I am working on a gift for my father-in-law. looking for advice on bass alignment.

I have previously built the speakers you can see in this thread https://www.diyaudio.com/community/threads/3-way-w-sb-acoustics-ceramics-woofer-choice.348896/

My design is for an approximate 0.5 ft3 or 15 L box with a SB17 woofer and SB26 tweeter in a 6" elliptic waveguide.

Have the choice narrowed down between 2 passive radiators, or a 2" port.

1. Passive Radiator: SB15SFCR-00

https://www.madisoundspeakerstore.c...b-acoustics-sb15sfcr-00-5x8-passive-radiator/

Very similar to what I see used on commercial speakers with a 6" woofer. The F3 I am seeing is a bit higher than I would like, but my in-laws are by no means bass heads.

F3 51.1 Hz, F6 43.0 Hz, F10 37.2 Hz

2. Passive Radiator: SB20PFCR-00

https://www.madisoundspeakerstore.c...acoustics-sb20pfcr-00-passive-radiator-round/

With this I get a deeper extensions, but the moving mass is quite high. Having not worked with passive radiators before will this lead to "slow" response.

F3 46.9 Hz, F6 40.0 Hz, F10 35.1 Hz

3. Ported: 2" flared port

No surprises here, just an 8" or 20cm flared port.

F3 45.6 Hz, F6 38.9 Hz, F10 33.2 Hz

I have some desire to use a passive over a port as placement will not be ideal and it could be fun to do something different. Perhaps this is all moot if I decide to cross a sub at 80-120 Hz.

Details that will help guide advice. These will be placed on a large TV console. It is low and fairly deep, speakers would be about 12" from the back wall. Console is probably 96" wide. The room has a horrid echo, stone floors and ceiling height stone on the kitchen at the side. My in-laws live in Shanghai, so will be hand delivering the speakers my next visit. Will buy the electronics (integrated amp) when I am there. May also get a reasonable 12" powered sub as the room is quite large (estimate 18 ft by 40 ft).

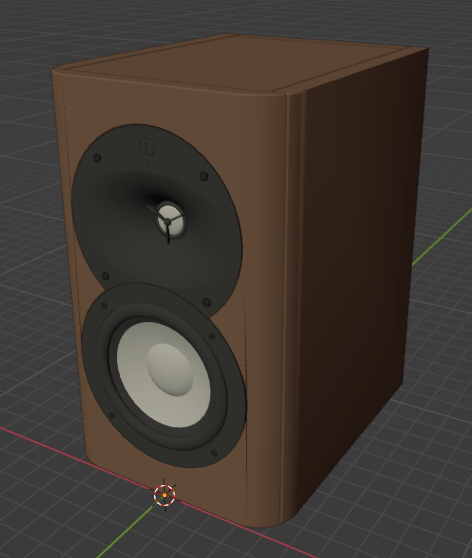

Picture of design concept:

I have previously built the speakers you can see in this thread https://www.diyaudio.com/community/threads/3-way-w-sb-acoustics-ceramics-woofer-choice.348896/

My design is for an approximate 0.5 ft3 or 15 L box with a SB17 woofer and SB26 tweeter in a 6" elliptic waveguide.

Have the choice narrowed down between 2 passive radiators, or a 2" port.

1. Passive Radiator: SB15SFCR-00

https://www.madisoundspeakerstore.c...b-acoustics-sb15sfcr-00-5x8-passive-radiator/

Very similar to what I see used on commercial speakers with a 6" woofer. The F3 I am seeing is a bit higher than I would like, but my in-laws are by no means bass heads.

F3 51.1 Hz, F6 43.0 Hz, F10 37.2 Hz

2. Passive Radiator: SB20PFCR-00

https://www.madisoundspeakerstore.c...acoustics-sb20pfcr-00-passive-radiator-round/

With this I get a deeper extensions, but the moving mass is quite high. Having not worked with passive radiators before will this lead to "slow" response.

F3 46.9 Hz, F6 40.0 Hz, F10 35.1 Hz

3. Ported: 2" flared port

No surprises here, just an 8" or 20cm flared port.

F3 45.6 Hz, F6 38.9 Hz, F10 33.2 Hz

I have some desire to use a passive over a port as placement will not be ideal and it could be fun to do something different. Perhaps this is all moot if I decide to cross a sub at 80-120 Hz.

