UPDATE:

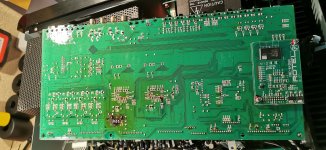

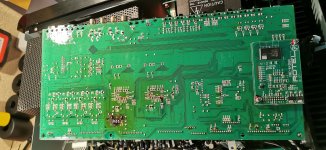

I finally got to opening Rotel last weekend, and this is the underside of the digital PCB.

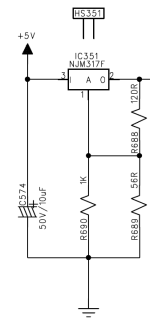

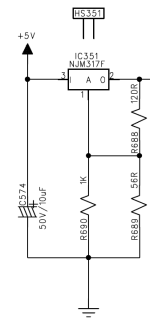

The big smudge is below a voltage regulator (IC351), that runs quite hot (80-90°C) when amp is on. Not sure exactly what it is, might be the glue that @wiseoldtech was talking about, or just charred leftovers of flux.

I've taken out and checked all the boards, and that's the only one with the issue.

So I cleaned it well with IPA, and...

The crackling is GONE!!!

I've been testing it all day today, and so far it looks good. Didn't check with all the inputs as it's not fully assembled yet, but so far I cannot get any weird noises out of it. 👍

So once again, a BIG THANKS to everyone who contributed!! Couldn't have done it without you!

P.S. the biggest issue I currently have is whether to reconnect the old Rotel or to go with the new Onkyo RZ50... 😆

I finally got to opening Rotel last weekend, and this is the underside of the digital PCB.

The big smudge is below a voltage regulator (IC351), that runs quite hot (80-90°C) when amp is on. Not sure exactly what it is, might be the glue that @wiseoldtech was talking about, or just charred leftovers of flux.

I've taken out and checked all the boards, and that's the only one with the issue.

So I cleaned it well with IPA, and...

The crackling is GONE!!!

I've been testing it all day today, and so far it looks good. Didn't check with all the inputs as it's not fully assembled yet, but so far I cannot get any weird noises out of it. 👍

So once again, a BIG THANKS to everyone who contributed!! Couldn't have done it without you!

P.S. the biggest issue I currently have is whether to reconnect the old Rotel or to go with the new Onkyo RZ50... 😆

Update 2:

Not sure whether to laugh 🤣 of cry 😭. It was running for a couple of hours with no crackling, and within 5minutes of posting here, crackling has returned... 🤪😠

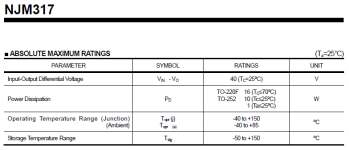

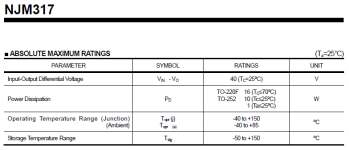

Well, back to the drawing board. Maybe I'll try replacing this hot chip (NJM317F), if I can find it.

Not sure whether to laugh 🤣 of cry 😭. It was running for a couple of hours with no crackling, and within 5minutes of posting here, crackling has returned... 🤪😠

Well, back to the drawing board. Maybe I'll try replacing this hot chip (NJM317F), if I can find it.

Update 3:

Well, now that the Rotel is open, and when it starts crackling, if I spray the abovementioned regulator chip (NJM317F) with the cold spray for electronics, the crackling stops for a few minutes. Maybe there are some other faults, but this one I should deal with first.

Well, now that the Rotel is open, and when it starts crackling, if I spray the abovementioned regulator chip (NJM317F) with the cold spray for electronics, the crackling stops for a few minutes. Maybe there are some other faults, but this one I should deal with first.

The 317 IC's will "shut down" if overheated - they have a built-in temp sensor system.

Probably run near its limits and lacking a proper sized heatsink.

Typical of cheapening and cutbacks of newer products.

And that carbon buildup becomes conductive too.. needs total removal/cleaning.

The foil tracks are compromised too as is the soldering.

Other reasons could be what the IC is powering - and causing too much of a load resulting in the overheating.

Probably run near its limits and lacking a proper sized heatsink.

Typical of cheapening and cutbacks of newer products.

