Hello all, before I say another word, I want to trigger warn those of you who are cable-sensitive and prone to hysterical and emotional outbursts to stop now and read something else. This question and thread is going to involve explicit discussions of FOIL, COPPER, DIELECTRIC, and other audio related terms that may upset those with tender nervous systems.

So, I'll soon be building a new set of foil speaker cables, and I'm up against one question, and that is whether to laminate the foils together with a thin dielectric strip isolating the two individual foils, or separating them, and if so, by how much. I'll lay out the three possible architectures, and would really like to hear from anyone WHO HAS EXPERIENCE WITH FOIL CABLES. I've enough cable theory (much of it way over my head) to have a headache for several weeks, and although I learned a bunch of things, my conclusion is there is no agreement, and engineers still argue based on their own determination of which are the most important electrical parameters to focus on. I have come to realize cable science is very very complicated. Some people think the inductance-capacitance relationship is everything, while others downplay it, and instead focus on DCR or phase alignment. It goes on and on.

I'm not using the typical tape method, instead the foils will be bare, with a micro thin layer of protectant in order to stave off oxidization.

Here are the three design ideas I'm considering for these foils:

1. Typical Allen Wright/Goertz design, where the two conductors are separated by the thinnest strip of DE, such as teflon or polypropelene tape. It could be stuck to the foils or just laid in, sparating the foils just a bit more.

2. a variation, substituting woven cotton in place of the PTFE, creating a gap of approx 1mm. This lowers C a bit, raises L, but also introduces more air/cotton as the DE, which I see as an advantage.

3. separate the foils entirely, each sheathed in cotton surgical tubing, then the pair wrapped together in PET sleeving, OR entirely separate, each its own complete assembly, wrapped first in the cotton, then the PET.

I'm using the cotton because it's an excellent DE material, and also, being a bit loose, allows there to be more air around the conductor. I've built cables like this before, and I'm very pleased with the results. The PET Techflex is for appearance, and also to give the whole thing some body and added stiffness to the delicate foil.

That's it! Thanks for reading, and I hope this can lead to a fruitful conversation. Again, please, if you don't have a real contribution to make, just go somewhere else and flame away.

Bryan

So, I'll soon be building a new set of foil speaker cables, and I'm up against one question, and that is whether to laminate the foils together with a thin dielectric strip isolating the two individual foils, or separating them, and if so, by how much. I'll lay out the three possible architectures, and would really like to hear from anyone WHO HAS EXPERIENCE WITH FOIL CABLES. I've enough cable theory (much of it way over my head) to have a headache for several weeks, and although I learned a bunch of things, my conclusion is there is no agreement, and engineers still argue based on their own determination of which are the most important electrical parameters to focus on. I have come to realize cable science is very very complicated. Some people think the inductance-capacitance relationship is everything, while others downplay it, and instead focus on DCR or phase alignment. It goes on and on.

I'm not using the typical tape method, instead the foils will be bare, with a micro thin layer of protectant in order to stave off oxidization.

Here are the three design ideas I'm considering for these foils:

1. Typical Allen Wright/Goertz design, where the two conductors are separated by the thinnest strip of DE, such as teflon or polypropelene tape. It could be stuck to the foils or just laid in, sparating the foils just a bit more.

2. a variation, substituting woven cotton in place of the PTFE, creating a gap of approx 1mm. This lowers C a bit, raises L, but also introduces more air/cotton as the DE, which I see as an advantage.

3. separate the foils entirely, each sheathed in cotton surgical tubing, then the pair wrapped together in PET sleeving, OR entirely separate, each its own complete assembly, wrapped first in the cotton, then the PET.

I'm using the cotton because it's an excellent DE material, and also, being a bit loose, allows there to be more air around the conductor. I've built cables like this before, and I'm very pleased with the results. The PET Techflex is for appearance, and also to give the whole thing some body and added stiffness to the delicate foil.

That's it! Thanks for reading, and I hope this can lead to a fruitful conversation. Again, please, if you don't have a real contribution to make, just go somewhere else and flame away.