Details that will help guide advice. These will be placed on a large TV console. It is low and fairly deep, speakers would be about 12" from the back wall. Console is probably 96" wide. The room has a horrid echo, stone floors and ceiling height stone on the kitchen at the side. My in-laws live in Shanghai, so will be hand delivering the speakers my next visit. Will buy the electronics (integrated amp) when I am there. May also get a reasonable 12" powered sub as the room is quite large (estimate 18 ft by 40 ft).

Picture of design concept:

I've been entertaining the idea to use a PR also, but was held back by the same doubts/questions. I'll follow this thread, hopefully someone experienced with PR's will respond.

Good luck on your project!

Good luck on your project!

I use the SB17CRC-8 and a SB26STCN tweeter in a 7"x12"x9" bookshelf. 4th order filter on the woofer to really push those cone breakup resonances down, and a 3rd order with tweeter.

I am using a stuffed sealed box, using denim insulation.

Really good low end on this speaker in a sealed box. Meaningful 35Hz, not much audible below that tho. And quite tight sounding on drums and percussion.

I am using a stuffed sealed box, using denim insulation.

Really good low end on this speaker in a sealed box. Meaningful 35Hz, not much audible below that tho. And quite tight sounding on drums and percussion.

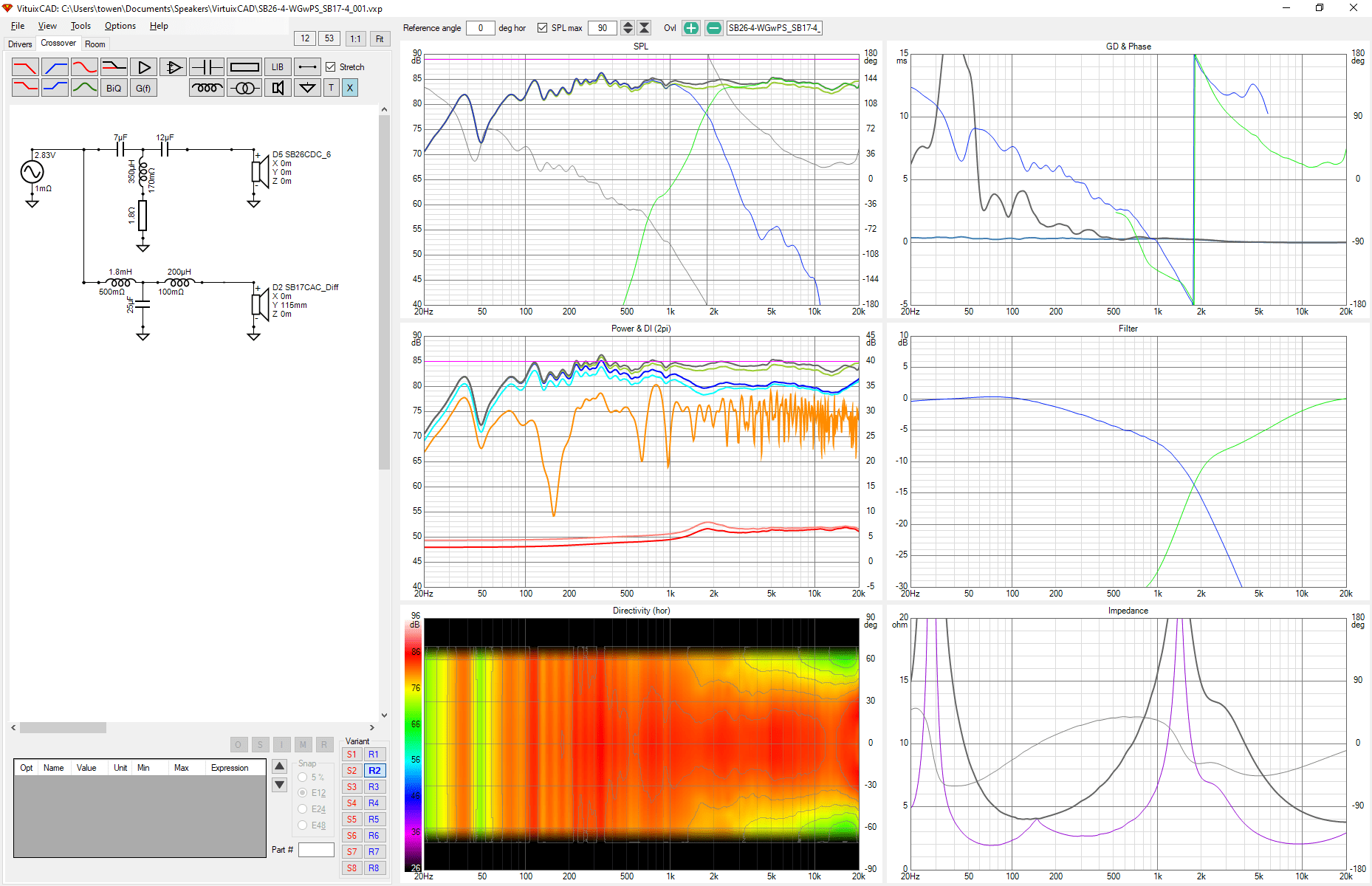

Cooked up a crossover. Tried a few things with different cross frequencies, filter orders, and adding a notch. I think this simple filter will do what I need. Huge dip at 150 is the floor bounce. Directivity doesn't line up as well as with the smaller midrange and waveguide in my other build, but good enough at the 1.8kHz cross over.

Decided to go ported, the location does have some room to breath and it is just easier and cheaper at the end of the day.

Going to order parts and start the build soon. For the cost curious it will be about $500 in drivers and cross over parts, $200-250 to MJF/SLS nylon print the waveguide (may go for glass bead filled this time), have the $60 in MDF on hand, tools on hand (~$1k for table saw, router, etc.), veneer will borrow from my stash of raw wood Bolivian rosewood (would be $150 for a decent sheet).

Decided to go ported, the location does have some room to breath and it is just easier and cheaper at the end of the day.

Going to order parts and start the build soon. For the cost curious it will be about $500 in drivers and cross over parts, $200-250 to MJF/SLS nylon print the waveguide (may go for glass bead filled this time), have the $60 in MDF on hand, tools on hand (~$1k for table saw, router, etc.), veneer will borrow from my stash of raw wood Bolivian rosewood (would be $150 for a decent sheet).

On that crossover design, your impedance really spikes past 20 ohms centered around 1.5khz. will this be used with a tube amp? Tubes generally dont like big changes in impedance.

Also, check out the SB Acoustics open source Bromo project. It uses the same drivers you have chosen, and the recommended crossover is available.

