Laid this out for 12x8x2. GZ34 top left, PT to right, Lundahl 1673 choke, 6SL7 center right, 2A3 bottom left, Hashimoto H-20-7U to right.

2” height should be enough room for internal components. I’m not using those polish paper-wrapped capacitors, so the electrolytics are under 35mm diameter.

I figure input in the back, shielded into 1st stage, RCA jack to front SIDE - this will be for RIGHT channel, left channel will be mirror image.

From experiences with other amps (Tektron 2A3/50IS/300b and a homebuilt 300b, it doesn’t get THAT warm inside to worry about, but I’ll leave some space around the sockets for air flow.

Any suggestions about placement, spacing? Go with a 16x8 or 17x10?

Thanks in advance.

Norm

2” height should be enough room for internal components. I’m not using those polish paper-wrapped capacitors, so the electrolytics are under 35mm diameter.

I figure input in the back, shielded into 1st stage, RCA jack to front SIDE - this will be for RIGHT channel, left channel will be mirror image.

From experiences with other amps (Tektron 2A3/50IS/300b and a homebuilt 300b, it doesn’t get THAT warm inside to worry about, but I’ll leave some space around the sockets for air flow.

Any suggestions about placement, spacing? Go with a 16x8 or 17x10?

Thanks in advance.

Norm

Attachments

@Osvaldo de Banfield

I’m a 100% disabled veteran. I just found out a few months ago I was exempt from paying property taxes here in Maryland; two years back taxes paid off some short-term debt and allowed me to buy parts like tubes, and components for this amp. The rest goes into our new home in Tennessee.

Argentina, I take it, isn’t so involved in the “free market.” I understand there are many such countries where it’s not possible to import without punitive taxation, paying off local postal workers, etc. Not sure that’s the case in Argentina.

I’m a 100% disabled veteran. I just found out a few months ago I was exempt from paying property taxes here in Maryland; two years back taxes paid off some short-term debt and allowed me to buy parts like tubes, and components for this amp. The rest goes into our new home in Tennessee.

Argentina, I take it, isn’t so involved in the “free market.” I understand there are many such countries where it’s not possible to import without punitive taxation, paying off local postal workers, etc. Not sure that’s the case in Argentina.

Hi Norm..

I was just in the same boat last year when I built these 2A3 direct-coupled monos based on the physically larger JJ 2A3-40. They are on 12" x 8" x 3" steel chassis, which have been working well and stay relatively cool, given the power tubes are cathode biased at 90ma. I initially started with 2" deep/tall chassis, but discovered that it was too little space.

Best of luck with your build. I will be following along.

I was just in the same boat last year when I built these 2A3 direct-coupled monos based on the physically larger JJ 2A3-40. They are on 12" x 8" x 3" steel chassis, which have been working well and stay relatively cool, given the power tubes are cathode biased at 90ma. I initially started with 2" deep/tall chassis, but discovered that it was too little space.

Best of luck with your build. I will be following along.

Trying not to go to polytic discussions and politicians, can you ever imagine that a good (specifically some meat and repelent for mosquito, wheels for cars, etc.) are three (3) times more expensive here than the same product manufactured in Argentina and owned in any of our bordering countries?Argentina, I take it, isn’t so involved in the “free market.” I understand there are many such countries where it’s not possible to import without punitive taxation, paying off local postal workers, etc. Not sure that’s the case in Argentina.

I have a project (partially finished) to build a full-compactron-tube amplifier with no SS at all, and DC coupled at all stages. I must stop it because electricity costs growed to a point that you need to rob a bank to pay the bill if you switch on it.

But over it, l admire the easy with all you can find parts, people that make chassis, transformers, boxes, tools to make not only fully functional, but good looking too. Some compactrons I had to import from USA, hoping no one be broken in transport, and paying for them 10 (ten) times its original post. And some time ago I knew their import theoretically is prohibited because are "dangerous" and "suspicious" elements.

In another forum I read about a guy who could find a flyback transformer for a post war tv. I couldn't get one for my PC monitor.

Hi Norm..

I was just in the same boat last year when I built these 2A3 direct-coupled monos based on the physically larger JJ 2A3-40. They are on 12" x 8" x 3" steel chassis, which have been working well and stay relatively cool, given the power tubes are cathode biased at 90ma. I initially started with 2" deep/tall chassis, but discovered that it was too little space.

Best of luck with your build. I will be following along.

[photos redacted]

You do nice work. I can see why you wanted the extra depth with the Solen caps and lowering the sockets on platorms for air flow. How do they sound?

Thanks for your kind words.