Bryan

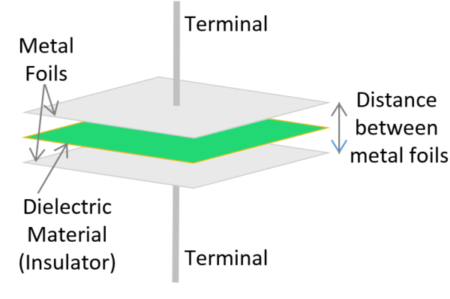

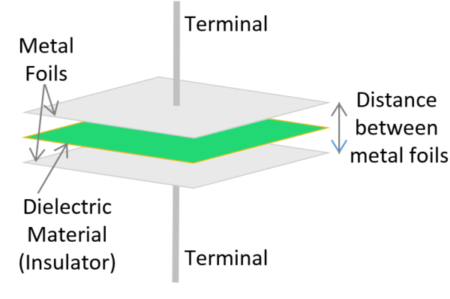

2 looonnnngggg high surface metal sheets, in close proximity?

That´s a CAPACITOR, and a large one, your amplifier won´t like it a bit.

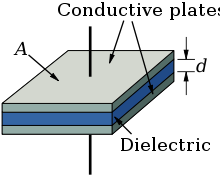

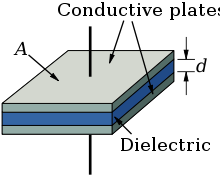

Your description meets the Capacitor definition to a t:

.

It is so much a capacitor, that if you give us foil length, width, separation and dielectric we can easily calculate its capacitance with high precision, go figure.

Why would anybody load his amplifier with a large capacitor, on purpose, is beyond me.

.

Your "cable" amounts to:

You´ll recognize it better if you see it this way, ring a bell?

That´s a CAPACITOR, and a large one, your amplifier won´t like it a bit.

Your description meets the Capacitor definition to a t:

.

It is so much a capacitor, that if you give us foil length, width, separation and dielectric we can easily calculate its capacitance with high precision, go figure.

Why would anybody load his amplifier with a large capacitor, on purpose, is beyond me.

.

Your "cable" amounts to:

You´ll recognize it better if you see it this way, ring a bell?

1. Why? Tell us the perceived advantage, your thoughts as to the choice of foil cables over normal zip cord and its siblings.

2. That stuff tends to be fragile, so think of supporting the foil in a proper long term way.

3. Search this and other forums, you may find someone tried it earlier. Learn from that.

And find a source of copper foil in the meantime, it comes in many thicknesses, and different hardness types.

2. That stuff tends to be fragile, so think of supporting the foil in a proper long term way.

3. Search this and other forums, you may find someone tried it earlier. Learn from that.

And find a source of copper foil in the meantime, it comes in many thicknesses, and different hardness types.

I have seen copper foil used for long loudspeaker runs. It was in a very large masonry church. They ran two pieces of foil about 2” apart flat along the top of the wall in the hall. That was painted over and ran to the remote loudspeakers. The foil is .020” thick and .5” wide. The run is about 250’.

The original amplifier driving this was a Western Electric model.

Very advanced system for 1935.

The acoustician was Paul Sabine.

I do keep a roll of foil around for such uses. It is available from McMaster Carr.

The original amplifier driving this was a Western Electric model.

Very advanced system for 1935.

The acoustician was Paul Sabine.

I do keep a roll of foil around for such uses. It is available from McMaster Carr.

Last edited:

I'm not an expert, or an EE, just someone exploring this audio world like many of you here.

First, I have used lots of different cables, and the set of foils I now have in my system are the best sounding so far. I've used Belden 10 ga zipwire as well, and it was very good.

My tube amp doesn't give a **** about capacitance, so can JM Fahey tell me what is wrong with high C and low inductance?

There is such a focus on the C/L ratio in speaker cables, what about impedance, and the difference that it could make to have the lowest possible?

Do you JM Fahey have such complete knowledge of everything that you can so assuredly post sarcastic comments?

Please tell me exactly why high C is such a problem with speaker cables, in a tube driven system and I will listen. This is not ICs we're talking about.

