Prevailing design these days is for the rounding over of everything on the front baffle, commonly blending into a waveguide as wide as the woofer. I find this unbearably ugly. While considering the details for my current project (small 10l cabinet nearfields) I'm wondering a) how significant a difference this makes and b) are there any other options to the rounded over and smushed out.

If i put a flat 45 degree chamfer around the baffle edge, instead of rounded edges, what is the actual effect it is going to have? a wobble in the response of maybe 1-2db? or is it something more magnificent? the somewhat famous LS35a design had a thick ring of felt around the tweeter to prevent the wavefront even encountering the edge of the baffle. Is something like this a valid option? You don't see this approach being taken these days. Another thing you don't see are those odd JBL accoustic lenses, even they looked better than waveguides, just.

I suppose i am hoping for a cool looking 3d printable metamaterial lens or something 😀

If i put a flat 45 degree chamfer around the baffle edge, instead of rounded edges, what is the actual effect it is going to have? a wobble in the response of maybe 1-2db? or is it something more magnificent? the somewhat famous LS35a design had a thick ring of felt around the tweeter to prevent the wavefront even encountering the edge of the baffle. Is something like this a valid option? You don't see this approach being taken these days. Another thing you don't see are those odd JBL accoustic lenses, even they looked better than waveguides, just.

I suppose i am hoping for a cool looking 3d printable metamaterial lens or something 😀

The odd JBL accoustic lenses may look better to you, but don't measure near as well as decent waveguides.

Hard to give any hard and fast answers without knowing the dispersion patterns of the drivers you are using, where they are located on the baffle, and the size of the baffle.

Felt can reduce the "ripple" by +/-2dB.

https://www.speakerdesign.net/audioXpress/diffraction/diffraction.html

Hard to give any hard and fast answers without knowing the dispersion patterns of the drivers you are using, where they are located on the baffle, and the size of the baffle.

Felt can reduce the "ripple" by +/-2dB.

https://www.speakerdesign.net/audioXpress/diffraction/diffraction.html

If i put a flat 45 degree chamfer around the baffle edge, instead of rounded edges

A 45° bevel gives a larger effective radius than a round over in the same space. Given that what is usually added to most builds is not really large enuff every little bit helps.

You can soften the corners to make it look a bit better and it might be a small.

Same box one, with sharp edges, one with them softened.

dave

I'm not sure if you're asking about general baffle roundovers or if it's specifically about waveguide/baffle geometry.

When it comes to baffle edge rounding, a lot of what is done is too small to do what's desired (as planet10 beat me to saying). Things like the old Thiel or Hales designs that used like 3" round-overs were more like it.

Not exactly what you're asking (I don't think), but some data on baffle geometry and acoustic results here:

http://www.troelsgravesen.dk/stepped-baffle.htm

When it comes to baffle edge rounding, a lot of what is done is too small to do what's desired (as planet10 beat me to saying). Things like the old Thiel or Hales designs that used like 3" round-overs were more like it.

Not exactly what you're asking (I don't think), but some data on baffle geometry and acoustic results here:

http://www.troelsgravesen.dk/stepped-baffle.htm

Remember a "joke" made by a Ferrari person: "Aerodynamics are for people who can't build engines".

Ergo: "Rounded edges are for people who can't design x/o filters".

Of course, aerodynamics are completely different ballgame.

Ergo: "Rounded edges are for people who can't design x/o filters".

Of course, aerodynamics are completely different ballgame.

Hahahaha......that is funny....Like the aerodynamic for the humblebee"Aerodynamics are for people who can't build engines".

Coffee break philosphy:

Aesthetics and sound quality are two very high level goals, or the lowest possible level buckets to contain all sorts of things, and often odds with each other. Another big buckets I have figured out are size and cost. Now, put all these in order of importance, and then when ever you have a compromise to decide on, base your decision on the priority list. Now making a project is a breeze and you'll end up with success. The minute you start to break your priority list the project becomes random success, non-optimal compromise 😀

Example, if your order of importance is aesthetics, sound quality, size, cost, you could end up with a golden shoebox or some decorative figurino per your taste and since aesthetics is priority number 1. you'd get what you wanted, with some penalty on sound quality and more on size and cost. Or, if your priority is cheap cost and small size being most important, it is then easy to understand expectation off audio quality and aesthetics has to be cut down. You could think it conversely as well, to get better audio quality be ready to sacrifice aesthetics or vice versa. Even more simpified, if you want to make best speakers ever you must prioritize audio quality over everything else, or you are not going to get it, simple as that. If you want to make shiny objects to look at, do they have to make sound in the first place?

