Hi

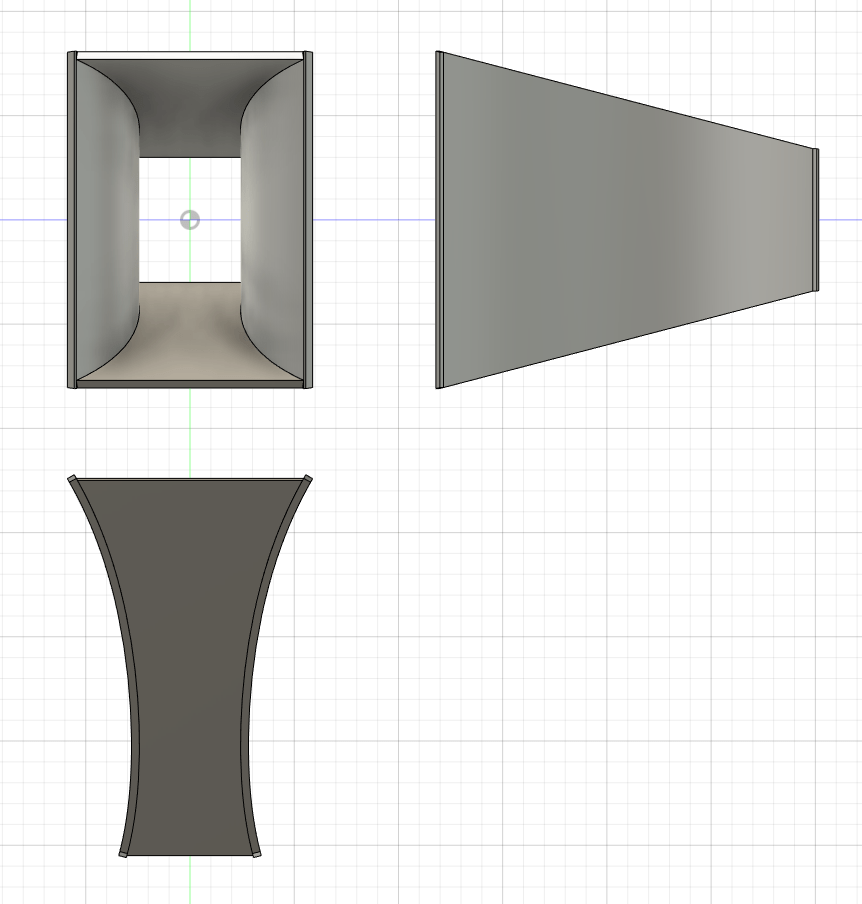

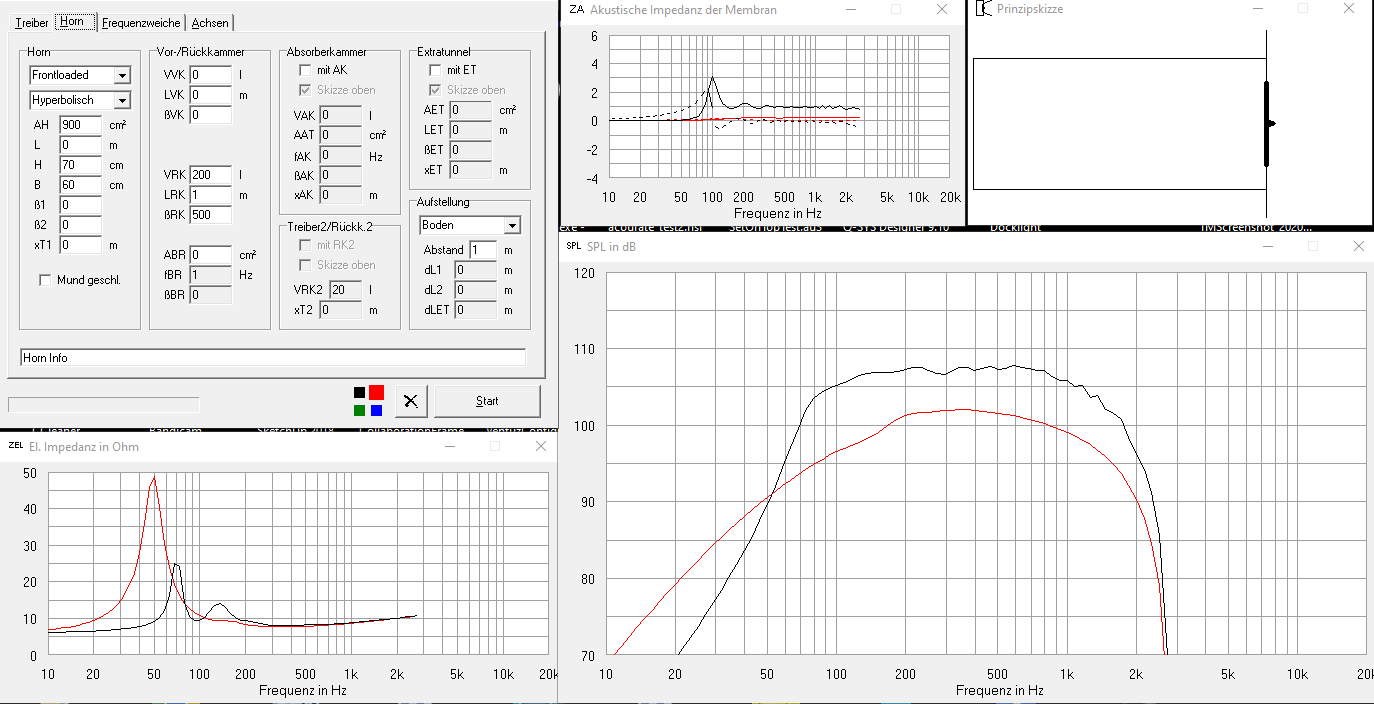

i am trying to construct a hyperbolic front horn. To make the construction as easy as possible, i would like to build top and bottom straight and just curve the sides.

Is it a problem, if the sidewalls get curve that way, that the distance is first getting smaller? Area will be conform to the calculated area.

Even if the 3D sketch is not 100% correct, it shows my problem:

Thanks and regards

Christian

i am trying to construct a hyperbolic front horn. To make the construction as easy as possible, i would like to build top and bottom straight and just curve the sides.

Is it a problem, if the sidewalls get curve that way, that the distance is first getting smaller? Area will be conform to the calculated area.

Even if the 3D sketch is not 100% correct, it shows my problem:

Thanks and regards

Christian

If you want the Hornresp response, you better follow the drawing. My guess is that this is not a good idea....

//

//

Thx for the answer, but: the drawing from AJ-Horn is just showing 2D not 3D.

What i thought is, the it is important to follow the cm²/cm in depth, what i am doing. what means: by cm² the horn is always opening.

But this is no really valid knowing 😉

What i thought is, the it is important to follow the cm²/cm in depth, what i am doing. what means: by cm² the horn is always opening.

But this is no really valid knowing 😉

