At that rate, likely the motor/pulley.I have a Thorens TD-160 but never experienced the 3 Hz rumble. Wouldn't be better to eliminate the source of the rumble? Cleaning the bearing and spindle, replacing the belt, checking the motor phase shifting capacitor, etc. What is rotating at 3/s, 180/minute?

Woofer pumping is most likely caused by warps in the LP. Even very small warps can cause it. When the stylus reaches the top of the warp the cartridge overshoots causing the stylus to drop WRT the cartridge then as the stylus goes down and reaches the bottom the cartridge compresses the stylus. This causes the cartridge to output a signal that causes woofer pumping. A tonearm with a low COG can make the situation worse by bouncing the cartridge.Please let me be clear that it was not rumble what I had, and as I said I saw it happened also on another Thorens, with a different arm and a different preamp. Frequency is very low, because you can actually see the woofer moving slowly. But I was expecting to find someone here that did have a belt drive tt.

The only way to reduce it is to install a low compliance cartridge, a lower inertia tonearm or add viscous damping.

Once the low frequency signal is there the fundamental can be removed but it's impossible to remove its effect, as it will already have modulated every single note.

As warrjon mentioned, the woofer pumping is often due to a warp in the record, the stylus swaying from it, and thus the sub sonic signal is amplified by the system.

Amplifiers with the ability to send this unhearable noise to the speakers and also cause the actual music to modulate.

And as I previously stated, this needs to be corrected.

There is no need for any amplifier to reach down to below 20Hz anyway.

I suggested using a subsonic filter, which seems to be rejected or ignored.

Amplifiers with the ability to send this unhearable noise to the speakers and also cause the actual music to modulate.

And as I previously stated, this needs to be corrected.

There is no need for any amplifier to reach down to below 20Hz anyway.

I suggested using a subsonic filter, which seems to be rejected or ignored.

OK, I will spend this Saturday morning recording my Thorens TD145 MkII with Hanze hifi tuned motor. Belt is rather new and main bearing has new oil. Just a minute!

Last edited:

Some mesurements and ramblings of my Thorens TD145 Mk II

I have a 30+ years old second hand belt drive TT with a tuned motor and custom case and feet. The cartridge used is AKG P8ES. TD145 is close relative to TD160 that the OP has. Major differences are plate and casing. Mk2 versions have lighter carbon tonearm.

https://www.theanalogdept.com/thorens_history.htm

I have a Terratec iVinyl ADC (no longer available) that I have used for digitizing my records and to test TTs and cartridges. It has selectable capacitance and gain and works also as direct line level ADC. It doesn't have any highpass filtering, which is a nice feature for these tests. For recording I use Audacity set to floating point 32bit.

When I set the TT rotating free as warmup, I noticed (again) that the motor gives clicking noise at each rotation. I used a stethoscope and my fingers to verify that it is the motor's pulley axle clicking, obviously because of wearing. I recorded that noise with UMIK-1, but waveform is difficult to read. Fortunately clicking is not transferred to the TT flywheel and cartridge.

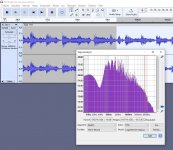

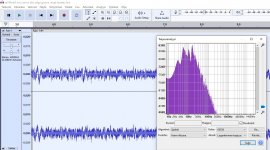

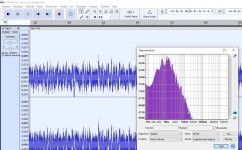

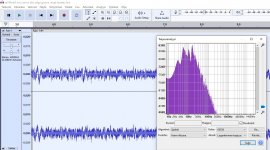

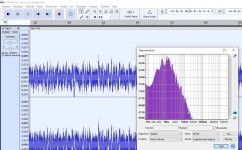

With Audacity we must do something to "see" these very low frequencies - paint long enough time of sample and use high sample count!

As conclusion we can see that my TT's major noise comes from TT body and cartridge resonances at 6/12/32Hz. Room walls, air conditioning and etc. ambient noise are perhaps also conducted.

So, regarding the 3Hz noise that OP has, I suspect that it comes as mechanically conducted resonance from room/house. A highpass filter is needed to prevent extra modulation and woofer stress. This conclusion doesn't come only from this simple litte test session, but is based on my previous tests of three different players and 4 cartridges and tuning tricks to minimize resonant noise.

I have a 30+ years old second hand belt drive TT with a tuned motor and custom case and feet. The cartridge used is AKG P8ES. TD145 is close relative to TD160 that the OP has. Major differences are plate and casing. Mk2 versions have lighter carbon tonearm.

https://www.theanalogdept.com/thorens_history.htm

I have a Terratec iVinyl ADC (no longer available) that I have used for digitizing my records and to test TTs and cartridges. It has selectable capacitance and gain and works also as direct line level ADC. It doesn't have any highpass filtering, which is a nice feature for these tests. For recording I use Audacity set to floating point 32bit.