It s the building I enjoy almost as much as the music which eventually flows through them. I've been a fan of the 40W JJs for a while and wanted to try a direct-coupled iteration. The sound, even with the Hammond outputs, is sublime. The frequency response on the low end is as good as I could expect (down 1dB at 25Hz) but the top end drops off to nearly 3db at 20Hz. Square waves look almost too good to be true. Despite the measurements, I am astounded with the musicality and way they breath new life into my collection. On to the next project...

Have you settled on a design/topology for your amps? I look forward to watching your build.

It s the building I enjoy almost as much as the music which eventually flows through them. I've been a fan of the 40W JJs for a while and wanted to try a direct-coupled iteration. The sound, even with the Hammond outputs, is sublime. The frequency response on the low end is as good as I could expect (down 1dB at 25Hz) but the top end drops off to nearly 3db at 20Hz. Square waves look almost too good to be true. Despite the measurements, I am astounded with the musicality and way they breath new life into my collection. On to the next project...

Have you settled on a design/topology for your amps? I look forward to watching your build.

I started building a 300b SET in October, first sounds through it were just 2 nights ago. This was based on Skunkie Designs’ “Budget 300b” amplifier with some modifications of my own (switches, volume pot- AudioNote - coupling capacitors - Mundorf and Sons Oily silver/gold/unobtanium, Hashimoto OPT mainly). It’s parked atop a subwoofer right now (yes, it’s off when I’m using it) pending move to its permanent home in my new audio room in Tennessee sometime real soon…

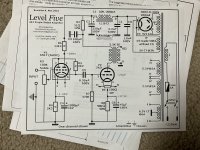

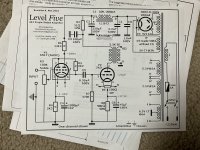

For the 2A3, I decided, after reading through I don’t know HOW many web pages, threads and several books and tube/valve experts’ writings like Morgan Jones, EJ Jurich, Aiken, Merlin Blencowe and all the commentary, opinion and blather online (you know what they say about opinions and experts), I decided to go with http://www.levelfive-audio.com/circuit.htm for design.

I’ve got pretty much all the components except the economically impossible to find ELNA Cerrafine capacitors for the power section - oh, they’re around, at around $500 EACH, used. I‘m going with AN caps instead, for now. Decided on using the Lundahl choke like so:

After redrawing Mr. Kuchinin’s schematic so I could read it left to right (ha-ha):

Why a 2A3? Why not. The ones I have sound AWESOME in a 20 year old Tektron TK2 2A3/50/300b amp and I like building stuff. I toyed with the Tektron a LOT to get rid of the 120 Hz hum while using 300b tubes. AC heaters, you know. I bought a cheap set of 2A3’s as an experiment and the buzz is almost entirely gone. I thought about putting DC heater power in there, but if I ever want to sell the amp, other than recapping and rewiring (a little, with teflon-coated 18g silver plated copper), some purists will turn up their audiophool noses without a second look. None of what I did helped remove the hum/buzz except lowering the filament voltage to 2.5VAC on the 2A3 tubes, so I bought a couple more pairs and really like how they sound.

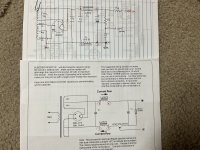

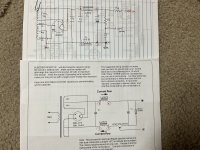

I also make these little heater power modules by close-coupling the components like so:

with about 42mm spacing between mounting holes. I’ve run heaters with them all day long and the VR (MIC39300-2.5WT) barely gets above room temperature. I mount a SMD tantalum cap across the GND and output (center) leads, flip the rectifier over so the polarity matches, and solder other components directly to the bent leads as “bus bars.” Takes up very little space, are efficient, output from this one is something like 2.4975 VDC at 3 amps with about 0.7 mVAC ripple and I’ve experimented with different caps/arrangements to try and lower that more, just not getting there. It’s inaudible in any event.

with about 42mm spacing between mounting holes. I’ve run heaters with them all day long and the VR (MIC39300-2.5WT) barely gets above room temperature. I mount a SMD tantalum cap across the GND and output (center) leads, flip the rectifier over so the polarity matches, and solder other components directly to the bent leads as “bus bars.” Takes up very little space, are efficient, output from this one is something like 2.4975 VDC at 3 amps with about 0.7 mVAC ripple and I’ve experimented with different caps/arrangements to try and lower that more, just not getting there. It’s inaudible in any event.

Why a metal case? That hard maple took weeks for me to fabricate (drilling the 1/8” carbon steel sheet was a real bear) but it matches a plinth I made for a Thorens TD125 Mk2 turntable (THAT took some time, too), so I think what I’m going to do is just rout out some 5/8” maple end-caps for the metal cases, with about a 1/4” overlap on each side, since, like you, I’ll have the control and power/input ends front and back respectively, power switch location I haven’t decided on yet. Yeah, Hammond makes Walnut panels for their chassis’… I only like Walnut on gunstocks and pistol grips and everything else like the Salamander archetype stand is maple except for the Tektron which is Olive wood..

