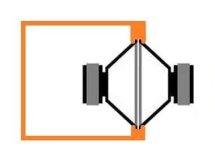

Can we damp space between the 2 cones in a clamshell- type isobaric woofer?

We've already modelled and measured the response of two very similar(not identical) 12" woofers used face-to-face in a stuffed 1.5ft3 sealed box.

We initially have a box fc of around 40hz with a Qtc of about 0.8.

Would it be useful to put polyester stuffing/ wadding or maybe lightweight foam in the cavity between the woofers cones (or must it be empty)?

This might add a small increase in moving mass(7% to 10%), and maybe offer some damping of any cavity resonance that may exist in the space between the two cones(?)

(...or is this a solution in search of a problem?)

Any insights or experience related to these questions?

Thanks

-Chas

We've already modelled and measured the response of two very similar(not identical) 12" woofers used face-to-face in a stuffed 1.5ft3 sealed box.

We initially have a box fc of around 40hz with a Qtc of about 0.8.

Would it be useful to put polyester stuffing/ wadding or maybe lightweight foam in the cavity between the woofers cones (or must it be empty)?

This might add a small increase in moving mass(7% to 10%), and maybe offer some damping of any cavity resonance that may exist in the space between the two cones(?)

(...or is this a solution in search of a problem?)

Any insights or experience related to these questions?

Thanks

-Chas

Last edited:

Can we damp space between the 2 cones in a clamshell- type isobaric woofer?

I have always done so. The chamber works at LF, damping helps kill any extraneous HF.

dave

A design I just took notice of had one sealed chamber with two drivers in a baffle panel, one fwd driven, one reversed. Then another chamber encompassing those two with a passive radiator.

I wondered how the two drivers wouldn’t just cancel each other’s movements, however it appears to work in this arrangement.

Something like that may have a similar effect, with the the use of the radiator.

I wondered how the two drivers wouldn’t just cancel each other’s movements, however it appears to work in this arrangement.

Something like that may have a similar effect, with the the use of the radiator.

I've lined the middle compartment with 1/2" thick PU foam on the inside walls.

This may be a little OT, but I also use a temp sensor in the main inside enclosure cavity to monitor VC temp and power compression. I clamp it to the basket near the spider opening. That area heats up fast and I wish there was a way to vent it without causing a loss in the tuning.

This may be a little OT, but I also use a temp sensor in the main inside enclosure cavity to monitor VC temp and power compression. I clamp it to the basket near the spider opening. That area heats up fast and I wish there was a way to vent it without causing a loss in the tuning.

Thanks DaveI have always done so. The chamber works at LF, damping helps kill any extraneous HF.

dave

What material did you use in the cavity between the cones, and how did you determine how much to use?

Thanks

The urethane foam is a little easier to contain IMO, as it doesn't start shedding at higher SPLs. I guess if you glue it down well enough, there's no issue, but stapling it alone isn't enough to keep it from coming loose.

A cover layer of grille cloth stretched and stapled over the FG keeps it in place without any little pieces coming loose and bouncing around in the cavity.

A cover layer of grille cloth stretched and stapled over the FG keeps it in place without any little pieces coming loose and bouncing around in the cavity.

Thanks, Dave

I'm allergic to F.G., so I'll use enough dacron wadding that it will stay against the cones, in sync without balling up and rattling about.

Profiguy, I believe you misread my original post. I'm interested in stuffing the cavity between two face-to-face woofers, so stapling isn't an option, but thanks for contributing anyway. 🙂

I'm allergic to F.G., so I'll use enough dacron wadding that it will stay against the cones, in sync without balling up and rattling about.

Profiguy, I believe you misread my original post. I'm interested in stuffing the cavity between two face-to-face woofers, so stapling isn't an option, but thanks for contributing anyway. 🙂

Attachments

dacron wadding

If it is not in a sheet i would put it in a “bag”.

dave

One More Question:

(Just remembered to ask)

If the added material between the cones increases net Mms by about 5-10%, will that have any appreciable effect on Fb, Qtc, and sensitivity (i.e. is any advantage offset by reduced woofer performance)?

Thanks.

(Just remembered to ask)

If the added material between the cones increases net Mms by about 5-10%, will that have any appreciable effect on Fb, Qtc, and sensitivity (i.e. is any advantage offset by reduced woofer performance)?

Thanks.