The narrowing would be fine from a loading perspective. It's usual for these to narrow that way when you make one dimension conical.

The question is, what is this horn for? Where do you draw your line between horn loading and waveguiding.

The question is, what is this horn for? Where do you draw your line between horn loading and waveguiding.

Christian,

As long as the cross sectional area conforms to the calculated area the horn should perform like the simulation.

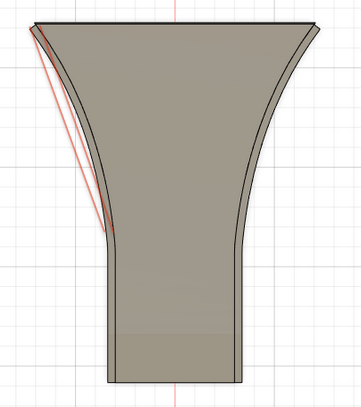

Using two straight side pieces, making the second portion as in the red lines above will make very little difference in the response, and will avoid the pain and suffering of laminating and bending plywood..

Unlike my suggestion in your ElectroVoice HP6040 MEH experiment, I have a lot of actual experience in building and comparing mid-bass horns with and without the side curves to base the above statement on 😉 .

Art

As long as the cross sectional area conforms to the calculated area the horn should perform like the simulation.

Using two straight side pieces, making the second portion as in the red lines above will make very little difference in the response, and will avoid the pain and suffering of laminating and bending plywood..

Unlike my suggestion in your ElectroVoice HP6040 MEH experiment, I have a lot of actual experience in building and comparing mid-bass horns with and without the side curves to base the above statement on 😉 .

