When designing small enclosures, I often tune them to emphasize the 100Hz to 300Hz range, but in this case I aimed for gentle low frequencies, assuming the enclosure would be used close to a wall.

The measurements and recordings were taken 1.2 meters away from the wall, but the low frequency range improves when placed close to the wall.

The measurements and recordings were taken 1.2 meters away from the wall, but the low frequency range improves when placed close to the wall.

Attachments

I measured the frequency response with the box close to the wall.

The frequency response of the duct remains the same, but the frequency response at 1m on axis seems to be much improved in the low frequency range.

The frequency response of the duct remains the same, but the frequency response at 1m on axis seems to be much improved in the low frequency range.

Nicely shaped box for wall placement. You could just hang a pair on the walls, Add 45° bevels on the sides to minimize the transition from the baffle to the wall.

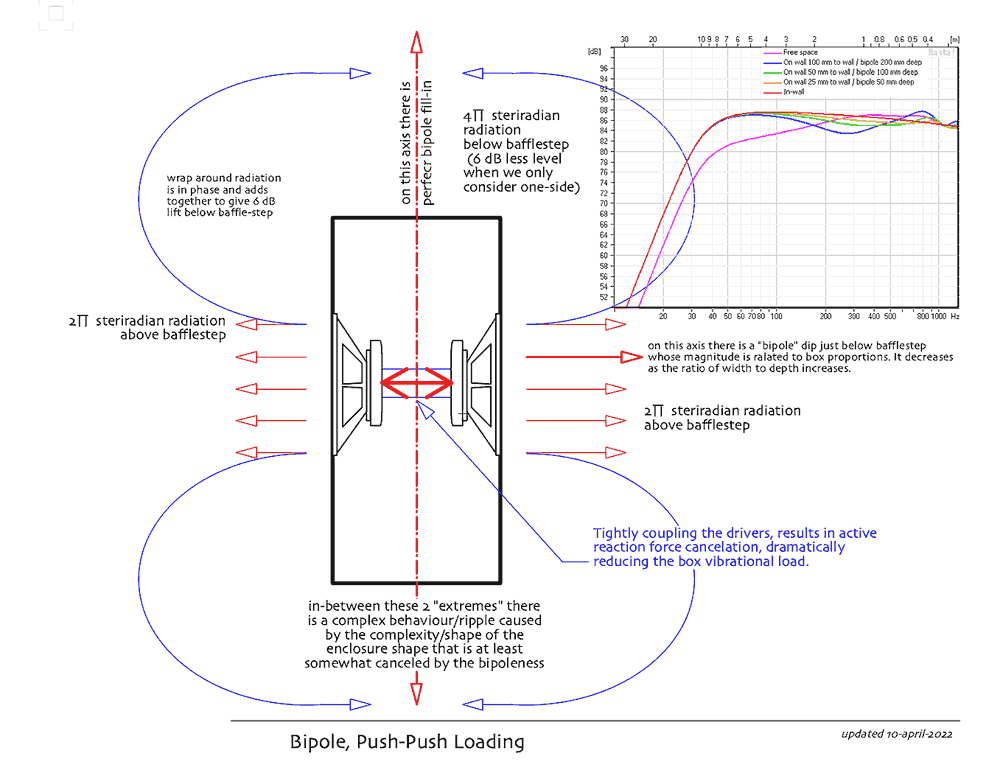

But it is shallow enuff and wide enuff it may not make much difference. The diagram is to illustrate a push-push bipole, but the graph is a recreation of a Swedish members sim of (rectangular) box-on-all behaviour. As width to depth ratio increases the dip decreases.

Is the back wall close enuff that you can hear it coming back thru the cone, We had that issue with some of our skinny speakers.

dave

But it is shallow enuff and wide enuff it may not make much difference. The diagram is to illustrate a push-push bipole, but the graph is a recreation of a Swedish members sim of (rectangular) box-on-all behaviour. As width to depth ratio increases the dip decreases.

Is the back wall close enuff that you can hear it coming back thru the cone, We had that issue with some of our skinny speakers.

dave

Last edited:

Thanks, dave.

