Hi guys,

I salvage all the cheap faulty home theater amps I can find as they are a great source of power transformers and heatsinks etc.

I have not once seen a soft start system (at least that I am smart enough to recognize).

Some of these amps have 600 or 700w power transformers.

Conventional wisdom of the internet states that anything over roughly 300VA should have a soft start. This is if course stated to toroidal types however my understanding is that regular EI types are not much better.

Am I missing something?

I salvage all the cheap faulty home theater amps I can find as they are a great source of power transformers and heatsinks etc.

I have not once seen a soft start system (at least that I am smart enough to recognize).

Some of these amps have 600 or 700w power transformers.

Conventional wisdom of the internet states that anything over roughly 300VA should have a soft start. This is if course stated to toroidal types however my understanding is that regular EI types are not much better.

Am I missing something?

Maybe it's cheaper to overspec the bridge rectifier than put in a soft-start circuit? They do make a bit of a clunk sometimes for sure.

Most consumer grade use EI transformers that suffer less from in rush currents compared to toroids.

On good quality products above say 70-100W per channel, most will have some form of in-rush limiting and especially if using a toroid

On good quality products above say 70-100W per channel, most will have some form of in-rush limiting and especially if using a toroid

Without the soft start you get a nice HUMMM!!! and dimming of the room lights when you power up the amplifier. Maybe that gives people the illusion that it's a really powerful amp. Good for marketing. Not so good for reliability, but hey... That expensive transformer will take 20 years to wear out so it won't be covered by the warranty.

Tom

Tom

My impression is that many have a simple PTC inrush limiters, which is probably "good enough" for most cases - and much cheaper. If it is "mass-market" products you'll be surprised how much focus there is on BoM-cost savings.

Also, most HT receivers are not filled to the brim with VA and uF like a DIY-amp, but spec'ed closer to the theoretical power requirements. That means even a mid-range receiver probably doesn't really need a dedicated soft-start circuit.

Also, most HT receivers are not filled to the brim with VA and uF like a DIY-amp, but spec'ed closer to the theoretical power requirements. That means even a mid-range receiver probably doesn't really need a dedicated soft-start circuit.

This an example of a very simple but yet efficient and cheap solution. 5R/10W resistor, heavy duty relay, as implemented in series I Bose 1800/1801 (2 KVA transformer, EI or double C, depending on manufacturing date).

Never had the slightest problem with it. Can probably be done in any power amp.

Never had the slightest problem with it. Can probably be done in any power amp.

Cello used the switched out resistor approach in their larger power amps. Also used those inrush current limiter thingies (can't remember what they're called) in their preamps.

The Bose 1800 v5 was a rebadged MC2 Audio T series amp (I do not know if that is the version you are referring to).This an example of a very simple but yet efficient and cheap solution. 5R/10W resistor, heavy duty relay, as implemented in series I Bose 1800/1801 (2 KVA transformer, EI or double C, depending on manufacturing date).

Never had the slightest problem with it. Can probably be done in any power amp.

View attachment 1153065

You can still buy those but the external design has changed a little bit. Others who use(d) rebadged MC2 Audio amps are Dynaudio Acoustics, Funktion One, Turbosound, Tannoy and Quested.

Although they used MC series amps which had a very much more sophisticated 'soft start'.

Yeah, for low power devices the PTC (Positive Temperature Coefficient) is largely used. Examples https://eepower.com/resistor-guide/resistor-types/ptc-thermistor/#

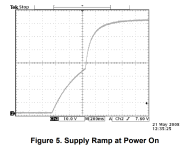

Texas Instruments application note AN-1849 shows a simple soft start circuit. The softener is eliminated ("bypassed") after the DC supply has risen above X percent of its final asymptotic value. You can see that dV/dt increases noticeably.

_

_

Attachments

I was referring to series I, the real Bose design.The Bose 1800 v5 was a rebadged MC2 Audio T series amp (I do not know if that is the version you are referring to).