Art

Thx for the answers!

Allen:

Will use it between 90Hz and 300Hz.

Hi Art

Allen:

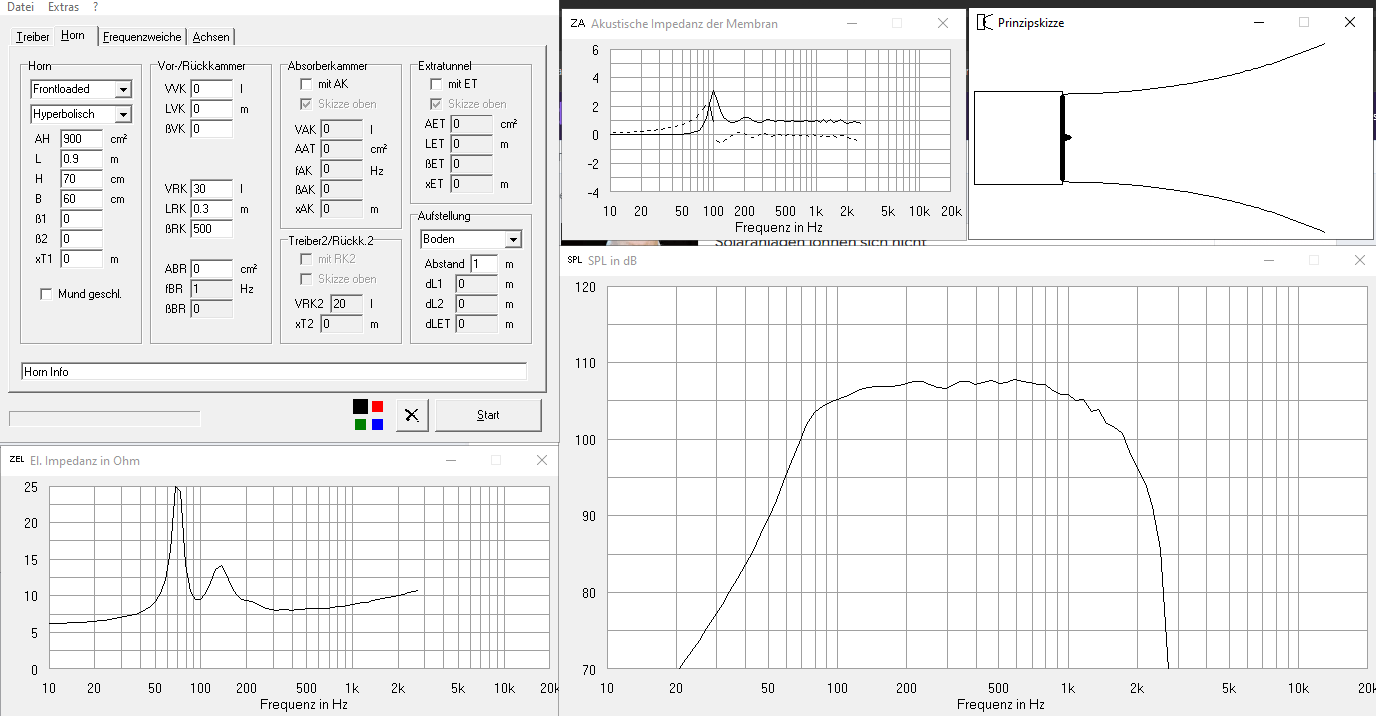

In red you can see the simulation with the same driver in a 200L closed Box. I know, for many people the Horn is to small, to call it a horn... but ~6dB to 10dB gain an lower cut off is it worth... isn't it?The question is, what is this horn for? Where do you draw your line between horn loading and waveguiding.

Will use it between 90Hz and 300Hz.

Hi Art

Glad, that you remember me!Unlike my suggestion in your ElectroVoice HP6040 MEH experiment,

Yes... will build it straight, but maybe, i will cnc some curved plates for filling up the not bended area 😉Using two straight side pieces, making the second portion as in the red lines above will make very little difference in the response, and will avoid the pain and suffering of laminating and bending plywood..

Those with straight sides are WGs, curved are horns.The question is, what is this horn for? Where do you draw your line between horn loading and waveguiding.