For the 2A3, I decided, after reading through I don’t know HOW many web pages, threads and several books and tube/valve experts’ writings like Morgan Jones, EJ Jurich, Aiken, Merlin Blencowe and all the commentary, opinion and blather online (you know what they say about opinions and experts), I decided to go with http://www.levelfive-audio.com/circuit.htm for design.

I’ve got pretty much all the components except the economically impossible to find ELNA Cerrafine capacitors for the power section - oh, they’re around, at around $500 EACH, used. I‘m going with AN caps instead, for now. Decided on using the Lundahl choke like so:

After redrawing Mr. Kuchinin’s schematic so I could read it left to right (ha-ha):

Why a 2A3? Why not. The ones I have sound AWESOME in a 20 year old Tektron TK2 2A3/50/300b amp and I like building stuff. I toyed with the Tektron a LOT to get rid of the 120 Hz hum while using 300b tubes. AC heaters, you know. I bought a cheap set of 2A3’s as an experiment and the buzz is almost entirely gone. I thought about putting DC heater power in there, but if I ever want to sell the amp, other than recapping and rewiring (a little, with teflon-coated 18g silver plated copper), some purists will turn up their audiophool noses without a second look. None of what I did helped remove the hum/buzz except lowering the filament voltage to 2.5VAC on the 2A3 tubes, so I bought a couple more pairs and really like how they sound.

I also make these little heater power modules by close-coupling the components like so:

with about 42mm spacing between mounting holes. I’ve run heaters with them all day long and the VR (MIC39300-2.5WT) barely gets above room temperature. I mount a SMD tantalum cap across the GND and output (center) leads, flip the rectifier over so the polarity matches, and solder other components directly to the bent leads as “bus bars.” Takes up very little space, are efficient, output from this one is something like 2.4975 VDC at 3 amps with about 0.7 mVAC ripple and I’ve experimented with different caps/arrangements to try and lower that more, just not getting there. It’s inaudible in any event.

with about 42mm spacing between mounting holes. I’ve run heaters with them all day long and the VR (MIC39300-2.5WT) barely gets above room temperature. I mount a SMD tantalum cap across the GND and output (center) leads, flip the rectifier over so the polarity matches, and solder other components directly to the bent leads as “bus bars.” Takes up very little space, are efficient, output from this one is something like 2.4975 VDC at 3 amps with about 0.7 mVAC ripple and I’ve experimented with different caps/arrangements to try and lower that more, just not getting there. It’s inaudible in any event.Why a metal case? That hard maple took weeks for me to fabricate (drilling the 1/8” carbon steel sheet was a real bear) but it matches a plinth I made for a Thorens TD125 Mk2 turntable (THAT took some time, too), so I think what I’m going to do is just rout out some 5/8” maple end-caps for the metal cases, with about a 1/4” overlap on each side, since, like you, I’ll have the control and power/input ends front and back respectively, power switch location I haven’t decided on yet. Yeah, Hammond makes Walnut panels for their chassis’… I only like Walnut on gunstocks and pistol grips and everything else like the Salamander archetype stand is maple except for the Tektron which is Olive wood..

@tubelectron

Thank you. Beautiful work.

That speaks volumes.

Speaking of which, I think the 12x8x3 is the way to go… I have no plans for installing a cooling fan. 😉

Thank you. Beautiful work.

That speaks volumes.

Speaking of which, I think the 12x8x3 is the way to go… I have no plans for installing a cooling fan. 😉

@tubelectron

Thank you. Beautiful work.

That speaks volumes.

Speaking of which, I think the 12x8x3 is the way to go… I have no plans for installing a cooling fan. 😉

Thanks @NormB ! 🙂

Yes, I built my amps as compact as possible - these above are "large amplifiers", these below are "small amplifiers" :

