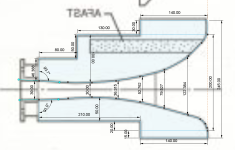

I'm planning out a build of a TAD 2404 "inspired" build with a clone of the TH4003 horn. I sketched out the horn top, bottom and side profiles in Fusion 360 from a copy of a TH4003 spec in this post here: https://www.diyaudio.com/community/threads/new-project-tad-2404-clone.322939/post-5440074

Let me know if anything looks wrong in my dimensions or if there are better sources of plans available.

When I get the 3d model put together I plan to model in ABEC3/Akabak which I have not had much luck with in the past.

I will be using a benchtop CNC router which should be just big enough for this project by a cm or two in every direction. Either Douglas Fir or western (big leaf) maple for the first version. The horn will be made in four parts: top, bottom, and 2 sides. I also plan to make the throat adapter on my CNC from sandwiched plywood.

Given a single used D-4003 compression driver costs more than my entire budget for this project I am planning to make a throat adapter to allow me to use a 1.4" compression driver. The Radian 745 NEo is currently at the top of my list but open to suggestions.

For the woofer the B&C 15PS100 and Cair 15NDH-4S model pretty close to the TAD TL-1601 in my WinISD models, but I may just spring for a used pair of TL-1601s.

I will be running this active with a MiniDSP and a 4 channel Bryston 7B, with crossover around 650hz. So no passive crossover at least to start with.

Let me know if anything looks wrong in my dimensions or if there are better sources of plans available.

When I get the 3d model put together I plan to model in ABEC3/Akabak which I have not had much luck with in the past.

I will be using a benchtop CNC router which should be just big enough for this project by a cm or two in every direction. Either Douglas Fir or western (big leaf) maple for the first version. The horn will be made in four parts: top, bottom, and 2 sides. I also plan to make the throat adapter on my CNC from sandwiched plywood.

Given a single used D-4003 compression driver costs more than my entire budget for this project I am planning to make a throat adapter to allow me to use a 1.4" compression driver. The Radian 745 NEo is currently at the top of my list but open to suggestions.

For the woofer the B&C 15PS100 and Cair 15NDH-4S model pretty close to the TAD TL-1601 in my WinISD models, but I may just spring for a used pair of TL-1601s.

I will be running this active with a MiniDSP and a 4 channel Bryston 7B, with crossover around 650hz. So no passive crossover at least to start with.

Attachments

tad 2402 or 2404 is the ultimate diy speaker which has cloned investiaged a lot first by MJ magazine editor yuchi then the other forum. His investigate lead to a lot of reference desgin for diy community such as the yuchi horn (which there should be CAD file in the internet way back machine) and the rferenced woofer cabinet desgin aria-170 which also include all the proper bracing and port . He had experience ran the thing in dsp. I do not recommend cheap out the componets of this build as this item wil be a keeper, becasue currently there are no woofer is on par with tad tl 1601/2/3, JBL/GPA woofer and the only compression driver that could rival the tad was only developed a few years ago , (celstion axi series)

A few years ago this forum has made 3D model simulation of for the horn which should include the proper cad for CNC, i mean proper becasue your attachement diagram does not inlcude fins inside the horn which helps the accoustic diffraction, if you like Joesph crows work you can visit his website and order a CNC.

Also the french forum https://www.forum-bleu.com/ and https://www.homecinema-fr.com/forum/ have many discssion onthe 2402 model the woofer and horn. In french the 2402 model is call tsm 2. I remember the french magazine audiotechque (spelling) also have an issue dedicated on reviewing the 2402. please also note the 2402 is slightly larger than tsm 2.

https://www.homecinema-fr.com/forum...ad-1601-pour-une-enceinte-tsm1-t30046397.html

A few years ago this forum has made 3D model simulation of for the horn which should include the proper cad for CNC, i mean proper becasue your attachement diagram does not inlcude fins inside the horn which helps the accoustic diffraction, if you like Joesph crows work you can visit his website and order a CNC.