And for those of you who just see a chance to score performative points to your illusory audience, get a life, use your real name, it looks cowardly and unbecoming of grown men.

Maybe we can turn this into a useful and educational thread, does someone have more than derision to offer?

First, I have used lots of different cables, and the set of foils I now have in my system are the best sounding so far. I've used Belden 10 ga zipwire as well, and it was very good.

My tube amp doesn't give a **** about capacitance, so can JM Fahey tell me what is wrong with high C and low inductance?

There is such a focus on the C/L ratio in speaker cables, what about impedance, and the difference that it could make to have the lowest possible?

Do you JM Fahey have such complete knowledge of everything that you can so assuredly post sarcastic comments?

Please tell me exactly why high C is such a problem with speaker cables, in a tube driven system and I will listen. This is not ICs we're talking about.

And for those of you who just see a chance to score performative points to your illusory audience, get a life, use your real name, it looks cowardly and unbecoming of grown men.

Maybe we can turn this into a useful and educational thread, does someone have more than derision to offer?

A description of your system would have been useful.

Even different tubes may have different responses to capacitive and parasitic loads.

I am Naresh, from Baroda (also known as Vadodara), and you can look up my full name, nothing hidden.

I hope you did not find my comments offensive.

0.020" is about 0.5 mm, and 0.5" is about 13 mm...thick for a foil, I thought it would be about 0.1 mm thick, or about 0.004". That is not a fragile foil.

Protection from oxidization, I would paint it over with a durable paint, which is flexible, see if marine grade rubber paint has suitable properties.

Even different tubes may have different responses to capacitive and parasitic loads.

I am Naresh, from Baroda (also known as Vadodara), and you can look up my full name, nothing hidden.

I hope you did not find my comments offensive.

0.020" is about 0.5 mm, and 0.5" is about 13 mm...thick for a foil, I thought it would be about 0.1 mm thick, or about 0.004". That is not a fragile foil.

Protection from oxidization, I would paint it over with a durable paint, which is flexible, see if marine grade rubber paint has suitable properties.

Last edited:

Why bother to answer? You clearly stated that you didn't want to talk science but rather the color of the wrap.I'm not an expert, or an EE, just someone exploring this audio world like many of you here.

First, I have used lots of different cables, and the set of foils I now have in my system are the best sounding so far. I've used Belden 10 ga zipwire as well, and it was very good.

My tube amp doesn't give a **** about capacitance, so can JM Fahey tell me what is wrong with high C and low inductance?

There is such a focus on the C/L ratio in speaker cables, what about impedance, and the difference that it could make to have the lowest possible?

Do you JM Fahey have such complete knowledge of everything that you can so assuredly post sarcastic comments?

Please tell me exactly why high C is such a problem with speaker cables, in a tube driven system and I will listen. This is not ICs we're talking about.

And for those of you who just see a chance to score performative points to your illusory audience, get a life, use your real name, it looks cowardly and unbecoming of grown men.

Maybe we can turn this into a useful and educational thread, does someone have more than derision to offer?

With your thread introduction I don't see how one can add anything really.

This forum is, as I see it, a mostly technology oriented place. You will get much more color suggestions elsewhere but you will miss the wisdom of poster like JM.

Educational - like color therapy insights education?

Good luck with your capacitors!

//

Hi Naresh, the foils are Mundorf copper, same stuff they use in their inductors. It's .07mm thick, so pretty easy to kink or stress-tear, especially near the connection points.A description of your system would have been useful.

Even different tubes may have different responses to capacitive and parasitic loads.

I am Naresh, from Baroda (also Vadodara), and you can look up my real name, nothing hidden.

I hope you did not find my comments offensive.

0.020" is about 0.5 mm, and 0.5" is about 13 mm...thick for a foil, I thought it would be about 0.1 mm thick, or about 0.004". That is not a fragile foil.

Protection from oxidization, I would paint it over with a durable paint.