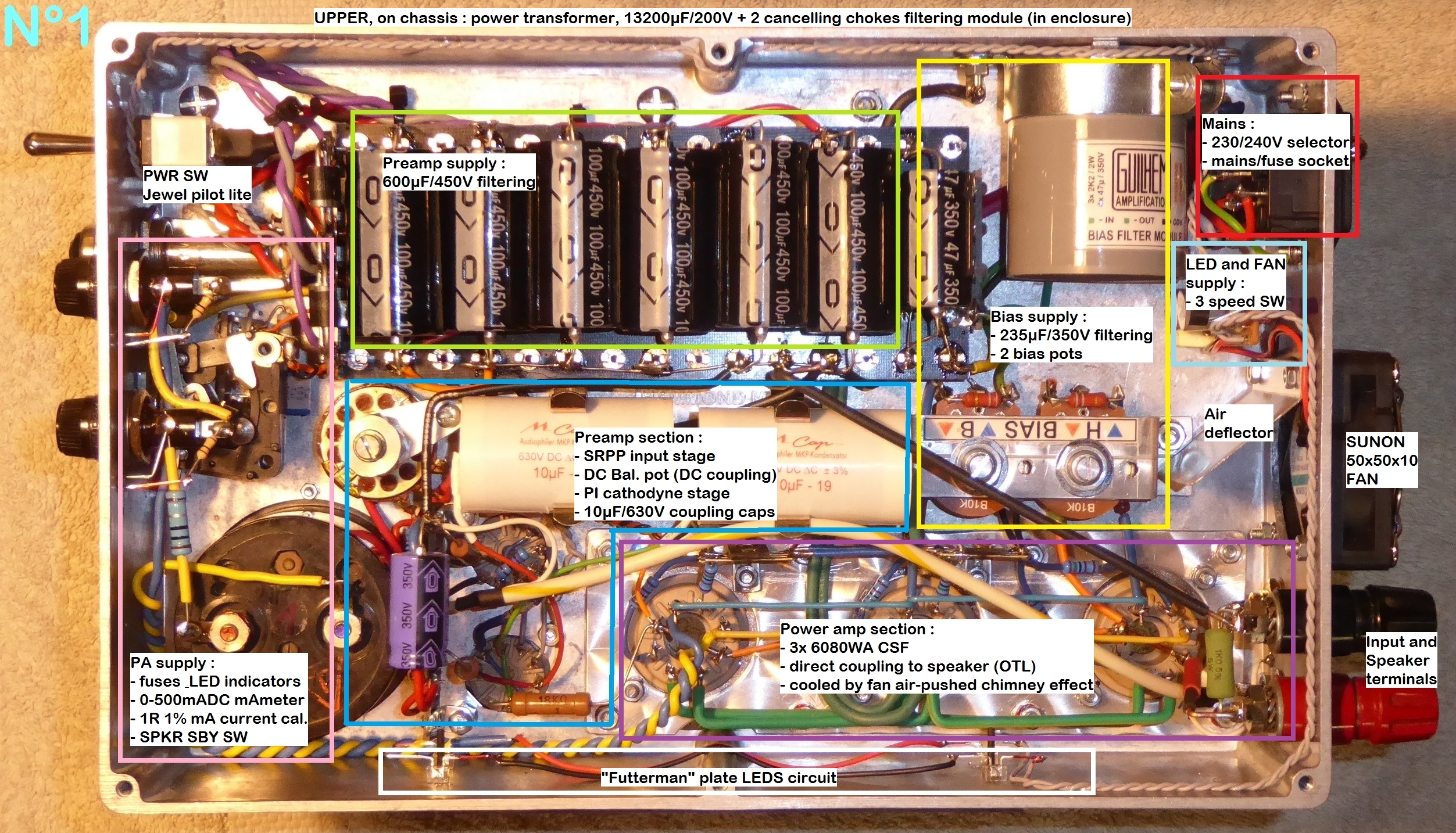

Note that among my "large amplifiers", only one model is fitted wit a fan : the U-OTL6080, in order to cool by chimney effect the 6080WA with a light and silent air flow, provided by a reduced speed fan...

T

I like compact. If I had it to do all over again I think I could make the two-channel amp about 80% its current size and an inch shorter, but it’s not a bad first effort.

Space heaters needn’t be so big. 🤣

Space heaters needn’t be so big. 🤣

I like compact. If I had it to do all over again I think I could make the two-channel amp about 80% its current size and an inch shorter, but it’s not a bad first effort.

Space heaters needn’t be so big. 🤣

Sure ! Just about my U-OTL6080, the temperature at the top of the bulb of the 6080WA reaches and stabilizes at 190°C after 5 minutes of operation, with the cooling fan at low speed :

T

Not to hijack this thread, but doesn't the emissivity of the material measured with a IR thermometer affect the readings? Glass bulb vs a flat black transformer for instance.

Infra-red emissivity is a direct function of temperature, so what you measure is temperature at the considered point. I mean, concerning a tube : you do not have the same temperature at the base of the bulb than at the top, and also if you are pointing a cathode or a getter.

T

Interesting, my infrared thermometer allow one to alter the settings to allow for different emissivity. I'll back out now as the thread is Interesting without me further mucking it up.

Interesting, my infrared thermometer allow one to alter the settings to allow for different emissivity. I'll back out now as the thread is Interesting without me further mucking it up.

That said, my Fluke thermometer (see my measurement picture above) has a button called EMS at the right... I never took care of it : maybe I should ! 🤔 😉

T

- Home

- Amplifiers

- Tubes / Valves

- 2A3 monoblock chassis size question