Also the french forum https://www.forum-bleu.com/ and https://www.homecinema-fr.com/forum/ have many discssion onthe 2402 model the woofer and horn. In french the 2402 model is call tsm 2. I remember the french magazine audiotechque (spelling) also have an issue dedicated on reviewing the 2402. please also note the 2402 is slightly larger than tsm 2.

https://www.homecinema-fr.com/forum...ad-1601-pour-une-enceinte-tsm1-t30046397.html

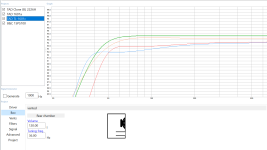

For the woofer it seems hard to find a match for the TL-1601c. The JBL 2226H wants a smaller box and even with a much higher tuning frequency still shows lower sensitivity compared with the TL-1601c.

In the winISD chart I am using a 120L enclosure. Green=1601c, Orange=1601a, Red=JBL 2226h, Blue=B&C 15PS100

In the winISD chart I am using a 120L enclosure. Green=1601c, Orange=1601a, Red=JBL 2226h, Blue=B&C 15PS100

Attachments

I'm planning to do a TH-4003 replica which I believe is the first TAD made without fins. I'm a big fan of Joseph Crowe (Troy's) work but prefer the harder edge look of the original TADs. His designs are two piece and look to require a bigger CNC to get the depth of cut. Going from initial CAD design -> finished CNC is one of the challenges I wanted to take on myself for this project.

I did find some Akabak results for the TH4003 here which were generated from a step file: https://sphericalhorns.net/2024/07/05/a-true-grand-cinema-horn/

I did find some Akabak results for the TH4003 here which were generated from a step file: https://sphericalhorns.net/2024/07/05/a-true-grand-cinema-horn/

Attachments

if you are looking for

for cabinet building the original cabinet and horn uses cherrywood, so you need to source something similar hardness. I doubt th003 is for prosumer more of a cinema uses. But this could only know if someone simulate it.

In terms of building the horn without using a big CNC you can make layers (see link). Below is a japanese blog about his journey in making the horn and expereince hopefully give you some direction on the build

https://milestad.hatenablog.com/entry/2023/05/20/212740

PS I'm still searching the horn simulation in this forum which has particles flyout showing the result the result on the optimaization. If someone found it please kindly pm me the link.

for the woofer you wont find new 1601c the factory making it is gone, i only saw 1 1601c avaliable for auction in the past 3 years in yahoo auction jp. The best you can do is to wait for 1601a 1602b and 1603 in yahoo auction jp or order a new1601b. For woofer cabinet desgin I dont think further time is needed to reinvent the wheel, else rey audio would alo JBL/GPA woofer instead of tl1601/1602.iFor the woofer it seems hard to find a match for the TL-1601c. The JBL 2226H wants a smaller box and even with a much higher tuning frequency still shows lower sensitivity compared with the TL-1601c.

In the winISD chart I am using a 120L enclosure. Green=1601c, Orange=1601a, Red=JBL 2226h, Blue=B&C 15PS100

for cabinet building the original cabinet and horn uses cherrywood, so you need to source something similar hardness. I doubt th003 is for prosumer more of a cinema uses. But this could only know if someone simulate it.

In terms of building the horn without using a big CNC you can make layers (see link). Below is a japanese blog about his journey in making the horn and expereince hopefully give you some direction on the build

https://milestad.hatenablog.com/entry/2023/05/20/212740

PS I'm still searching the horn simulation in this forum which has particles flyout showing the result the result on the optimaization. If someone found it please kindly pm me the link.

That would be my advice too. He is a good guy ( not the cheapest ) and I was his first customer years ago.

Well, the idea is to DIY not buy. Well aware I am not saving money when I factor in my time and I already have the tools. I think I am getting pretty close with the design.

Last edited by a moderator:

Your design deviates a little still.Well, the idea is to DIY not buy. Well aware I am not saving money when I factor in my time and I already have the tools. I think I am getting pretty close with the design.