https://sbacoustics.com/product/bromo/

Also, check out the SB Acoustics open source Bromo project. It uses the same drivers you have chosen, and the recommended crossover is available.

https://sbacoustics.com/product/bromo/

I’m by no means an expert, but if I’m not mistaken you can often physically add mass to a passive radiator to lower its resonant frequency. If one PR has a slightly too high Fs and one has a slightly too low fs, adding a bit of mass to the high fs PR will give your desired frequency.

Progress with the project.

Got the cabinet parts ripped on the table saw and got halfway through the driver rebates before running out of daylight. This batch of MDF is darker and denser than what I have worked with in the past. Not quite HDF, but much denser than what I usually use.

Initial crossover parts in hand. Most likely change is a slight adjustment in the tweeter inductor depending on the power response in the crossover region once everything is the in the cabinet.

Waveguides are gorgeous. Got them done in glass bead filled PA12 MJF. Went for the higher performance material for the extra stiffness at this larger size and added more reinforcement to the phase shield over my past effort (broke and glued the shield on my 5" ones). Much better protection for the tweeter, some subtle warping that won't be noticable when assembled as it seems the printer chose their own orientation (not a big deal, could have paide extra to have forced orientation). These have to make a trip across the ocean so wanted to be more assured they would hold up.

Next up is finishing the rebates and the glue up. Then we do bitumen pads and stuffing.

Got the cabinet parts ripped on the table saw and got halfway through the driver rebates before running out of daylight. This batch of MDF is darker and denser than what I have worked with in the past. Not quite HDF, but much denser than what I usually use.

Initial crossover parts in hand. Most likely change is a slight adjustment in the tweeter inductor depending on the power response in the crossover region once everything is the in the cabinet.

Waveguides are gorgeous. Got them done in glass bead filled PA12 MJF. Went for the higher performance material for the extra stiffness at this larger size and added more reinforcement to the phase shield over my past effort (broke and glued the shield on my 5" ones). Much better protection for the tweeter, some subtle warping that won't be noticable when assembled as it seems the printer chose their own orientation (not a big deal, could have paide extra to have forced orientation). These have to make a trip across the ocean so wanted to be more assured they would hold up.

Next up is finishing the rebates and the glue up. Then we do bitumen pads and stuffing.

Nice! Did you use the augerpro waveguides as a reference? And will you perform final measurements?

Yes, these are Augerpro waveguide profiles. Made my own phase shield (same location and size) and the big modification is the round rebate and tucked close woofer cut. Round is just easy on the router with jig. Always like close spaced drivers as well.