Last edited:

Also, stuffing recommendations for fiberfill are ~16oz per cubic foot of enclosure volume. My calculations indicate the empty space between the cones is a volume of roughly 90 in3 (~45 in3 per cone).

1728÷90=~20

16(oz)÷20=~0.8, roughly about

3/4 oz of fiberfill which, in an uncompressed clump, is about the size of a regulation soccer ball and can be squished into a "torus" to fit cone cavity snugly.

Sound about right?

(Or should I avoid compressing the dacron so much)

Thanks.

1728÷90=~20

16(oz)÷20=~0.8, roughly about

3/4 oz of fiberfill which, in an uncompressed clump, is about the size of a regulation soccer ball and can be squished into a "torus" to fit cone cavity snugly.

Sound about right?

(Or should I avoid compressing the dacron so much)

Thanks.

Attachments

Last edited:

Thanks Dave.

Please Help me to understand-

I can cut the 9" ball in half and that's good as the resulting hemisphere with a hole in the center's easier to shape to fit volume(w/o compression). The torus will now have 1/2 the above mass and density.

If it's much less I'm concerned with it moving around in anti-phase to the cones. I need it to fill the space.

Also, how do YOU use the fiberglass between two cones without it touching one or both?

Thanks.

Please Help me to understand-

I can cut the 9" ball in half and that's good as the resulting hemisphere with a hole in the center's easier to shape to fit volume(w/o compression). The torus will now have 1/2 the above mass and density.

If it's much less I'm concerned with it moving around in anti-phase to the cones. I need it to fill the space.

Also, how do YOU use the fiberglass between two cones without it touching one or both?

Thanks.

Last edited:

my original thought was to replace the air mass with a light physical mass (Dacron), Since the two woofer cones move in unison and are there for considered as a single moving mass.

Looks from the illustration as though the damping material is in contact with both cone faces. If not, by what force do you keep it from contacting the cone faces, while still being a part of the moving mass, as opposed to a stationary damping membrane (against which the surrounds would vibrate)?

Thanks

p.s.

The principle of the isobaric loading, I believe, is to keep the volume of air between the woofers constant and moving with them. A damping membrane that is fixed to the frame would seem to alter the dynamics of that system(almost like an aperiodic element?)

Looks from the illustration as though the damping material is in contact with both cone faces. If not, by what force do you keep it from contacting the cone faces, while still being a part of the moving mass, as opposed to a stationary damping membrane (against which the surrounds would vibrate)?

Thanks

p.s.

The principle of the isobaric loading, I believe, is to keep the volume of air between the woofers constant and moving with them. A damping membrane that is fixed to the frame would seem to alter the dynamics of that system(almost like an aperiodic element?)

Attachments

Last edited:

"As i said, put it in a bag"

Would you please describe how you mount the bag between the woofers in a way that allows it to move with the cones as part of the overall mass, and without the surrounds touching it?

Sorry, I just can't picture it. :-(

Also, why can't the dacron touch the cones, since they are moving together with the enclosed air as a single moving mass already? It seems we could almost inject urethane foam into that cavity but Dacron has far less mass.

Thanks for your patience- I'm trying to wrap my brain around all of this. :-(

Would you please describe how you mount the bag between the woofers in a way that allows it to move with the cones as part of the overall mass, and without the surrounds touching it?

Sorry, I just can't picture it. :-(

Also, why can't the dacron touch the cones, since they are moving together with the enclosed air as a single moving mass already? It seems we could almost inject urethane foam into that cavity but Dacron has far less mass.

Thanks for your patience- I'm trying to wrap my brain around all of this. :-(

Last edited:

The edges extend to under the driver mount. The edges of the drivers hold the pillow in place.

dave

dave

So, The fiberglass within this bag has a mass, of course. I assume the attaching edges are slightly compliant? The material of the bag is going to be porous, no doubt.

Can this thing flop around or impede the air volume movement as the woofers move forward and backward of the mounting plate, like a membrane?

Just trying to identify the physics of the device, and do appreciate you sharing your experience.

Thanks

-Charles

p.s. I've got to admit I'm hesitant to add anything that may vibrate, resonate, or act as an air brake.

Can this thing flop around or impede the air volume movement as the woofers move forward and backward of the mounting plate, like a membrane?

Just trying to identify the physics of the device, and do appreciate you sharing your experience.

Thanks

-Charles

p.s. I've got to admit I'm hesitant to add anything that may vibrate, resonate, or act as an air brake.

- Home

- Loudspeakers

- Subwoofers

- Question about compound woofers