Your back end especially on the top is quite different.

Not sure if that is on prupose? Adds some rigidity i guess, although shouldn't be needed. also complicates the shape and mfg.

You omitted the AFAST - Helmoltz absorber. Which is what the little square block exttension on the top back is.

You see the "foamed" entrance on the front.

https://www.pioneerdj.com/en/product/features/monitor-speakers/afast-technology/

https://audio-database.com/PIONEER-EXCLUSIVE/speaker/model2404.html

I suggest you take a look at audioheritage.org forums on the subject also.

Attachments

Last edited:

Yeah the top profile was because I directly traced the side profile from TH4003_spec.jpg (which includes bump out for the AFAST port) then performed a 80 degree sweep in Fusion 360 to get the 3d model. The final build will look more like the top profile of the TH4003, that side of the horn won't get touched by the CNC so I did not bother to go back and correct it. As you said, it's just wasted stock and doesn't need to be there.

I was planning to omit the AFAST port to begin with, as most of the other builders of TAD style horns (GT Sound, Classic Audio, Joseph Crowe, etc) leave it out. I see Athos has the AFAST port. I think I would need a drill press to do it right, and it is something I would want to do before CNC so that if I screw up it can possibly be fixed and not ruin a horn after days of CNC time. Also I would want to measure a working horn to know what it is doing. I have put together some simple models with ATH/ABEC3/Akabak using a horn which is similar in dimension and see there is a few db of horn honk around 2khz. I thing having the rear chamber of the afast port be detachable could allow it to be tunable based on where the honk is. For the first rev I will just add a notch filter in my minidsp but absorbing the horn resonance would probably sound better than just EQing it down.

I was planning to omit the AFAST port to begin with, as most of the other builders of TAD style horns (GT Sound, Classic Audio, Joseph Crowe, etc) leave it out. I see Athos has the AFAST port. I think I would need a drill press to do it right, and it is something I would want to do before CNC so that if I screw up it can possibly be fixed and not ruin a horn after days of CNC time. Also I would want to measure a working horn to know what it is doing. I have put together some simple models with ATH/ABEC3/Akabak using a horn which is similar in dimension and see there is a few db of horn honk around 2khz. I thing having the rear chamber of the afast port be detachable could allow it to be tunable based on where the honk is. For the first rev I will just add a notch filter in my minidsp but absorbing the horn resonance would probably sound better than just EQing it down.

The TH-4003 APAXIAL (Asymetrical Pattern, Axis & Level) horn polar response appears to have a slightly elevated wide band symmetrical "lift" centered in the 2kHz range.Also I would want to measure a working horn to know what it is doing. I have put together some simple models with ATH/ABEC3/Akabak using a horn which is similar in dimension and see there is a few db of horn honk around 2khz. I thing having the rear chamber of the afast port be detachable could allow it to be tunable based on where the honk is.

The AFAST (Acoustical Filter Assisted System Tuning) Helmholtz port could only absorb a single narrow frequency range focused in a particular horn area.

https://www.audioheritage.org/vbulletin/showthread.php?43606-New-Mid-horn-experiment

Looking at eso's measurements without the AFAST port on his TAD TD4001/TH-4003 based horn:

Near 4kHz, response shows ~9dB (1/2 or twice as "loud") on axis deviation between 15 degrees up and 15 degrees down, no other frequencies show such a drastic change.

4kHz also happens to be where most normal hearing response is most sensitive.

My guess is that frequency range would be the target for the AFAST on his horn.

Good idea, and internal horn measurements will be required to find the optimum AFAST location for your particular horn profile.Also I would want to measure a working horn to know what it is doing.

Art

Note that the GT Sound, Classic Audio, Joseph Crowe horns are all vertically symmetrical, as is the TAD TH-4001, while the TH-4003 is not.I was planning to omit the AFAST port to begin with, as most of the other builders of TAD style horns (GT Sound, Classic Audio, Joseph Crowe, etc) leave it out. I see Athos has the AFAST port.