The assembly will have bluetack to seal the tweeter at the perimeter (not near the surround). The hexes you see will have nuts glued in and a backing plate screwed on with some foam will hold the rear cup to secure the tweeter.

The assembly will have bluetack to seal the tweeter at the perimeter (not near the surround). The hexes you see will have nuts glued in and a backing plate screwed on with some foam will hold the rear cup to secure the tweeter.

Have let this thread lay behind my build, the speakers are done. Just need to do the veneer.

No such thing as too many clamps. Seriously, just get more. Better bonds and more square boxes.

After the first cabinet glue up getting the damping material glued in, I use DAP flooring glue.

The batting, 1" of cotton/denim insulation and .5" of polyfil (they are optimistic on that spec).

Getting the 1.5" round overs on. Takes a vicious router but to do the job. Started with a 45deg pass on the router to save the bit for the finish cut.

The crossovers done up.

3d printed harmen porta styled to match the drivers.

Test fitting it all together.

Prepping the rosewood raw wood for veneer.

No such thing as too many clamps. Seriously, just get more. Better bonds and more square boxes.

After the first cabinet glue up getting the damping material glued in, I use DAP flooring glue.

The batting, 1" of cotton/denim insulation and .5" of polyfil (they are optimistic on that spec).

Getting the 1.5" round overs on. Takes a vicious router but to do the job. Started with a 45deg pass on the router to save the bit for the finish cut.

The crossovers done up.

3d printed harmen porta styled to match the drivers.

Test fitting it all together.

Prepping the rosewood raw wood for veneer.

For the first of the set veneered and one coat of 2lb cut shellac on them to start the French polish. Raw wood veneer is a massive pain to work over curves, dreading working on the big boys now. Got an area on the front I had to repair where the veneer disintegrated, color match ended up not great so may cut it out and try again

Despite my shortcomings they look amazing. Even if I don't fix everything they are a cabinet I think I can be proud of.

I will suggest strongly if you have tight curves (1.5in/40mm radius in this case) just stay away from raw wood veneer unless you have experience or are willing to make repairs. For me this wood is quite $$$ so willing to give it the effort to make it work

Despite my shortcomings they look amazing. Even if I don't fix everything they are a cabinet I think I can be proud of.

I will suggest strongly if you have tight curves (1.5in/40mm radius in this case) just stay away from raw wood veneer unless you have experience or are willing to make repairs. For me this wood is quite $$$ so willing to give it the effort to make it work

They are now in their home just outside Shanghai.

The natural shellac survived the luggage fairly well, brought a bit with me and some walnut oil to give the final polish. They have a massive room to fill and do a surprisingly decent job for the size. My in-laws arent base heads, so good enough.

The big room makes me wish I had more space, as reflective as the room is you really don't hear the sidewalls at the sweet spot.

I think I can recommend the Wiim Amp Pro to anyone setting up a system for a non-audio/tech person. I did the EQ for them. Was able to create presets for TV and Bluetooth as well as the phone app being convenient and translated in a ton of languages. Hardest part was the first Bluetooth pairing.

The natural shellac survived the luggage fairly well, brought a bit with me and some walnut oil to give the final polish. They have a massive room to fill and do a surprisingly decent job for the size. My in-laws arent base heads, so good enough.

The big room makes me wish I had more space, as reflective as the room is you really don't hear the sidewalls at the sweet spot.

I think I can recommend the Wiim Amp Pro to anyone setting up a system for a non-audio/tech person. I did the EQ for them. Was able to create presets for TV and Bluetooth as well as the phone app being convenient and translated in a ton of languages. Hardest part was the first Bluetooth pairing.

Sin Phi,

Congratulations - a very well executed project, and the speakers look gorgeous. Your in-laws have a beautiful place, and the new speakers are a fitting addition.

Clever idea of making the flange of the wave guide circular. 🙂 I also had my wave guides printed in MJF, and yes the material feels very sturdy.

Did you print the ports by yourself?

Congratulations - a very well executed project, and the speakers look gorgeous. Your in-laws have a beautiful place, and the new speakers are a fitting addition.

Clever idea of making the flange of the wave guide circular. 🙂 I also had my wave guides printed in MJF, and yes the material feels very sturdy.

Did you print the ports by yourself?

Yes, they are based on a scaling of the Harmen port from their journal article. They are just a simple PLA print. Not going to see much heat and the tube geometry is resistive to creep. For parts that touch the drivers I stick with ABS or nylon.Did you print the ports by yourself?

- Home

- Loudspeakers

- Multi-Way

- SB Acoustics 2-way as gift, bass alignment?