Hello!!

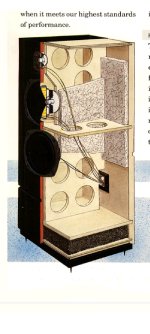

I rebuilt my (acoustic suspension) loudspeaker with 20mm thick bamboo plywood.

As you can see the attached picture, it has some bracings inside the speaker, what type of bracing would you recommend? Marine grade mahogany plywood, spruce, baltic birch or stick with same type of bamboo plywood for the cabinet?

I also attached some pictures about marine grade mahogany plywood I can get from the local shop.

Thanks 🙏

I rebuilt my (acoustic suspension) loudspeaker with 20mm thick bamboo plywood.

As you can see the attached picture, it has some bracings inside the speaker, what type of bracing would you recommend? Marine grade mahogany plywood, spruce, baltic birch or stick with same type of bamboo plywood for the cabinet?

I also attached some pictures about marine grade mahogany plywood I can get from the local shop.

Thanks 🙏

Attachments

Last edited:

BTW, my cabinet maker is working on the cabinet with the bamboo plywood as the attached pix shown.

Attachments

No real view of the contruction of the ply, but it looks to be block core — what grade of surface veneers?

You can use any decent plywood if you are trying to save money, if you don’t have a use for the left over bamboo you can ue it. I believ we have done both with our Bamboo cabinets, The firt one we builkt back and other bits are ply, there was only a half sheet of bamboo left over from someone else’s project.

I would rotate the horizontal brace you have in your visualization.

dave

You can use any decent plywood if you are trying to save money, if you don’t have a use for the left over bamboo you can ue it. I believ we have done both with our Bamboo cabinets, The firt one we builkt back and other bits are ply, there was only a half sheet of bamboo left over from someone else’s project.

I would rotate the horizontal brace you have in your visualization.

dave

Last edited:

Bamboo is very stiff, so you've got the two options of either getting the extreme braces to increase the frequency of the board frequency by brute force/stiffness or you are using the soft method of absorbing it by including dampened braces (glued on one side, Alubutyl etc on the other side.

I do not recomment bamboo as speaker material in general since it's a quick growing grass (yes, it is!) and contains so much silica (silica oxyde) it extremely quickly dulls your tools, reducing their lifetime easily to 1/5th. Not by but to. Aside from that, it got some extremely good properties but an equally magnitude of negative attributes. No free lunch in physics.

I do not recomment bamboo as speaker material in general since it's a quick growing grass (yes, it is!) and contains so much silica (silica oxyde) it extremely quickly dulls your tools, reducing their lifetime easily to 1/5th. Not by but to. Aside from that, it got some extremely good properties but an equally magnitude of negative attributes. No free lunch in physics.

Bamboo ply (stranded/fossilized) is the best flat speakerf building material we have used. Some of the Richjlite could be even better.

dave

dave

Other than tooling issues, I don't see any drawbacks on my side as it is made by the carpenters. I am the end user 😂Bamboo is very stiff, so you've got the two options of either getting the extreme braces to increase the frequency of the board frequency by brute force/stiffness or you are using the soft method of absorbing it by including dampened braces (glued on one side, Alubutyl etc on the other side.

I do not recomment bamboo as speaker material in general since it's a quick growing grass (yes, it is!) and contains so much silica (silica oxyde) it extremely quickly dulls your tools, reducing their lifetime easily to 1/5th. Not by but to. Aside from that, it got some extremely good properties but an equally magnitude of negative attributes. No free lunch in physics.

I try to get the spruce and checking the availability for the size I need for the brace.

I have seen my friend using Delrin as the top section baffle for his Linkwitz LX521. it is incredible 😍Bamboo ply (stranded/fossilized) is the best flat speakerf building material we have used. Some of the Richjlite could be even better.

dave

I guess the bottom also using some kind of composite material, but not sure. I remember it is plastic as well but very very stiff, made by 3D printing.

Bamboo ply (stranded/fossilized) is the best flat speakerf building material we have used. Some of the Richjlite could be even better.

It got very good properties but it's devastating to your tools. It's like cutting/routing sand stone.

Other than tooling issues, I don't see any drawbacks on my side as it is made by the carpenters. I am the end user 😂

That's exactly the issue. Your routers got about 20-200x the normal tear because silica is a very hard. Just remember, it's used in sanding stones and grinding stones for very hard materials. It does the same to the tools. Just because you don't see it doesn't mean it's affecting you. Think about O² or CO² 😉

Frankly, I have considered to use either lexan or delrin for the bracing. Those are very reasonable pricing here and very easy to access. As they are plastic and able to absorb the vibration.

Normally how thick the material should be used for bracing. The cabinet is 20mm thick.

The thickness should be enough to not vibrate on itself and support enough force transfere between the sides it's connected to. That usually means it can be thinner than the walls but usually isn't reduced in thickness because of optimal use of the material but for PA use, where the weight is a major issue, the braces might be thinnner, though they usually are not.

but it's devastating to your tools

Chris was not quite as harsh… not a hard on tool as medite (HDF with small metal particles in it). Not as hard as metal.

It saves veneering the plywood, like solid.

dave

Normally how thick the material should be used for bracing. The cabinet is 20mm thick.

How big is the box? I would be happy to uw 15mm BB inside 20mm bamboo walls — the best studd is probably stiffer than 35-40mm MDF.

dave

Bamboo

In that direction it's just about 5-15% stiffer than particle board of equal thickness. The boards don't differ very much in that direction. If the braces have to bridge far distances, they are even more suseptible to cross resonances. If that's a problem (very unlikely), I'd no replace it with particle board (better in this situation than MDF) but dampen the ply brace with alubutyl or bitumen instead.

I would be happy to uw 15mm BB inside 20mm bamboo walls — the best studd is probably stiffer than 35-40mm MDF.

In that direction it's just about 5-15% stiffer than particle board of equal thickness. The boards don't differ very much in that direction. If the braces have to bridge far distances, they are even more suseptible to cross resonances. If that's a problem (very unlikely), I'd no replace it with particle board (better in this situation than MDF) but dampen the ply brace with alubutyl or bitumen instead.

What do you think using bamboo plywood as the cabinet and has Delrin as bracings? I have asked the vendor Delrin is able to use with any type of glue. I think Delrin is very stiff and flexible to a degree. Since it is a plastic and should have good damping effect. Any thoughts 🤔How big is the box? I would be happy to uw 15mm BB inside 20mm bamboo walls — the best studd is probably stiffer than 35-40mm MDF.

dave

I can access CNC Delrin at very good price.

Delrin isn’t a material i would use for building loudspeakers.. Makes good TT platters.

dave

dave

I have seen people using both Delrin and polycarbonate as the baffle for Dipole loudspeaker with great results.

For an OB you don't neccessarily have to glue it. For an enclosure it would be a nightmare.

- Home

- Loudspeakers

- Multi-Way

- Question about bracing of bamboo cabinet