The Athos TAD TH-4001 has no port, their version of the TH-4003 APAXIAL does use the AFAST.

Weltersys gave you a very good explanation already.Are there any frequency response comparison charts showing what the AFAST port is doing?

It is a basic Helholtz "absorber" / resonator.

With accurate drawing of the chamber" along with hole diameter etc you can extrapolate the Frequency with a Helmholtz calculator fairly accurately also.

Hi Art, Arez,

Kindest regards,

M

As I will eventually be in possession of that horn, could you please advise how to design the AFAST?Near 4kHz, response shows ~9dB (1/2 or twice as "loud") on axis deviation between 15 degrees up and 15 degrees down, no other frequencies show such a drastic change.

4kHz also happens to be where most normal hearing response is most sensitive.

My guess is that frequency range would be the target for the AFAST on his horn.

Kindest regards,

M

I know what it does. I'm asking if there's a response chart with two measurements on it, one with the port, one with it covered up.Weltersys gave you a very good explanation already.

It is a basic Helholtz "absorber" / resonator.

With accurate drawing of the chamber" along with hole diameter etc you can extrapolate the Frequency with a Helmholtz calculator fairly accurately also.

M,As I will eventually be in possession of that horn, could you please advise how to design the AFAST?

I don't have the specifics of the material density used for absorption or the specific frequency range targeted in TAD's various AFASTs, or what horn you will eventually be in possession of, but their design works like all Helmholtz absorbers: when sound waves of the resonant frequency reach the resonator, the air in the neck oscillates, and the air in the cavity compresses and expands, creating friction and converting the sound energy into heat, absorbing the sound.

The relationship between the "neck", "cavity", and the material in the cavity all work together, changes in any of the three affect it's resonant frequency.

Art

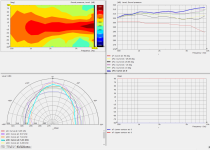

After dozens of unsuccessful attempts at attempting to simulate my TH-4003 in Akabak I was finally able to get some results which are starting to look like what I would reasonably expect from the horn. My first attempts resulted in Akabak spitting out a chart of random resonances due to the model mesh density being too low. Higher resolution mesh models resulted in Akabak hanging for hours or even days, sometimes running out of memory. And this is on a AMD Threadripper 1920X with 128GB of RAM FWIW.

I finally had success by meshing the model directly in Fusion 360 with a maximum edge length of 1CM, surface deviation of 0.1mm, and normal deviation of 15 degrees. Then I remeshed the outer areas of the horn to around 4cm to keep Akabak from grinding to a halt. Imported the STL mesh form Fusion 360 directly into Akabak, ran the simulation and by morning had some results.

Even with this model it starts to breakup about 10khz so I am only able to model that high.

One thing interesting compared to other ATH4 generated horns I have played around with is this one appears to load more the higher up you go in the frequency range.

On the vertical axis the balloon plot is good at showing the Asymmetric dispersion of the horn below vertical. It's subtle but there's a clear shift.

I'm going to post the fusion 360 files, STL files, and Akabak projects up on Github later today, in case any Akabak wizards can work their magic on it.

I finally had success by meshing the model directly in Fusion 360 with a maximum edge length of 1CM, surface deviation of 0.1mm, and normal deviation of 15 degrees. Then I remeshed the outer areas of the horn to around 4cm to keep Akabak from grinding to a halt. Imported the STL mesh form Fusion 360 directly into Akabak, ran the simulation and by morning had some results.

Even with this model it starts to breakup about 10khz so I am only able to model that high.

One thing interesting compared to other ATH4 generated horns I have played around with is this one appears to load more the higher up you go in the frequency range.

On the vertical axis the balloon plot is good at showing the Asymmetric dispersion of the horn below vertical. It's subtle but there's a clear shift.

I'm going to post the fusion 360 files, STL files, and Akabak projects up on Github later today, in case any Akabak wizards can work their magic on it.

Attachments

- Home

- Loudspeakers

- Multi-Way

- DIYing TAD TH-4003s...