And that carbon buildup becomes conductive too.. needs total removal/cleaning.

The foil tracks are compromised too as is the soldering.

Other reasons could be what the IC is powering - and causing too much of a load resulting in the overheating.

Not sure if it really is overheating, as per technical datasheet junction temp could go to 150°C. And I measure 85-90 on the heatsink.

It regulates 1.8V output, so either that chip is somehow faulty, or -as you said- the DSP's that it provides the 1.8V to are drawing too much power. And I don't have the equipment to check all that.

I believe I've cleaned all the charred carbon buildup...good thing is I don't think that it "burned" through the protective layer, so the tracks below should be OK. It was mostly just on-surface charring.

But what I still don't get, is why then the crackling stops after several minutes.

It regulates 1.8V output, so either that chip is somehow faulty, or -as you said- the DSP's that it provides the 1.8V to are drawing too much power. And I don't have the equipment to check all that.

I believe I've cleaned all the charred carbon buildup...good thing is I don't think that it "burned" through the protective layer, so the tracks below should be OK. It was mostly just on-surface charring.

But what I still don't get, is why then the crackling stops after several minutes.

Last edited:

Heatsink temperature is NOT Junction temp, which can be substantially higher.

This has been discussed ad-nauseum in other threads.

This has been discussed ad-nauseum in other threads.

Never said it was. Just wouldn't expect 60-70°C difference between the two.Heatsink temperature is NOT Junction temp, which can be substantially higher.

This has been discussed ad-nauseum in other threads.

Depending on how the regulator IC is mounted to a heatsink, the difference can be anything.

Dry mounting?, insulator type?, if grease was used, type of grease, metal or plastic IC tab?, heatsink size, etc.

Dry mounting?, insulator type?, if grease was used, type of grease, metal or plastic IC tab?, heatsink size, etc.

This seems to be through hole version. Maybe 50 Cent. So easy to change. NJM317 is out of production, the LM317 is the same part and you can get it at every corner. You did not show the parts side of the PCB, if it does not have a heat sink, consider to fit one. It is soo cheap and easy to change, just do it.

If you are unsure, cut of the plastic part of the NJM317 and then remove each singe leg, simpler than all 3 at a time. Get some "Entlötlitze" with the LM317. Works well for cleaning up. Buy good .8-1mm solder with core, no "lead free". Just good electronics repair stuff, like Stannol. It is still allowed for repair.

Anyway, I would check the unregulated voltage (input of 317), it may be too high for some reason. If a capacitor has gone dry, there may be too much ripple stressing the 317. A simple resistor could take quite some load away from the regulator, but better look for the cause.

If it was not Rotel, I would expect some other part to be the initial cause for overheating.

I don't trust the newer Rotel stuff that much, even in any of the older product's I found brown spots on essential components. They always went for cheap and took cost more serious than long therm reliable. Don't get me wrong, you can get away with running a part at 90% of it's capacity, you just don't get the max. life expectancy out of it and half it compared to 80%. Also you don't have tollerances for unexpected changes around the part. May it be a changing capacitor or dust build up.

If you are unsure, cut of the plastic part of the NJM317 and then remove each singe leg, simpler than all 3 at a time. Get some "Entlötlitze" with the LM317. Works well for cleaning up. Buy good .8-1mm solder with core, no "lead free". Just good electronics repair stuff, like Stannol. It is still allowed for repair.

Anyway, I would check the unregulated voltage (input of 317), it may be too high for some reason. If a capacitor has gone dry, there may be too much ripple stressing the 317. A simple resistor could take quite some load away from the regulator, but better look for the cause.

If it was not Rotel, I would expect some other part to be the initial cause for overheating.

I don't trust the newer Rotel stuff that much, even in any of the older product's I found brown spots on essential components. They always went for cheap and took cost more serious than long therm reliable. Don't get me wrong, you can get away with running a part at 90% of it's capacity, you just don't get the max. life expectancy out of it and half it compared to 80%. Also you don't have tollerances for unexpected changes around the part. May it be a changing capacitor or dust build up.

Yeah, Turbo, I agree.

Rotel USED to make some really nice reliable stuff.

But the new crap that came into my repair shop isn't in the scame league.

Shame, a lot of 'name brands' that made nice equipment... all went down the drain with the rest of the turds.

