I picked up 3 Ashley fet2000 amps a couple years ago and really love their sound quality - and the headroom they provide when driving some Martin Logan SL3's.

I already replaced the fans with DC brushless versions to eliminate the noisy fans. Even added an adjustable AC-DC supply that allows me to dial in the fan speed.

The last thing I would like to do is find a way to minimize the transformer hum that is slightly audible when the room is rather quiet.

This is not a hum that comes through the speakers - but something that you can physically hear come from the chassis.

Is there some sort of isolation fastener that can be purchased that will help minimize the transfer of this vibration/hum into the chassis?

It seems like de-coupling the transformer from the chassis would help isolate some of the noise.

I have been looking around online and also found another thing that may help eliminate this is to re-dip the transformer to help cut back on the vibration of the windings?

The transformers in these things are absolutely massive. As in: as large or larger than the transformers of many small 90 amp wire welders. No joke.

Ideas? Links? Any help appreciated!

-Dean

I already replaced the fans with DC brushless versions to eliminate the noisy fans. Even added an adjustable AC-DC supply that allows me to dial in the fan speed.

The last thing I would like to do is find a way to minimize the transformer hum that is slightly audible when the room is rather quiet.

This is not a hum that comes through the speakers - but something that you can physically hear come from the chassis.

Is there some sort of isolation fastener that can be purchased that will help minimize the transfer of this vibration/hum into the chassis?

It seems like de-coupling the transformer from the chassis would help isolate some of the noise.

I have been looking around online and also found another thing that may help eliminate this is to re-dip the transformer to help cut back on the vibration of the windings?

The transformers in these things are absolutely massive. As in: as large or larger than the transformers of many small 90 amp wire welders. No joke.

Ideas? Links? Any help appreciated!

-Dean

Hello Dean,

as someone who has personally worked with what I am going to suggest, it is not a cheap solution but is engineered for doing, as far as I know, exactly the type of thing you want to do. They are called vibration dampers. EATON makes them, I can't seem to link a page here, but search for "EATON Neoprene mounts". I don't have much experience with Neoprene types as the ones I used were made of thick wire, more like cable, but the principle remains the same. I don't know if EATON, or any other company makes ones small enough to put inside your amplifier, but this is the only thing I can think of now. Interesting issue.

as someone who has personally worked with what I am going to suggest, it is not a cheap solution but is engineered for doing, as far as I know, exactly the type of thing you want to do. They are called vibration dampers. EATON makes them, I can't seem to link a page here, but search for "EATON Neoprene mounts". I don't have much experience with Neoprene types as the ones I used were made of thick wire, more like cable, but the principle remains the same. I don't know if EATON, or any other company makes ones small enough to put inside your amplifier, but this is the only thing I can think of now. Interesting issue.

You can decouple it from the chassis by unscrewing the hardware and physically lifting the transformer to hear any effect. Do all three of them make the same hum?

I have an amp with a transformer that gets noisy by just touching the chassis, but pretty quiet when separated by ~1/4 inch.

I have an amp with a transformer that gets noisy by just touching the chassis, but pretty quiet when separated by ~1/4 inch.

First, dip in varnish, when warm.

There are threads about that here on the forum.

Second, use a thick....4 mm or more pad of whatever gasket like material you have handy. Water jointing gasket sheet, car carpet scrap, bitumen washers and so on

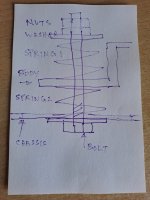

If there is room, and isolation mount can be made by putting two small springs to hold the transformer feet in place, and the supporting bolt held to the chassis. This is for each point, the idea is similar to the engine mounts in cars, where two rubber bits on either side support the central part.

DC brush less fans are simply induction motors with a DC-AC converter circuit inside.

Some fail short circuit, and damage supplies.

Change to a lower delivery (means lower noise) AC fan,... see the fan maker specs.

If there is room, use the fan from a frost free refrigerator...quiet, and huge air delivery.

There are threads about that here on the forum.

Second, use a thick....4 mm or more pad of whatever gasket like material you have handy. Water jointing gasket sheet, car carpet scrap, bitumen washers and so on

If there is room, and isolation mount can be made by putting two small springs to hold the transformer feet in place, and the supporting bolt held to the chassis. This is for each point, the idea is similar to the engine mounts in cars, where two rubber bits on either side support the central part.

DC brush less fans are simply induction motors with a DC-AC converter circuit inside.

Some fail short circuit, and damage supplies.

Change to a lower delivery (means lower noise) AC fan,... see the fan maker specs.

If there is room, use the fan from a frost free refrigerator...quiet, and huge air delivery.

A really interesting topic in my opinion, but unfortunately there is not much to be found on this topic. I'm in the process of installing two large toroidal transformers, decoupled from the housing as much as possible...

Indirectly isolating large spans of inner case metal helps keep noise in and vibrations out.

. I prefer dynamat for this purpose but there are some decent alternatives. Vibration gets in that and amplifies electric humming. Electric droning anything makes me nuts.