Attachments

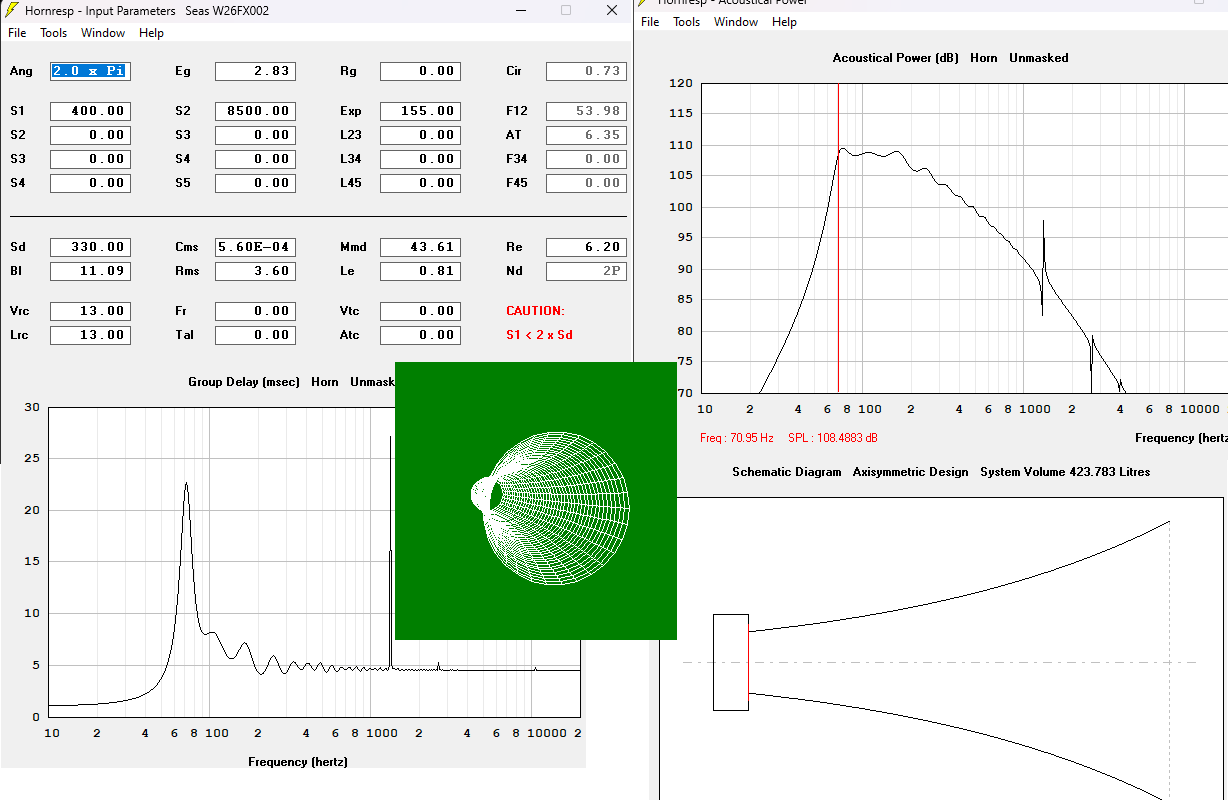

I made an interesting horn design in Hornresp just now. Trying to make better use of my four Seas W26FX002 that are currently housed in sealed 60L boxes, two in each.

The size of this horn is quite modest compared to my usual late night designs, but creates a nice midbass channel from 70-200Hz. The drivers are not your typical low QTS speaker drivers, but I can assure that they are smooth and likes playing midbass. Magnet motor is reasonably strong.

A square horn might gain strength from the floor compared to a round horn. and I might use a version of your design for easy assembly.

I would love to keep them in their enclosures and just reduce the volume in the cabinets and add the horn.

It is not like they are producing much bass now anyway.

Sorry for stealing thread, I just thought our projects were similar.

The size of this horn is quite modest compared to my usual late night designs, but creates a nice midbass channel from 70-200Hz. The drivers are not your typical low QTS speaker drivers, but I can assure that they are smooth and likes playing midbass. Magnet motor is reasonably strong.

A square horn might gain strength from the floor compared to a round horn. and I might use a version of your design for easy assembly.

I would love to keep them in their enclosures and just reduce the volume in the cabinets and add the horn.

Sorry for stealing thread, I just thought our projects were similar.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- MidBass Horn