This could be one to try i suspect not cheap

https://www.calderlead.co.uk/healthcare/lead-lined-boards

https://www.calderlead.co.uk/healthcare/lead-lined-boards

hi thank you for the interesting hintThis could be one to try i suspect not cheap

https://www.calderlead.co.uk/healthcare/lead-lined-boards

To get dampening and stiffness the version with steel sheet should be perfect

but i have seen a video of a speaker with a stiff metal cabinet They say that it can actually ring but the resonances are very easy to dampen with normal sheets

The problem is to work on metal

Steel is unbelievably stiff

The Leema Acoustics Xen had steel used in it's construction, it would be interesting to know how thick it is. I would presume that thin (ie 1 1/16 inch) steel with the odd brace) would work on a small cabinet, and be well damped by 1/8 thick mat sold in car accessory stores. Perhaps a rubbery mat sandwiched between two 1/16th inch steel sheets would be well damped, reasonably stiff, but a bugger to join.

https://images.app.goo.gl/uYBRN8BdYytSNhAS8The Leema Acoustics Xen had steel used in it's construction, it would be interesting to know how thick it is. I would presume that thin (ie 1 1/16 inch) steel with the odd brace) would work on a small cabinet, and be well damped by 1/8 thick mat sold in car accessory stores. Perhaps a rubbery mat sandwiched between two 1/16th inch steel sheets would be well damped, reasonably stiff, but a bugger to join.

there is no doubt about steel stiffness being much superior to any other common material

about 20 times the wood

so that jus 1mm of steel has the same stiffness of 20mm of wood? am I right?

but i would rather think to a metal frame supporting the drivers

the panels could be attached with magnets to the frame

they will have just to seal the box in the end

Last edited:

I've started building cabinets with solid aluminium extrusions. First up is a 11 litre cabinet with a U channel for the front and part of the sides. The U channel is 152mm wide and 380mm tall and around 8mm thick. The sides are 76mm width each. See here:

https://www.aluminium-online.co.uk/product/6-x-3-x-1-4-x-3-8-aluminium-channel/

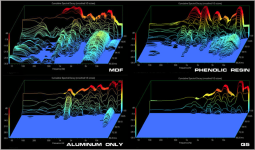

For drivers and crossover I used the innards of a Wharfedale Programme 30D-6, 135mm (=150mm) midbass and 1" tweeter. The thing is when I compared the originals on the left to the new alu cabinets on the right, the new cabs were quite a bit quieter. Can I put this down to the inert nature of the aluminium in the new cabs? The original cabs are 5.5 litres, 9mm MDF undamped and I'm assuming that some volume is coming through the cabinet walls. I attach a Magico graph of spectral decay, the last Q5 being for their own cabinets with added damping. This also shows big differences in cabinet material

I'm trying to understand this loss of volume, but nobody here seems to build with aluminium cabinets so not getting any real feedback. Loss of volume would affect the crossover for starters.

Attached pics of provisional new cabinets (sealed), original Wharfedales (ported) and Magico graph. I'm assuming that sealed versus ported would decrease some volume low down, but the loss is in the mids mostly. You can hear the coloration of the original cabinets.

https://www.aluminium-online.co.uk/product/6-x-3-x-1-4-x-3-8-aluminium-channel/

For drivers and crossover I used the innards of a Wharfedale Programme 30D-6, 135mm (=150mm) midbass and 1" tweeter. The thing is when I compared the originals on the left to the new alu cabinets on the right, the new cabs were quite a bit quieter. Can I put this down to the inert nature of the aluminium in the new cabs? The original cabs are 5.5 litres, 9mm MDF undamped and I'm assuming that some volume is coming through the cabinet walls. I attach a Magico graph of spectral decay, the last Q5 being for their own cabinets with added damping. This also shows big differences in cabinet material

I'm trying to understand this loss of volume, but nobody here seems to build with aluminium cabinets so not getting any real feedback. Loss of volume would affect the crossover for starters.

Attached pics of provisional new cabinets (sealed), original Wharfedales (ported) and Magico graph. I'm assuming that sealed versus ported would decrease some volume low down, but the loss is in the mids mostly. You can hear the coloration of the original cabinets.

Last edited:

In the July 2008 issue of Hi-Fi World, Peter Comeau discussed, in an article on the WD25TV2 speaker, cabinet materials. He showed spectrograms of various materials and came to the conclusion that something he called 'Arcena' was the best choice. It turns out Arcena is simple to DIY: 18mm of chipboard (used to be called particle board, or K3 in Canada) bonded to an outer layer of MDF, veneered. The pulpy core of the chipboard works in consort with the denser layer of MDF. Chipboard is far less common than it once was, but I found a couple places that still carry it.

No. 1mm steel sheet is wobbly, 20mm wood is fine.https://images.app.goo.gl/uYBRN8BdYytSNhAS8

there is no doubt about steel stiffness being much superior to any other common material

about 20 times the wood

so that jus 1mm of steel has the same stiffness of 20mm of wood? am I right?

You always have to take the weight of the material into account! Take a sheet of metal and wood with THE SAME WEIGHT - you get totally different thickness and different stiffness!

There are 2 factors - the Berger's mass law. Material dampenes the sound through - mass. The heavier the better. But you need to transport the speaker, no use for a 1000kg cabinet.

Coincidence frequency. Depends on density, elastic modulus and thickness of the material. You get a pretty bad notch in the damping behaviour over frequency.