When I set the TT rotating free as warmup, I noticed (again) that the motor gives clicking noise at each rotation. I used a stethoscope and my fingers to verify that it is the motor's pulley axle clicking, obviously because of wearing. I recorded that noise with UMIK-1, but waveform is difficult to read. Fortunately clicking is not transferred to the TT flywheel and cartridge.

With Audacity we must do something to "see" these very low frequencies - paint long enough time of sample and use high sample count!

As conclusion we can see that my TT's major noise comes from TT body and cartridge resonances at 6/12/32Hz. Room walls, air conditioning and etc. ambient noise are perhaps also conducted.

So, regarding the 3Hz noise that OP has, I suspect that it comes as mechanically conducted resonance from room/house. A highpass filter is needed to prevent extra modulation and woofer stress. This conclusion doesn't come only from this simple litte test session, but is based on my previous tests of three different players and 4 cartridges and tuning tricks to minimize resonant noise.

Last edited:

Fixing the motor clicking https://www.ebay.com/itm/253683167689

But as you can see above, clicking is not transferred to the cartridge signal, at least not in my case. I play vinyl ever three years in average... thanks to Tidal!

https://tidal.com/browse/album/20518501

But as you can see above, clicking is not transferred to the cartridge signal, at least not in my case. I play vinyl ever three years in average... thanks to Tidal!

https://tidal.com/browse/album/20518501

Last edited:

I've been following this thread, I went to Rod's website and purchased the filter PCB, one of the few times I will pay more for shipping than the item.I suggested using a subsonic filter, which seems to be rejected or ignored.

Thank you for sharing this.

For those of us who have built our own phono stages, has anyone had success reducing the value of coupling cap from input stage to 2nd stage to introduce a sort of 'rumble filter'?

I believe I have 0.1uF series cap and 1M ohm shunt resistor (to 0V signal ground). That gives F3 of 1.59Hz. Changing the value of that cap to 0.022uF would move the F3 up to 7.23Hz. Would that attenuate 1 to 3 Hz enough to reduce woofer pumping? Or would that be too shallow of a roll-off to be effective?

I believe I have 0.1uF series cap and 1M ohm shunt resistor (to 0V signal ground). That gives F3 of 1.59Hz. Changing the value of that cap to 0.022uF would move the F3 up to 7.23Hz. Would that attenuate 1 to 3 Hz enough to reduce woofer pumping? Or would that be too shallow of a roll-off to be effective?

You're wasting your time with that consideration, sorry.For those of us who have built our own phono stages, has anyone had success reducing the value of coupling cap from input stage to 2nd stage to introduce a sort of 'rumble filter'?

I believe I have 0.1uF series cap and 1M ohm shunt resistor (to 0V signal ground). That gives F3 of 1.59Hz. Changing the value of that cap to 0.022uF would move the F3 up to 7.23Hz. Would that attenuate 1 to 3 Hz enough to reduce woofer pumping? Or would that be too shallow of a roll-off to be effective?

Your "woofer pumping" isn't going to dissapear with that ineffective approach.

You simply don't understand what is needed, what is effective.

You're quite welcome!I've been following this thread, I went to Rod's website and purchased the filter PCB, one of the few times I will pay more for shipping than the item.

Thank you for sharing this.

I've built several of those to add after phono stages, and they perform exactly as Rod says.

They also improve CD playing that contains sub-sonic power-robbing junk from some CD's.

And.... they're pure analog too.

Well yes, that's the point of asking a question, right? To hopefully gain understanding from others who have that understanding.You're wasting your time with that consideration, sorry.

Your "woofer pumping" isn't going to dissapear with that ineffective approach.

You simply don't understand what is needed, what is effective.

What am I missing?

- Steepness of filter slope?

- Is this a defect of the tonearm/cartridge resonance and adding a rumble filter is a 'band-aid' approach to cover up that defect? In other words, fix the tonearm/cartridge resonance issue first?

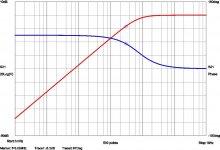

You are correct that changing the cap to 22n will move the -3dB corner frequency to 7.2Hz, but it is a single pole filter (1 reactive element) so it will have a slope of -6dB/octave (see attached .jpeg). The attenuation at 3Hz will only be -8dB and -17dB at 1Hz. It will have some impact, but it may not be enough.Well yes, that's the point of asking a question, right? To hopefully gain understanding from others who have that understanding.

What am I missing?

- Steepness of filter slope?

- Is this a defect of the tonearm/cartridge resonance and adding a rumble filter is a 'band-aid' approach to cover up that defect? In other words, fix the tonearm/cartridge resonance issue first?