It's important to understand everything is a compromise and no matter how much one wishes to have everything best it's not gonna happen. If you want square box, then accept the sound isn't top notch and that's fine, it's likely gonna be just fine, you chose aesthetics over sound quality, be happy with it.

ps. design best speakers in the world with the priority list, and after the design is done you can then optimize it: you might be able to circumvent aesthetics by making speakers practically invisible which might make the size irrelevant. Also cost doesn't have to be expensive, it can be minimized 😉

Aesthetics and sound quality are two very high level goals, or the lowest possible level buckets to contain all sorts of things, and often odds with each other. Another big buckets I have figured out are size and cost. Now, put all these in order of importance, and then when ever you have a compromise to decide on, base your decision on the priority list. Now making a project is a breeze and you'll end up with success. The minute you start to break your priority list the project becomes random success, non-optimal compromise 😀

Example, if your order of importance is aesthetics, sound quality, size, cost, you could end up with a golden shoebox or some decorative figurino per your taste and since aesthetics is priority number 1. you'd get what you wanted, with some penalty on sound quality and more on size and cost. Or, if your priority is cheap cost and small size being most important, it is then easy to understand expectation off audio quality and aesthetics has to be cut down. You could think it conversely as well, to get better audio quality be ready to sacrifice aesthetics or vice versa. Even more simpified, if you want to make best speakers ever you must prioritize audio quality over everything else, or you are not going to get it, simple as that. If you want to make shiny objects to look at, do they have to make sound in the first place?

It's important to understand everything is a compromise and no matter how much one wishes to have everything best it's not gonna happen. If you want square box, then accept the sound isn't top notch and that's fine, it's likely gonna be just fine, you chose aesthetics over sound quality, be happy with it.

ps. design best speakers in the world with the priority list, and after the design is done you can then optimize it: you might be able to circumvent aesthetics by making speakers practically invisible which might make the size irrelevant. Also cost doesn't have to be expensive, it can be minimized 😉

If you have a waveguide, the baffle edges are less important. Note that KEF have gone for sharper edges on their cabinets recently and introduced that 'shadow ring' thing. Certainly a chamfer is a good alternative to a round over.

Remember a "joke" made by a Ferrari person: "Aerodynamics are for people who can't build engines".

Ergo: "Rounded edges are for people who can't design x/o filters".

Of course, aerodynamics are completely different ballgame.

Unfortuneately the analogy is not valid. A good XO will not fix a diffraction issue.

dave

Certainly a chamfer is a good alternative to a round over.

It is, a better one IMO if you don’t have ≈10cm+ of roundover.

dave

@weltersys very interesting link, certanly worth considering then!

@planet10 Nice system, is that yours? 😀 Yeah those are much larget chamfers than i was planning.

@mattstat interesting link, yes it does seem you need a large edge rounding/chamfer to have an effect

@Lojzek HAH! I'm planning a digital XO. correcting for every rise and fall in the responce is stil going to be a chalenge. and it won't fix difraction problems anyway i think.

@tmuikku Well, yes. 😀 I'm just trying to avoid unexpected pitfalls and dead ends in the sound quality area by drawing on the hive mind's collective experance 😉

@Tenson hmm that shadow ring is an interesting design. a bit of googling suggests it's super sensitive to positioning and presumably design. big dips in response if it's even just 1mm too far out. probably because it's compellarly concentric around the driver, not offset. somthing to think about though. I wonder if a thick ring of multiple small pointy spikes adound the driver would achieve a similar thing, breaking up the wavefront so it never reaches the edge without the need for such precise design/implimentation

@planet10 Nice system, is that yours? 😀 Yeah those are much larget chamfers than i was planning.

@mattstat interesting link, yes it does seem you need a large edge rounding/chamfer to have an effect

@Lojzek HAH! I'm planning a digital XO. correcting for every rise and fall in the responce is stil going to be a chalenge. and it won't fix difraction problems anyway i think.

@tmuikku Well, yes. 😀 I'm just trying to avoid unexpected pitfalls and dead ends in the sound quality area by drawing on the hive mind's collective experance 😉

@Tenson hmm that shadow ring is an interesting design. a bit of googling suggests it's super sensitive to positioning and presumably design. big dips in response if it's even just 1mm too far out. probably because it's compellarly concentric around the driver, not offset. somthing to think about though. I wonder if a thick ring of multiple small pointy spikes adound the driver would achieve a similar thing, breaking up the wavefront so it never reaches the edge without the need for such precise design/implimentation

The shadow ring really is just a continuation of the tweeter waveguide formed by the midrange cone. You can see the cone and shadow ring as a single waveguide that increases directionality of the tweeter and thus reduces how much sound reaches the baffle edges.

Spikes or things like that around the driver could scatter the sound so there is less of a single strong reflection but this is kind of a band-aid compared to simply increasing the directivity of the driver to avoid the issue.

Spikes or things like that around the driver could scatter the sound so there is less of a single strong reflection but this is kind of a band-aid compared to simply increasing the directivity of the driver to avoid the issue.

@planet10 Nice system, is that yours? 😀 Yeah those are much larget chamfers than i was planning.

Yes, at one point in time anyway. Chris built the first ones, Bernie that latter (solid western red cedar, he built my personal pair out of solidYew). They are tiny, disapear in the room and stun people when they listen to these “computer” loudspeaker in the big system. Add a helper woofer and they give up little (ultimat elevels and some dynamics).

