Hello everyone,

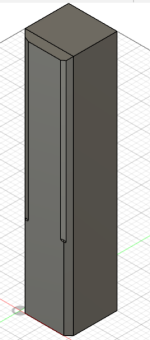

I am building a 3 way enclosure and I have a design idea I would like to implement. However..... I haven't figured out how to do it

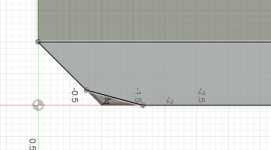

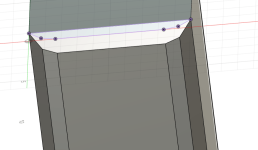

Have a look at my pictures. Basically I want an outer 45 degree chamfer and then an inner 15 degree chamfer on a 3/4" birch plywood enclosure.

The 45 is easy enough with a 45 degree chamfer router bit.

I am unsure of how to get the second 15 degree cut.

Any ideas?

I have a router (hand held) and a table saw (not a good one and I don't really trust it for precision angle cuts)

I am building a 3 way enclosure and I have a design idea I would like to implement. However..... I haven't figured out how to do it

Have a look at my pictures. Basically I want an outer 45 degree chamfer and then an inner 15 degree chamfer on a 3/4" birch plywood enclosure.

The 45 is easy enough with a 45 degree chamfer router bit.

I am unsure of how to get the second 15 degree cut.

Any ideas?

I have a router (hand held) and a table saw (not a good one and I don't really trust it for precision angle cuts)

Attachments

I do have a hand plane though I've only used it a handful of times......good idea. I'm probably not skilled enoiguh with it to get a crisp line with it though

The guide on the router may have a 15 degree setting.

Or use a shim, see 'sine table', a machinist's tool, where guage blocks or shims are used to get the correct angle for machinig.

Difficult with a hand held router.

Or you could obtain a bit / tool with the right profile...

Or use a shim, see 'sine table', a machinist's tool, where guage blocks or shims are used to get the correct angle for machinig.

Difficult with a hand held router.

Or you could obtain a bit / tool with the right profile...

Cut the 15 degree first on a table saw with a guide.

Then cut the 45 deg. on the same table saw.

Use a fine tooth blade, maybe 80tpi.

Then cut the 45 deg. on the same table saw.

Use a fine tooth blade, maybe 80tpi.

Yeah I might have to make a jig. I have no problem buying router bits. I planned to buy a 15 degree hit hut couldn't figure how to use it to make the chamfer.The guide on the router may have a 15 degree setting.

Or use a shim, see 'sine table', a machinist's tool, where guage blocks or shims are used to get the correct angle for machinig.

Difficult with a hand held router.

Or you could obtain a bit / tool with the right profile...

The router doesn't have any angle settings sadly.

Well, if you are careful and take it slowly it will happen.

I've done it with smaller baffles for OB mids and it works quite ok but you need to really take your time and prepare.

Especially when your power tools, like mine, are cheap, not very precise ones.

Good luck and be very careful.

I've done it with smaller baffles for OB mids and it works quite ok but you need to really take your time and prepare.

Especially when your power tools, like mine, are cheap, not very precise ones.

Good luck and be very careful.

+2 on the careful part.

Routers must be used carefully, see if you can make a support to hold it in place .

And use a piece of wood to feed it, or plastic, never your hands.

Routers must be used carefully, see if you can make a support to hold it in place .

And use a piece of wood to feed it, or plastic, never your hands.

I think I have decided its not worth the trouble for this project. This is a decent sized enclosure and I haven't done enough finish woodworking to get it exactly how I want it.

I will assemble the box tomorrow morning. I will chamfer it then. I think if I decide I don't like it I will go at it with the hand planar and sander. Just take my time to get the shape I want.

I will assemble the box tomorrow morning. I will chamfer it then. I think if I decide I don't like it I will go at it with the hand planar and sander. Just take my time to get the shape I want.

Chris did the constructioneering, but these started out with a similar double angle bevel. Then Chris decided to make real curves.

The idea is that you are approximating a curve with an increasing radius.

This was the origial work that led to the above.

Note that your small chamfer will only have affects at the higest frequencies.

I expect 2 passes on the table saw is all it would take.

dave

The idea is that you are approximating a curve with an increasing radius.

This was the origial work that led to the above.

Note that your small chamfer will only have affects at the higest frequencies.

I expect 2 passes on the table saw is all it would take.

dave

An alternative I have thought about is what is called a "balustrade" bit for the router.

A big compound curve.

But the downside is that they are huge, need a powerful router and my mate the cabinet maker says they also need to used on a router table and not freehand

A big compound curve.

But the downside is that they are huge, need a powerful router and my mate the cabinet maker says they also need to used on a router table and not freehand

Yeah this is amazing. Beyond my current wood working skill levelChris did the constructioneering, but these started out with a similar double angle bevel. Then Chris decided to make real curves.

I did do a practice piece and succeeded with my double chamfer, however, it cause the wood to be so thin that I believe it will compromise the structure

This example you have here is definitely the way to do it. With an actual piece of wood BECOMING the chamfer.

Maybe for the next one....

Last edited by a moderator:

- Home

- Design & Build

- Construction Tips

- Help with double chamfer