glassfiber material between driver and mesh, making a low-pass filter that can be adjusted due to the basket being suspended on three screws that allows you to increase or decrease the acoustic resistance of the fiber material. An acoustic vent, sort of. Something similar can be found on some Lowther drivers.

To keep it simple I just covered the back of the driver with gaffa tape.

And measured again the TS parameters and impedance. Red is driver impedance, White driver impedance with added mass (7 gram)

Effects:

| Parameter | No damping | With damping |

| Fs | 91,5 | 83,5 |

| Qms | 4,18 | 3,11 |

| Qes | 1,0 | 0,87 |

| Qts | 0,72 | 0,76 |

| Cms | 0,383 | 0,333 |

| Rms | 1,09 | 1,84 |

| Bl | 6,24 | 6,55 |

| dBspl | 81,4 | 79,0 |

| Vas | 0,99 | 0,86 |

| Mms | 7,9 | 10,9 |

I repeated the experiment with masking tape instead of gaffa tape. The result was essentially the same. To illustrate the effect of these changes I simulated a closed box with Basta:

Box 2ltr

GHP C=1200uF

Viso=80%

Qb=20

driver no tape Fs (-3dB) = 103Hz, Eff 81,2dB

driver with tape Fs (-3dB0 = 80Hz, Eff. 80,3dB

So for a loss in efficiency of about 1dB we can lower the Fc of the speaker from 103Hz --> 80Hz. The effect seems to be caused by the added mass due to the air enclosed between the cone and tape, and the added resistance to the air moving.

The method used by Sonab seems to be a way to control the effect.

Attachments

This is not the expected behaviour. Was this observed, or perhaps just speculation?making a low-pass filter that can be adjusted due to the basket being suspended on three screws that allows you to increase or decrease the acoustic resistance of the fiber material.

Pure nonsense, these are old dust covers.

The cloth on the back of the speaker is = absorption material

Being directly on the back of the driver is similar to lining a cabinet with absorption material.

Pressure needs to pass through it.

Troels is also full of crap.

Older speakers used these dust covers, the added benefit was slight absorption directly on the back of the cone.

Duct tape or masking tape is creating a leaky enclosure.

The impedance curve would be completely opposite.

Fs will raise in a enclosure.

They look cool I think, keeps dust and debris out of coil for old open back radio speakers.

Many or most were still electro magnets/ field coil with bucking coils.

Something open baffle heads could use to look interesting and offer very very slight absorption

The cloth on the back of the speaker is = absorption material

Being directly on the back of the driver is similar to lining a cabinet with absorption material.

Pressure needs to pass through it.

Troels is also full of crap.

Older speakers used these dust covers, the added benefit was slight absorption directly on the back of the cone.

Duct tape or masking tape is creating a leaky enclosure.

The impedance curve would be completely opposite.

Fs will raise in a enclosure.

They look cool I think, keeps dust and debris out of coil for old open back radio speakers.

Many or most were still electro magnets/ field coil with bucking coils.

Something open baffle heads could use to look interesting and offer very very slight absorption

Last edited:

You just overcomplicated it. Cover must be breathable - no gaffa or masking tape! Try with thin felt.To keep it simple I just covered the back of the driver with gaffa tape.

If it is a thin fabric, it is dust cover only. If it is a thicker felt, it will change somewhat Thiele-Small parameters of the driver.