If your woofers are pumping faster than once per second, it probably will not be enough. A lot of times, the subsonic woofer pumping will be at the arm/cart resonant frequency which is usually around 10Hz. A lower frequency disturbance will excite the cartridge which will then oscillate at the arm/cart resonant frequency. Increasing the -3dB cutoff frequency above 10Hz will start to attenuate audio frequencies which is undesirable. As WOT posted, a higher order filter will be more effective in both attenuating the undesired rumble and not attenuating the audio frequencies.

Rod's filter is a 6 pole HPF filter which will give a response of -36dB/octave, but it is two 3 pole filters in series which does not have an optimal response at the transition (corner frequency). A properly constructed 6 pole filter would reduce the attenuation of audio frequencies and provide better attenuation of subsonic frequencies, but it appears to do an adequate job.

I posted a DIY 8 pole HPF filter 6 years ago HERE. The corner frequency is 18Hz and it has a roll off of -48dB/octave.

As a general rule, it is always better to remedy a condition that may be causing a problem rather than compensate for it after the fact. There is no way to eliminate the arm/cart resonance, but it can be "tuned" by changing the effective tone arm mass to match the cart's suspension. Damping the arm movement can sometimes reduce amount of oscillations but it can introduce other problems if not done correctly. There are on-line calculators to compute the arm/cart resonant frequency which may provide some insight.

Attachments

Thank you very much for fleshing out the details. That was a very complete answer! 🙂

I suspect the problem I'm having is the result of trying to shoehorn a modern, relatively high compliance cartridge onto an older, heavy-ish tonearm. The resulting tonearm/cartridge resonance is likely too high. The woofers 'pump' at about 10 times per second (10Hz), or rather quickly.

As a quick fix, I went ahead and purchased a Rod Elliott project 99 pcb and a couple of the project 05 psu pcbs. I'd rather avoid surface mount componentry for now.

I can see your HPF circuit is more advanced. Is there a serious downside to attempting to layout a pcb for that using through-hole components?

In the meantime I'll try to fix that tonearm/cartridge resonance. Having looked at balancing arm+headshell+cart weight against cartridge compliance, it always seems that the best one can do is reduce the arm+headshell+cart weight as much as possible (for a given cartridge compliance). I suppose the first thing to do is use the lightest possible headshell and see if that changes anything at all.

I suspect the problem I'm having is the result of trying to shoehorn a modern, relatively high compliance cartridge onto an older, heavy-ish tonearm. The resulting tonearm/cartridge resonance is likely too high. The woofers 'pump' at about 10 times per second (10Hz), or rather quickly.

As a quick fix, I went ahead and purchased a Rod Elliott project 99 pcb and a couple of the project 05 psu pcbs. I'd rather avoid surface mount componentry for now.

I can see your HPF circuit is more advanced. Is there a serious downside to attempting to layout a pcb for that using through-hole components?

In the meantime I'll try to fix that tonearm/cartridge resonance. Having looked at balancing arm+headshell+cart weight against cartridge compliance, it always seems that the best one can do is reduce the arm+headshell+cart weight as much as possible (for a given cartridge compliance). I suppose the first thing to do is use the lightest possible headshell and see if that changes anything at all.

Is there a serious downside to attempting to layout a pcb for that using through-hole components?

There is no reason it could not be done with TH components (the caps are all TH now). The PCB will be larger, but that is hardly a serious downside.

The response to the original thread was very thin, so I have no desire to redo the layout, nor do I have a lot of spare time on my hands. The thread included the schematic, so I encourage anyone with the skills to have a go at it. The layout could be simplified by replacing the 2 resistors to ground on each opamp section with a single resistor; I prefer to use standard 5% values which required multiple parts to get precise values, but it could be done with single 1% resistors.

Last edited:

LATER...

Well, that was easy.

I replaced the moving magnet cartridge with a lower compliance Denon DL103R that's been sitting on the shelf, waiting for me to install.

The woofer now moves only at exactly the point where there's a warp in the record. It's also not a wild and crazy motion, just a quick in/out when the stylus goes over the warp, i.e., reasonably well damped.

Well, that was easy.

I replaced the moving magnet cartridge with a lower compliance Denon DL103R that's been sitting on the shelf, waiting for me to install.

The woofer now moves only at exactly the point where there's a warp in the record. It's also not a wild and crazy motion, just a quick in/out when the stylus goes over the warp, i.e., reasonably well damped.

I've been following this thread, I went to Rod's website and purchased the filter PCB, one of the few times I will pay more for shipping than the item.

Thank you for sharing this.

You won't be sorry. Rod's subsonic filter is my go to high pass filter. It's very effective and does not affect audible frequencies.

It is true that it doesn't have the classic "ideal" response, but in this application it doesn't matter at all. That becomes an issue in an active crossover or equalizer circuit.

- Home

- Source & Line

- Analogue Source

- Very low frequency vibrations in belt turntables.