Secondly placing or replacing rubber graumets between transformer and chassis is also a good measure. With a rubber consistancy that is not too ridged nor too spongy.

. I prefer dynamat for this purpose but there are some decent alternatives. Vibration gets in that and amplifies electric humming. Electric droning anything makes me nuts.

Secondly placing or replacing rubber graumets between transformer and chassis is also a good measure. With a rubber consistancy that is not too ridged nor too spongy.

If the transformer is really so big and heavy I like the following suggestion so much

In my opinion the springs (IMO they have to be more than 2 though) have to be yielding enough and not too rigid at all, touching laterally the transformer to the side it must slightly swing.

If you had enough space in height I would try even the following feet (the height of which is 40 mm) that I use under all my devices with very good results.

The yielding can be modulate removing 1 or more spring in order to get your goal.

Each foot is for 7,5 Kg. and when possible I use 3 of them instead of 4.

I know they might seem excessive to someone, but they would be for transformers that are described as huge/heavy and I believe they would work very well (even if the transformer and the feet have to be attached in some way).

Alternatively I get good results with Nano Tape

https://www.amazon.com/Removable-Adhesive-Nano-Gel-Tape/dp/B07ZCS1LTP

The thick is 2 mm, but obviously some layers can be put on each other in order to reach your result.

In a DIY project I put 2 transformers (not too big and heavy though) on each other with the tape between them and under the bottom one without any noise/vibrations.

P. S.: I do not like too much neoprene for this use because it is a bit too yielding IMO and with time and weight it becomes thinner.

isolation mount can be made by putting two small springs to hold the transformer feet in place

In my opinion the springs (IMO they have to be more than 2 though) have to be yielding enough and not too rigid at all, touching laterally the transformer to the side it must slightly swing.

If you had enough space in height I would try even the following feet (the height of which is 40 mm) that I use under all my devices with very good results.

The yielding can be modulate removing 1 or more spring in order to get your goal.

Each foot is for 7,5 Kg. and when possible I use 3 of them instead of 4.

I know they might seem excessive to someone, but they would be for transformers that are described as huge/heavy and I believe they would work very well (even if the transformer and the feet have to be attached in some way).

Alternatively I get good results with Nano Tape

https://www.amazon.com/Removable-Adhesive-Nano-Gel-Tape/dp/B07ZCS1LTP

The thick is 2 mm, but obviously some layers can be put on each other in order to reach your result.

In a DIY project I put 2 transformers (not too big and heavy though) on each other with the tape between them and under the bottom one without any noise/vibrations.

P. S.: I do not like too much neoprene for this use because it is a bit too yielding IMO and with time and weight it becomes thinner.

Last edited:

1 long bolt, 2 nuts, 2 springs, 2 big washers.

The bolt holds the mounted foot between two springs, and the top spring is against a washer, and two nuts hold the thing in place, like lock nuts. Head of bolt also has a washer to hold against body.

The foot is thus suspended between the springs.

This is for each of multiple mounting points.

The bolt holds the mounted foot between two springs, and the top spring is against a washer, and two nuts hold the thing in place, like lock nuts. Head of bolt also has a washer to hold against body.

The foot is thus suspended between the springs.

This is for each of multiple mounting points.

As already said I liked your suggestion, even because I like using the springs.

Personally I would use 4 springs instead of only 2 ones just in order to better modulate their compliance (please read the above "yielding" as "compliance" since the translator finally works as expected) since in my view if the transformer is so big and so heavy then only 2 springs have to be rigid enough to hold so much size and so much weight.

I’m personally sure that with 4 springs I would feel much more comfortable, and the transformer too. IMO

Personally I would use 4 springs instead of only 2 ones just in order to better modulate their compliance (please read the above "yielding" as "compliance" since the translator finally works as expected) since in my view if the transformer is so big and so heavy then only 2 springs have to be rigid enough to hold so much size and so much weight.

I’m personally sure that with 4 springs I would feel much more comfortable, and the transformer too. IMO

This time I used a vibration damper as the central attachment point, with M6 internal threads on both sides. But so that the transformer is better supported, I glued a wide absorber foam ring to the underside of the transformer mounting plate.

The vibration damper decouples the fastening screw of the transformer from the housing and the transformer sits vibration-damped on the mounting plate.

The vibration damper decouples the fastening screw of the transformer from the housing and the transformer sits vibration-damped on the mounting plate.

I had a project with a very large transformer. The mistake that many people make is by using vibration absorbing washers, but then bolts that transmit the vibration anyway! In my project, I found 't type' silicone washers followed on top with a regular washer. Of course, the trick then is to only tighten enough to hold everything in place but no more. Unbelievably effective. You might also add soft silicone feet under the chassis to further isolate vibration from its source.

I have used these so far.

https://indifit.co.uk/product/fv10-black-rubber-anti-vibration-mounts-male-male-fitting/

https://indifit.co.uk/product/fv10-black-rubber-anti-vibration-mounts-male-male-fitting/

- Home

- Design & Build

- Construction Tips

- Isolate transformer vibration