You can still buy those but the external design has changed a little bit. Others who use(d) rebadged MC2 Audio amps are Dynaudio Acoustics, Funktion One, Turbosound, Tannoy and Quested.

Although they used MC series amps which had a very much more sophisticated 'soft start'.

Bose 1800 series V (and VI) is in fact a re-badged and modified Carver amplifier, as I discovered when repairing a couple of them : https://goo.gl/photos/z8fmNPMs1mABsdHSA

I wrote a complete story of the Bose 1800, from series I to series VI. Many manufacturers were contracted by Bose to build these amps (Daub, Stage Accompany, Carver) apart from series I which was a genuine Bose design. I talked with a retired Bose engineer who worked on this product back in the late seventies.

Quite understandable, Bose marketed so many outsourced amps that it's easy to be confused. This is off topic, but they even made this, a Carver amplifier built (like a tank) around a Phoenix Gold module !!! https://photos.app.goo.gl/SY8IApryoGAlAtYU2My mistake.

Wouldn't you want NTC for inrush limitation?Yeah, for low power devices the PTC (Positive Temperature Coefficient) is largely used. Examples https://eepower.com/resistor-guide/resistor-types/ptc-thermistor/#

PTC are used in air conditioners as well, for starting every cooling cycle in an on-off type control.

The new inverter machines, with BLDC motors, do not need that, they are controlled by drives.

PTC will go high, so how will you feed the amp?

I think you need NTC, and maybe a timer / ramp on the volume control if you need to control start up hum.

The new inverter machines, with BLDC motors, do not need that, they are controlled by drives.

PTC will go high, so how will you feed the amp?

I think you need NTC, and maybe a timer / ramp on the volume control if you need to control start up hum.

PTC's are used in CRT degaussing of color television sets and crt pc monitors, they also limit current, but is quite useless in audio amps...

Yes of course, sorry for mistyping.Wouldn't you want NTC for inrush limitation?

Some good answers, why not is probably a cost vs a need issue. Certainly helps with surges on the switches

One issue to address is how the soft-start ckt behaves under a fault condition. This is and should be a safety or regulatory requirement.

I use a similar technique as shown in post #6 but borrow from pioneer designs like sx-1280,1980 where they use a thermal fuse under and in contact with the big resistor. If the relay does not close shorting out the big resistor it will get hot and open the thermal fuse rather than having a melt down situation of the big power resistor.

One issue to address is how the soft-start ckt behaves under a fault condition. This is and should be a safety or regulatory requirement.

I use a similar technique as shown in post #6 but borrow from pioneer designs like sx-1280,1980 where they use a thermal fuse under and in contact with the big resistor. If the relay does not close shorting out the big resistor it will get hot and open the thermal fuse rather than having a melt down situation of the big power resistor.

Last edited:

If you use power resistors for inrush limiting, beware that instantaneous power dissipated in the resistor on start-up is often very substantial. As in several kW. If you want the inrush limiter to last you need to choose a resistor that can handle this kind of peak power ... or go with an NTC designed for the purpose and short that out with a relay.This an example of a very simple but yet efficient and cheap solution. 5R/10W resistor, heavy duty relay, as implemented in series I Bose 1800/1801 (2 KVA transformer, EI or double C, depending on manufacturing date).

One advantage of the NTC over the power resistor (in addition to better reliability) is that the NTC will heat up from the inrush current, which results in a gradual lowering of the resistance throughout the inrush event. This, in turn, results in faster startup and thereby a smaller second inrush event when the NTC is bypassed by the relay.

If you're interested in the various tradeoffs of soft start design, I suggest having a look at my guide on the topic. I show quite a few measurements of the inrush current as well: The Ultimate Guide to Soft Start Design | Neurochrome.

Tom

- Home

- Amplifiers

- Power Supplies

- Why dont commercial manufacturers use soft starts?