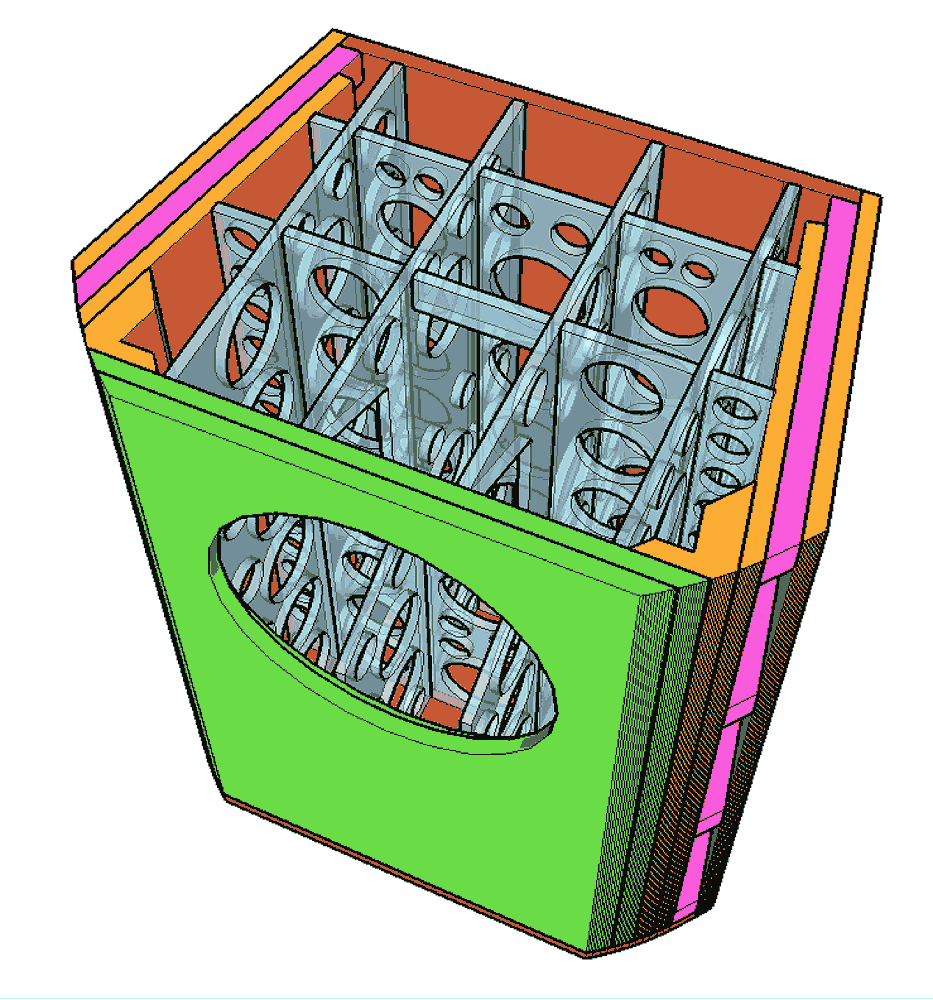

The largish chamfers can be seen in all of the trapezoid miniOnkens. Fronm the little 2.5 litre ones above to this 135 litre bass enclosure.

The taper towards the back extends the chamfer around the back, and makes for a subtle improvement over the rectangular ones:

And a very noticeable improvement oibver the same alignment in the pretty much rectangular CGR.

dave

Last edited:

I'm wondering ..........

If i put a flat 45 degree chamfer around the baffle edge, instead of rounded edges, what is the actual effect it is going to have? a wobble in the response of maybe 1-2db? or is it something more magnificent

dont wonder - put the tweeter flush on a large baffle and measure it - that is the baseline - now build a test baffle and check

Just get speaker fabric with a print of your favorite commercial speaker...

Prevailing design these days is for the rounding over of everything on the front baffle, commonly blending into a waveguide as wide as the woofer. I find this unbearably ugly. While considering the details for my current project (small 10l cabinet nearfields) I'm wondering a) how significant a difference this makes and b) are there any other options to the rounded over and smushed out.

If i put a flat 45 degree chamfer around the baffle edge, instead of rounded edges, what is the actual effect it is going to have? a wobble in the response of maybe 1-2db? or is it something more magnificent? the somewhat famous LS35a design had a thick ring of felt around the tweeter to prevent the wavefront even encountering the edge of the baffle. Is something like this a valid option? You don't see this approach being taken these days. Another thing you don't see are those odd JBL accoustic lenses, even they looked better than waveguides, just.

I suppose i am hoping for a cool looking 3d printable metamaterial lens or something 😀

I agree totally with you about aesthetics @sigmatechnica ! It's also an important point for me...

According to Vance Dickason's Loudspeaker Cook Book, rounded or chamfered edge cabinets brings no noticeable changes until they measure more than 2".

Personally I do not care too much about this, I never noticed significant differences at least in near field listening...

Below, the edge radiuses are 6.3mm (1/4") :

While these ones have a 12.7mm radius (1/2") :

All are made from Glulam Beechwood, and the first two have their frontface covered with simili.

T

- Home

- Loudspeakers

- Multi-Way

- Aesthetics vs acoustic perfection