Planning my first non-trivial speaker build and would love any critique of my plan. Looking for a general all-arounder that lets me play with active xovers and a big multicell horn. I have lots of amps and different speakers but this would be my first foray into a more complex build. I have Klipsch Cornwall IVs as far as horn experience goes, other than that all of my systems have been full range or multiway standard drivers. So far my plan is:

Onken bass box

Thanks for any tips on matching or other things!

Onken bass box

- Great Plains Audio 416-8b (here)

- Cabinet based on plans from Joseph Crowe (here)

- Industrial/basic style finish with exposed stainless hardware in most places

- Dayton speaker binding posts (here) mounted on plates (here)

- Belden 9747 internal wiring, soldered with silver solder

- Great Plains Audio 288-8k (though it seems like they might have stopped making them?)

- 1505b wood horn from Marcus Klug (here)

- some sort of custom sled made from allthread

- 1000Hz done with active box, either my current Lyngdorf or a future Driverack or similar -- will experiment

- amps -- will experiment

- will not add at first, maybe in the future

Thanks for any tips on matching or other things!

Onken bass box

[*]Cabinet based on plans from Joseph Crowe

Note that he is using a max-flat alignment as opposed to the historical/traditional Onken tuning.

complex build

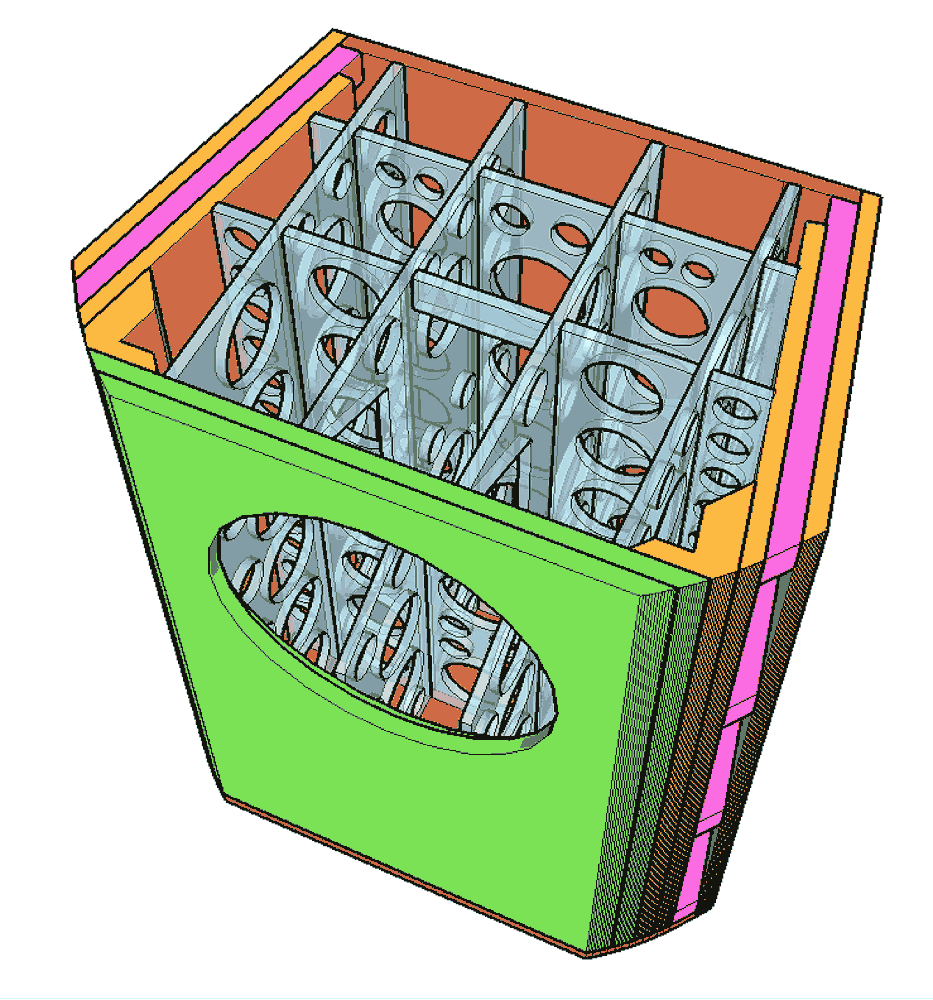

Not really. Joseph doesn’t show his bracing so i can’t comment on that, this Monster miniOnken i did for the TAD 401 is complex.

[*]Dayton speaker binding posts

Too much metal for my taste.

[*]Belden 9747 internal wiring, soldered with silver solder

Really?

You are spending BIG bucks on the GPA, and quality plywood for 200 litres of properly braced Onken enclosure is going to be a pretty penny, but cheaping out on these?

I would suggest some ETI or WBT NextGen posts, and people may argue about suitable wire thickness but use something decent. I would use 1 or more pairs of this stuff: https://www.takefiveaudio.com/products/907-neotech-upocc-24-awg-teflon-insulation-cryo-treated/

Electronics

[*]1000Hz done with active box,

Crossover? That high? A challenge for most 15”

dave

Yeah, original is 270 L/~8.58 ft^3 net. Re connectors, 'smart money' is equal length speaker wiring hard wired with proper cold weld connectors at the amp.

Indeed! Altec used 300, 500, 800 Hz/2nd for 15" woofers depending on the needs of the app with 1000-1200 Hz limited to duplex drivers.

Indeed! Altec used 300, 500, 800 Hz/2nd for 15" woofers depending on the needs of the app with 1000-1200 Hz limited to duplex drivers.

Thanks for the reply! By this you mean just run the wires straight through the cabinet without any connectors in the back panel, just connectors at the amp end? With RTV silicone or something to make the pass-through air tight?Yeah, original is 270 L/~8.58 ft^3 net. Re connectors, 'smart money' is equal length speaker wiring hard wired with proper cold weld connectors at the amp

TAD TL-1601A or B ? 🙃TAD 401

As for the OP, what is the reasoning for 24 and 22 AWG wiring for a bass driver?

That is what is used every day, for 1-4 watt loads at 24V traditionally.

Just adds resistive losses and heating of conductors.

Spend more on cross section, less on 'fancy marketing materials 🙂

Last edited:

TAD TL-1601A or B ?

Oops, the 401 the compression driver?

1601A, the client is using them with Yuchi on the top. I’d use something like Alpair 10PeN in a midTL between the bass drivers. Or maybe a LeCleac’h horn.

Just adds resistive losses

Or fix an issue with an over damped amplifier? And i suggested you might use multiples.

dave

- Home

- Loudspeakers

- Multi-Way

- Help me finalize my build plan? Onken cab with multicell horn.