Actually wood is pretty good - when you get in the area of 40-50mm thickness!

9mm MDF undampened ... that's really bad. But glue 3-4 of them together with elastic glue ... that's hard to beat!

Regarding Arcena, as I recall, my friend Greg, who was peripherally involved with World Designs, told me that the actual reason was that although Peter favoured chipboard / particleboard for cabinet construction (and probably still does), dealing with the ragged edges in the construction for aesthetics & to ensure a proper air-seal would have been too much of a pain for the WD speakers he was producing at the time. The chipboard laminated with oak-veneered MDF was the compromise solution he / WD came up with and named Arcena, so it could be used as a marketing feature.

Stacks of thin material with damping in between keeps the coincidence frequency high -> good. For wood that's thickness of about 7-9mm, depending on wood type.

So if you stack MDF/Plywood/... with greenglue or elastic wood floor glue - you should get great results.

So if you stack MDF/Plywood/... with greenglue or elastic wood floor glue - you should get great results.

Hi ! thank you very much for the very interesting post I am very ignorant but i have the feeling that this is the kind of graph that says a lot indeedI've started building cabinets with solid aluminium extrusions. ... and Magico graph. I'm assuming that sealed versus ported would decrease some volume low down, but the loss is in the mids mostly. You can hear the coloration of the original cabinets.

View attachment 1180589

The Q5 i really impressive ... maybe the FR is not the best but the response to impulse looks astonishing ... no ringing at any freq Very impressive indeed

Another thing ... i have the impression that the ringing of the aluminum cabinet can be tamed very easily with some viscoelastic material placed in the center of the cabinet's panels Lead would be the absolute best

Of course also the ringing of the drivers counts But the cabinet will not add any other ringing Pure sound

Stacks of thin material with damping in between keeps the coincidence frequency high -> good

Description of Plywood. More layers = plies is usually better.

dave

"...i have the impression that the ringing of the aluminum cabinet can be tamed very easily with some viscoelastic material placed in the center of the cabinet's panels..."

Indeed. See this video from Piega - it shows exactly that. The original damping they used was Idikell which was bitumen. Now they use Dinaphon which looks to be similar to MLV.

Cabinets from 3.30

https://keller-laermschutz.ch/produkte/dinaphon-m-6001/

https://keller-laermschutz.ch/produkte/idikell-m-4021/

I bought some of this to use: Dodomat DEDN Pro which is heavy butyl

https://www.dodomat.com/products/dodo-dead-mat-pro-black

Indeed. See this video from Piega - it shows exactly that. The original damping they used was Idikell which was bitumen. Now they use Dinaphon which looks to be similar to MLV.

https://keller-laermschutz.ch/produkte/dinaphon-m-6001/

https://keller-laermschutz.ch/produkte/idikell-m-4021/

I bought some of this to use: Dodomat DEDN Pro which is heavy butyl

https://www.dodomat.com/products/dodo-dead-mat-pro-black

Plywood uses wood glue to bond the layers - this is a hard conection and doesn't have damping properties. So it acts more or less like other wood materials, differences are relatively small. But Plywood was still the best wood material in my tests, no unwanted side effects (like chipboard can show).Description of Plywood. More layers = plies is usually better.

Earl Geddes used to use melamine glue for CLD, which seems to be based on PVA. Reports suggest it works, maybe not the first product one would choose but similar to green glue which is used for the same purpose.

Plywood uses wood glue to bond the layers - this is a hard conection and doesn't have damping properties

But the transition from one ply thru teh glue to the next ply orientated at 90° provides damping. You can take advantage of it.

dave

No - not really. You don't get emphased resonances as you can get with solid wood but the glue is harder as the wood - that's not damping. Do some tests and compare to MDF - not a big difference.

Those Dodge's are unobtanium even on this side of the pond.Especially when pulled over the ears (I find my faux version has that effect)...

Joking aside, probably. Although as has been alluded to, lower isn't necessarily better. Can be for midrange & HF chambers. Bass boxes? I'd rather shunt panel resonances above their operating band. I like heavy-metal engineering as much as the next person (the old long-ram V8s are one of my side-interests, albeit a tricky one from this side of the Atlantic) but it's not the most efficient when it comes to acoustics.

Certainly for any price mere mortals like ourselves could ever afford.  It'd probably be cheaper to build an entire engine with custom-built block, head & whatever other components can't be found in reproduction. Which is probably about 85% of the whole damn thing, and not exactly going to come into the definition of 'cheap'. 😉 I still find them interesting -some those engineers were insanely creative.

It'd probably be cheaper to build an entire engine with custom-built block, head & whatever other components can't be found in reproduction. Which is probably about 85% of the whole damn thing, and not exactly going to come into the definition of 'cheap'. 😉 I still find them interesting -some those engineers were insanely creative.

It'd probably be cheaper to build an entire engine with custom-built block, head & whatever other components can't be found in reproduction. Which is probably about 85% of the whole damn thing, and not exactly going to come into the definition of 'cheap'. 😉 I still find them interesting -some those engineers were insanely creative.

It'd probably be cheaper to build an entire engine with custom-built block, head & whatever other components can't be found in reproduction. Which is probably about 85% of the whole damn thing, and not exactly going to come into the definition of 'cheap'. 😉 I still find them interesting -some those engineers were insanely creative.- Home

- Loudspeakers

- Full Range

- Cabinet material Measurement