The board is so thin that large chamfers cannot be made.

The chamfer may not be necessary as it is very flat and nice to listen to.

There doesn't seem to be any influence from the back wall.

The board is so thin that large chamfers cannot be made.

The chamfer may not be necessary as it is very flat and nice to listen to.

There doesn't seem to be any influence from the back wall.

nandappe,

You can add strips made of wood or foam type of materials to the sides to get a chamfered/beveled effect on baffle. Something like the attached image, which is of a beveled strip, a chamfered strip will be easier to make.

You can add strips made of wood or foam type of materials to the sides to get a chamfered/beveled effect on baffle. Something like the attached image, which is of a beveled strip, a chamfered strip will be easier to make.

Last edited by a moderator:

Thank you.

In summary, it looks something like this?

D > E > C > B > A

I had listened to and compared A and D before, but I couldn't tell the difference.

The difference might not be apparent if the enclosure depth is short.

In summary, it looks something like this?

D > E > C > B > A

I had listened to and compared A and D before, but I couldn't tell the difference.

The difference might not be apparent if the enclosure depth is short.

D > E > C > B > A

I had listened to and compared A and D before, but I couldn't tell the difference.

Yes. Given the large width to depth ratio it will be subtle at best.

dave

Last edited:

Hello everyone!

First of all, I want to thank nandappe for sharing his acoustics drawings.

I decided to repeat this project, but encountered poor sound quality. I am almost sure that this is a mistake on my part and I have no doubt that nandappe makes good projects.

The only differences in my acoustics:

1) I used a material thickness of 10 mm instead of 9 mm. Without changing the overall dimensions of the case. Therefore, the volume is slightly smaller.

2) There are also small holes for screwing in bolts on the back wall to hang the acoustics on the wall. For the sound test, I sealed these holes tightly.

3) On the back side, where the speaker is mounted, I made uneven indentations in the MDF, cut out part of the MDF. Since due to the 10 mm thickness of the MDF, the ventilation in the speaker basket was quite blocked, it seemed to me that with these cuts the speaker would get more freedom from the side of the basket. (This is shown in one of the attached photos).

4) I used a little more sound-absorbing material in the speaker compartment (very slightly).

When listening after complete assembly, I immediately heard shortcomings in the midrange. This is especially noticeable on female vocals.

I listen to these speakers from the PAM8406 amplifier, which I have not used with other speakers before.

At first I thought that maybe the amplifier was the problem. I changed different power supplies for it and even converted it from class D to AB, but nothing changed in these sound distortions. Unfortunately, I don’t have another amplifier right now to try with it. I also changed sound sources.

Please tell me where I went wrong?

I really wouldn’t want to break the boxes, they are securely glued,

all the joints are well glued and all the partitions do not have unnecessary gaps, etc.

I understand that it is possible to add sound-absorbing material, but it seems to me that nandappe has a little less of it and it sounds great in video examples.

I am afraid to unscrew and screw the drivers back in several times, because the holes may then hold the screws worse.

At the end, I attach a video, please listen to it, it is especially well heard at the end of the video.

Thank you all in advance for your advice!

Video with problem.

First of all, I want to thank nandappe for sharing his acoustics drawings.

I decided to repeat this project, but encountered poor sound quality. I am almost sure that this is a mistake on my part and I have no doubt that nandappe makes good projects.

The only differences in my acoustics:

1) I used a material thickness of 10 mm instead of 9 mm. Without changing the overall dimensions of the case. Therefore, the volume is slightly smaller.

2) There are also small holes for screwing in bolts on the back wall to hang the acoustics on the wall. For the sound test, I sealed these holes tightly.

3) On the back side, where the speaker is mounted, I made uneven indentations in the MDF, cut out part of the MDF. Since due to the 10 mm thickness of the MDF, the ventilation in the speaker basket was quite blocked, it seemed to me that with these cuts the speaker would get more freedom from the side of the basket. (This is shown in one of the attached photos).

4) I used a little more sound-absorbing material in the speaker compartment (very slightly).