That's why I'll stick to my 'vintage' equipment, which is still going strong.

Rotel USED to make some really nice reliable stuff.

But the new crap that came into my repair shop isn't in the scame league.

Shame, a lot of 'name brands' that made nice equipment... all went down the drain with the rest of the turds.

That's why I'll stick to my 'vintage' equipment, which is still going strong.

The documentation I have mentions NJM317, but the chip is clearly LM317.

I will be ordering and replacing it soon enough, but recently I've had some new development which makes no sense at all.

Since the top cover is out of the way, I've been doing some more testing.

Just for info- the topmost card in the box is the HDMI card, below is the digital card (with digital I/O and DSPs, and hot LM), below is analog card and so on.

Currently the HDMI card is physically out, and I cannot reproduce crackling any more. Rotel's been on for almost 2 hours and still nothing.

(yesterday I even tried covering the LM317 with a small ceramic espresso cup to reduce the air flow and keep it even hotter, but without the HDMI card installed there is simply no way to get any crackling out of this unit).

Also one DSP is running a bit hotter then the other (53 vs 45°C, measured by infra thermometer), but the hotter one is closer to LM so it might not mean anything.

But when I install the HDMI card (screw it in (one of the brackets is in front of the LM chip in the picture) and connect all the wires on it) I can get crackling again.

If I then spray it with cold spray, it goes away for a few minutes and then comes back.

Oh and I've checked the input voltage on the LM (have only multimeter, not oscilloscope) and seems OK (in 5.01V, out 1.8V, adj 0.55V-not sure what this one should be).

I am so very confused why there's no crackling when HDMI card is out. 😕

I will be ordering and replacing it soon enough, but recently I've had some new development which makes no sense at all.

Since the top cover is out of the way, I've been doing some more testing.

Just for info- the topmost card in the box is the HDMI card, below is the digital card (with digital I/O and DSPs, and hot LM), below is analog card and so on.

Currently the HDMI card is physically out, and I cannot reproduce crackling any more. Rotel's been on for almost 2 hours and still nothing.

(yesterday I even tried covering the LM317 with a small ceramic espresso cup to reduce the air flow and keep it even hotter, but without the HDMI card installed there is simply no way to get any crackling out of this unit).

Also one DSP is running a bit hotter then the other (53 vs 45°C, measured by infra thermometer), but the hotter one is closer to LM so it might not mean anything.

But when I install the HDMI card (screw it in (one of the brackets is in front of the LM chip in the picture) and connect all the wires on it) I can get crackling again.

If I then spray it with cold spray, it goes away for a few minutes and then comes back.

Oh and I've checked the input voltage on the LM (have only multimeter, not oscilloscope) and seems OK (in 5.01V, out 1.8V, adj 0.55V-not sure what this one should be).

I am so very confused why there's no crackling when HDMI card is out. 😕

It's been a common and known problem that those HDMI cards, used in many recent brands of amplifiers, have been a failure problem.

China put out a batch of them that flooded repair shops like mine with HDMI issues.

And trying to get replacements was difficult back in the mid 2000's, likely worse today.

Bottom line, I'd junk anything made between 2000 and 2010, that era delivered too many trouble-prone products.

China put out a batch of them that flooded repair shops like mine with HDMI issues.

And trying to get replacements was difficult back in the mid 2000's, likely worse today.

Bottom line, I'd junk anything made between 2000 and 2010, that era delivered too many trouble-prone products.

Yep, I've just rechecked; I installed HDMI card (without even connecting any of the wires!), turned the box on, after cca 30mins the crackling started. Then I immediately removed it, and the crackling just stopped. So it cannot be due to it as it's not even connected.

Hopefully new LM will arrive in couple of days so I'll see if then the issues will remain the same.

Hopefully new LM will arrive in couple of days so I'll see if then the issues will remain the same.

@doubleDD "Yep, I've just rechecked; I installed HDMI card (without even connecting any of the wires!), turned the box on, after cca 30mins the crackling started. Then I immediately removed it, and the crackling just stopped. So it cannot be due to it as it's not even connected."

That statement is confusing and doesn't make sense, sorry.

That statement is confusing and doesn't make sense, sorry.

