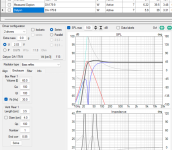

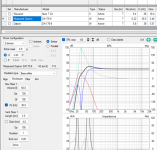

So either this data is junk or Dayton woofers are REALLY off spec. I am inclined to believe either as I've both messed up measurements and had Dayton woofers that measured no where close to their specs.

I took impedence measurements of 3 of woofers (should have been 4 but one arrived damaged). They all measured nearly identically. I measured these exactly the same as I have measured every other woofer I have ever used. Unless I royally screwed something up. I'll even zip the impedence measurements and toss them on here.

The one spec I find the most concerning is the MMS. They have listed 24.17 grams. I show 16.27 grams. Way off. I used 12.08 grams of blue tack and added that to the cone for my measurement. That should have been half of the MMS. If the MMS is actually 24.17 grams.

Can anyone see errors in my measurements here? Or is this just what it is?

I might just buy a DATS V3 just so I can always be sure. Thoughts on how good those units are? Pretty reliable?

I took impedence measurements of 3 of woofers (should have been 4 but one arrived damaged). They all measured nearly identically. I measured these exactly the same as I have measured every other woofer I have ever used. Unless I royally screwed something up. I'll even zip the impedence measurements and toss them on here.

The one spec I find the most concerning is the MMS. They have listed 24.17 grams. I show 16.27 grams. Way off. I used 12.08 grams of blue tack and added that to the cone for my measurement. That should have been half of the MMS. If the MMS is actually 24.17 grams.

Can anyone see errors in my measurements here? Or is this just what it is?

I might just buy a DATS V3 just so I can always be sure. Thoughts on how good those units are? Pretty reliable?

Attachments

Last edited:

Measurements usually give a conistent set of parameters that will provide very similar enclosure simulations to data sheet or other measurements, even if the parameters themseves vary. That's usually no problem.

Did you loosen up the suspension prior to measurement?

Have a look at this driver test and the (apparent) parameter deviation:

https://hificompass.com/en/reviews/seas-excel-6-w18nx003-e0096-08-midwoofer-review

Make sure to click on the hidden paragraph "Broken-in and measurements of Thiele-Small parameters by other manufacturers"!

Did you loosen up the suspension prior to measurement?

Have a look at this driver test and the (apparent) parameter deviation:

https://hificompass.com/en/reviews/seas-excel-6-w18nx003-e0096-08-midwoofer-review

Make sure to click on the hidden paragraph "Broken-in and measurements of Thiele-Small parameters by other manufacturers"!

Member

Joined 2003

The measurements are quite noisy, that could be one source of error in T/S determination. Added mass is barely managing 25% drop in Fs, I would use a bit more added mass personally. You should also start your measurement sweep at 0Hz, not 20Hz, there's a lot of missing information that REW is trying to fill in with a curve fitting algorithm.

Comparison to datasheet is inconsequential - datasheets are often wrong. Comparison to actual result when the driver is placed in a cabinet is what matters.

Comparison to datasheet is inconsequential - datasheets are often wrong. Comparison to actual result when the driver is placed in a cabinet is what matters.

Yeah, broke them in for a good 18 hours. Was warm in the shop so the drivers were not cold.Did you loosen up the suspension prior to measurement?

I did notice that. I looked through some of my old measurements and found that a decent portion of my ZMA measurements are quite noisy. They didn't effect the TS measurements like this but agreed, not great measurements. Hence me considering just buying the DATS.The measurements are quite noisy,

FWIW, the pioneers QA was close tolerance to its efficiency, which at 84.43 is 99.3% of 85 'says' good enough for me.So either this data is junk or Dayton woofers are REALLY off spec.

FWIW, in ignorance chose to add between 1.44 - 1.56x and always got the predicted results close enough for me and the intended owner:Added mass is barely managing 25% drop in Fs

Pg. 76: https://archive.org/details/HowToBuildSpeakerEnclosuresByAlexixBadmaieffDonDavis/page/n75/mode/2up

“A nagging question in the design stage of any enclosure of this type is "How large shall it be?” It was pointed out earlier that the enclosure can be too large or too small for proper bass-reflex action. This implies that an optimum volume exists and indeed it does. This optimum volume does not depend upon the size of the speaker nor its resonant frequency per se but rather on the ratio of enclosure air stiffness to the speaker cone suspension stiffness. This optimum ratio is 1.44 or, looking at it another way, the speaker resonant frequency in the enclosure before porting should be 1.56 times the free-air resonance of the speaker. This size enclosure, when properly tuned, yields at the same time the most extended low-frequency response and a transient response with subjectively unnoticeable hangover, assuming sufficient damping exists. Compared to the entirely closed cabinet, the half-power point (3 db down) occurs at 0.7 times the closed cabinet speaker resonance for an extension of one-half octave."

Member

Joined 2003

It provided the correct compliance, so seemed reasonable that when T/S came along that its Vas spec measurement would be most accurate.

It's not a problem, whatever you believe to be the problem.

Make adjustments to cabinet size to compensate.

You could have bought Scan Speak and felt the same.

Make adjustments to cabinet size to compensate.

You could have bought Scan Speak and felt the same.

Mms is cross calculated with Mmd and.....Mdl

So I am sure Dayton knows the moving mass of the parts and far as Mdl radiation mass of air load.

Im sure is susceptible to all kinds of errors to home measurements.

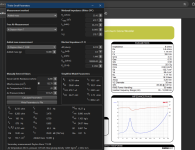

I have sum checked and entered likely every driver Dayton makes in virtuix or WinIsd

WinIsd has sum check error when you enter data. If any conflictions it tells you right away

and wont let you save the driver. And will tell you what parameters have conflictions.

I have never had any sum check or glaring errors with any Dayton drivers.

So hardly doubt their T/S parameters are wrong.

Actually had way way more errors with more " expensive" drivers

Just enter DS175 into sim and press calculate.

Magnet is extremely powerful with Low Qts. Without simulating 9 out of 10 guesses

will be it is a 4th order alignment. So either BB4 or C4 hit calculate and done.

So I am sure Dayton knows the moving mass of the parts and far as Mdl radiation mass of air load.

Im sure is susceptible to all kinds of errors to home measurements.

I have sum checked and entered likely every driver Dayton makes in virtuix or WinIsd

WinIsd has sum check error when you enter data. If any conflictions it tells you right away

and wont let you save the driver. And will tell you what parameters have conflictions.

I have never had any sum check or glaring errors with any Dayton drivers.

So hardly doubt their T/S parameters are wrong.

Actually had way way more errors with more " expensive" drivers

Just enter DS175 into sim and press calculate.

Magnet is extremely powerful with Low Qts. Without simulating 9 out of 10 guesses

will be it is a 4th order alignment. So either BB4 or C4 hit calculate and done.

- Home

- Loudspeakers

- Multi-Way

- Why is the MMS so far off?