When listening after complete assembly, I immediately heard shortcomings in the midrange. This is especially noticeable on female vocals.

I listen to these speakers from the PAM8406 amplifier, which I have not used with other speakers before.

At first I thought that maybe the amplifier was the problem. I changed different power supplies for it and even converted it from class D to AB, but nothing changed in these sound distortions. Unfortunately, I don’t have another amplifier right now to try with it. I also changed sound sources.

Please tell me where I went wrong?

I really wouldn’t want to break the boxes, they are securely glued,

all the joints are well glued and all the partitions do not have unnecessary gaps, etc.

I understand that it is possible to add sound-absorbing material, but it seems to me that nandappe has a little less of it and it sounds great in video examples.

I am afraid to unscrew and screw the drivers back in several times, because the holes may then hold the screws worse.

At the end, I attach a video, please listen to it, it is especially well heard at the end of the video.

Thank you all in advance for your advice!

Video with problem.

Attachments

Hello everyone!

First of all, I want to thank nandappe for sharing his acoustics drawings.

I decided to repeat this project, but encountered poor sound quality. I am almost sure that this is a mistake on my part and I have no doubt that nandappe makes good projects.

The only differences in my acoustics:

1) I used a material thickness of 10 mm instead of 9 mm. Without changing the overall dimensions of the case. Therefore, the volume is slightly smaller.

2) There are also small holes for screwing in bolts on the back wall to hang the acoustics on the wall. For the sound test, I sealed these holes tightly.

3) On the back side, where the speaker is mounted, I made uneven indentations in the MDF, cut out part of the MDF. Since due to the 10 mm thickness of the MDF, the ventilation in the speaker basket was quite blocked, it seemed to me that with these cuts the speaker would get more freedom from the side of the basket. (This is shown in one of the attached photos).

4) I used a little more sound-absorbing material in the speaker compartment (very slightly).

When listening after complete assembly, I immediately heard shortcomings in the midrange. This is especially noticeable on female vocals.

I listen to these speakers from the PAM8406 amplifier, which I have not used with other speakers before.

At first I thought that maybe the amplifier was the problem. I changed different power supplies for it and even converted it from class D to AB, but nothing changed in these sound distortions. Unfortunately, I don’t have another amplifier right now to try with it. I also changed sound sources.

Please tell me where I went wrong?

I really wouldn’t want to break the boxes, they are securely glued,

all the joints are well glued and all the partitions do not have unnecessary gaps, etc.

I understand that it is possible to add sound-absorbing material, but it seems to me that nandappe has a little less of it and it sounds great in video examples.

I am afraid to unscrew and screw the drivers back in several times, because the holes may then hold the screws worse.

At the end, I attach a video, please listen to it, it is especially well heard at the end of the video.

Thank you all in advance for your advice!

Video with problem.

Hi dizzydevil,

It sounds a bit chirpy (distorted).

1. Poor wiring contact (sometimes the chattering appears in forte)

2. Poor installation (air leakage, raised screw holes)

3. Defective driver

4. Excessive cutting of the backside of the opening (gap between the partition plates? and insufficient strength?)

5. Insufficient wall strength?

Attachments

......or Vc rubbing in the gap.Sounds like amplifier clipping to me.

Thank you for your reply!

I am almost certain that I have no gaps or air leaks.

The cut surface on the back side is in places that do not touch the partitions. All connections are very tight.

I ordered another sound amplifier. As soon as I receive it and test the speakers with the new amplifier, I will write here about the result, if the problem turns out to be in the amplifier.

For now, I really would not like to break the speaker housings.

I am almost certain that I have no gaps or air leaks.

The cut surface on the back side is in places that do not touch the partitions. All connections are very tight.

I ordered another sound amplifier. As soon as I receive it and test the speakers with the new amplifier, I will write here about the result, if the problem turns out to be in the amplifier.

For now, I really would not like to break the speaker housings.

- Home

- Loudspeakers

- Full Range

- MarkAudio CHN-50P and thin enclosure(W.300mm x H.300mm x D:58mm)