So let me rephrase it:

The (over)heating IC chip LM317 is on the digital board, which is just below the HDMI board in the device. Since the crackling only exists when both boards are installed (see post #31), I initially thought that maybe the error is on the HDMI board, and not on the digital one. But, in my last test, I discovered that crackling also appears if the HDMI board is just installed but not connected (none of the wires/connectors), so the error can't be on it- since it's not connected, there's no signals going through it. And the crackling stops as soon as I remove the HDMI board. So it would seem (to me) that the problem is on the digital board, and that the HDMI board just reflects the heat back to the digital one.

I tried to replicate that behaviour by using ceramic cup (as described before), but apparently it doesn't cover enough area so it doesn't heat up the same elements (that are heated by reflection from the HDMI board). Maybe I should also consider replacing some of the electrolytic caps around the LM, maybe they are damaged by the heat, but I don't know how to test them.

The (over)heating IC chip LM317 is on the digital board, which is just below the HDMI board in the device. Since the crackling only exists when both boards are installed (see post #31), I initially thought that maybe the error is on the HDMI board, and not on the digital one. But, in my last test, I discovered that crackling also appears if the HDMI board is just installed but not connected (none of the wires/connectors), so the error can't be on it- since it's not connected, there's no signals going through it. And the crackling stops as soon as I remove the HDMI board. So it would seem (to me) that the problem is on the digital board, and that the HDMI board just reflects the heat back to the digital one.

I tried to replicate that behaviour by using ceramic cup (as described before), but apparently it doesn't cover enough area so it doesn't heat up the same elements (that are heated by reflection from the HDMI board). Maybe I should also consider replacing some of the electrolytic caps around the LM, maybe they are damaged by the heat, but I don't know how to test them.

Just replace the LM317 and see. Do not make any experiments heating the LM even more. If it fails and the 1.8Volt processors get 5V your AVR is done.

The 10uF cap is the next to replace. If you have no osciloscope you are repairing with one hand tied behind your back.

The 10uF cap is the next to replace. If you have no osciloscope you are repairing with one hand tied behind your back.

Even if you have got an osciloscope, you may not find the fault. Repairing such stuff is a profession you have to learn and because new things keep comming, you never stop learning. You need a lot of experience, logical thinking and patience to repair such over complicated machines like an AVR.

If you really want to keep the Rotel, think about stopping after replacing the cap and regulator. Maybe get a used or even new osciloscope and start again after having learned some basics about it. The worst thing that can happen is that you loose a few Frankli selling the osciloscope.

If you really want to keep the Rotel, think about stopping after replacing the cap and regulator. Maybe get a used or even new osciloscope and start again after having learned some basics about it. The worst thing that can happen is that you loose a few Frankli selling the osciloscope.

I still don't have any news regarding the repair, but I have one (possibly silly) question - can I use Rotel as an end stage/power amp? For instance, if I connect front (and possibly center) speakers from my new AVR pre-out terminals to Rotel multi input, and set Rotel to bypass(direct) mode and the volume to fixed? Would that work or is it a recipe for some internal disaster? Would I be able to change the volume of the front (and center) speakers on the AVR unit then?

Thanks!

Thanks!

That's a mouthful!Even if you have got an osciloscope, you may not find the fault. Repairing such stuff is a profession you have to learn and because new things keep comming, you never stop learning. You need a lot of experience, logical thinking and patience to repair such over complicated machines like an AVR.

Suggesting expensive/complex servicing tools is pretty rediculous if the person doesn't have the BASIC and some ADVANCED training in how to operate the equipment in the first place.Maybe get a used or even new osciloscope and start again after having learned some basics about it. The worst thing that can happen is that you loose a few Frankli selling the osciloscope.

That's like asking a blind 5 year old to fly an airplane.

Suggesting expensive/complex servicing tools is pretty rediculous if the person doesn't have the BASIC and some ADVANCED training in how to operate the equipment in the first place.

That's like asking a blind 5 year old to fly an airplane.

Frankly, so is the comment that if someone doesn't have the tools, that they don't know how to use them.

This "blind kid" has 10years of education in electrical engineering and was quite handy with all the instruments, including the oscilloscope, while he had the need to use them.

Tone down the american sass, this is diyaudio, not freedom forum. Thanks.

- Home

- Amplifiers

- Class D

- Weird crack(l)ing sounds coming from my Rotel RSX-1562