I have definitely experienced trouble with high C cables in the past, with my class A SS amp. It was scary. I never tried foils with that amp, but Kimber 8TC was a no-go, as were heavy solid cables (Anticables, basically bare varnished cable twisted together). But in my current set up, the foils I'm using sound very good to me. They are clear, with very solid bass response, and no sign of rolloff, quite detailed. I've messed around enough to know that all cables are filters of one sort or another, and the game is all about tradeoffs.

Having tried to read as many papers as I can written by real life cable designers, I realize the science is way, way more complex than I'm capable of understanding. I also realized that the common, reductive approach just going on about a couple of parameters (CLR), which are of course important and real variables, but maybe not the whole picture. Reading Galen Gareis's (Belden, iconoclast) story was something that really opened my eyes, a guy who has spent his whole life in cable design, who dared to step into subjective territory. Courageous move. The thing that struck me was he concluded that different cables with identical CLR numbers could sound very distinct from each other. I can't follow his writings too far, but he's definitely shown that there are other factors in play, especially those that affect timing - impedance, reflections, group delay, blabla.

So yeah, my foils are high C, but they sound great to me. I'm just trying to evolve the design a bit and see where it goes.

Thanks for the idea about the paint. I'm going to use microcrystalline wax.

My system is Streamer/Audiolab CDT6000 - Requisite Audio silver/silver copper IC's-Schiit Bifrost 2/64 - evil foils - stand mounts with RAAL 70/20 and Satori MW (DIY, Jeff Bagby Auricle design)

Bryan

Last edited:

Back in the day I used to draw for my father, an electrical engineer, who designed for buildings. We once had a guy try to sell us on an under carpet cable system for open concept offices. The conductors were side by side. Trouble was it was designed to be used under carpet tile (which our architects never specified) and was really only good for straight runs of desks. I still have a short sample piece of it in a box in the basement.

www.alldataresource.com/Power-Cables_c_5081.html

www.alldataresource.com/Power-Cables_c_5081.html

Attachments

Last edited:

There are several manufacturers of flat ribbon conductor speaker cables on the market. Alpha Core Goertz was very popular for a while. There are others if you search. I made a pair of silver foil Goertz style speaker cables about 20 years ago and used them without any issues with my Spectron Musician III class d amp and Gallo Nucleus speakers. I still have them somewhere. With the price of silver where it is now, they are probably worth many times what I paid. For those who say there are no advantages with silver cables, let me say that capital appreciation is real, lol...

Maybe one could just unwind a capacitor and use the foil for the project. 😝

One certainly could but it's not very cost efficient. Copper caps tend to be expensive and the foil thin. Foil inductors are the obvious cheap source.

Even cheaper is to just buy the foil - Mundorf sells 10 meter rolls for $10-$25, depending on width. Takes some of the sting out if they're a fail, and would look good on the Christmas Tree.One certainly could but it's not very cost efficient. Copper caps tend to be expensive and the foil thin. Foil inductors are the obvious cheap source.

I'm not using the typical tape method, instead the foils will be bare, with a micro thin layer of protectant in order to stave off oxidization.

Good. I used foil cables more that 20 years ago. Different system, different priorities. Used tape and in a few years the copper went green.

Did not find a big difference in sound when the two lengths were widely separated or running close together. Perhaps many nfb amps will prefer high inductance to high capacitance.

Either way the sound was lightning fast with very clear transients but also a bit bass light and threadbare. Liked it in the beginning but it grew tiresome fast.

Even cheaper is to just buy the foil - Mundorf sells 10 meter rolls for $10-$25, depending on width. Takes some of the sting out if they're a fail, and would look good on the Christmas Tree.

Thanks for this, did not know. I still break inductors whenever i need copper strips.

Is that it?

https://www.audiophonics.fr/en/hook...-flat-wiring-cable-70x007mm-49mm-p-12371.html

I experimented a lot with foil cables and ended up having them dialated by 4mm, cotton dielectric and cotton in dialation, and wrapped with ptfe and all slieved in heatshrink. That provided me with the least capacitance and best sounding cable. Terminated by Viborg bananas. I tried also laying conductors next to each other on it sides, but it was not satisfactory to me. Do note that using thin dielectric/small dialation does make it have significant capacitance which will most likely throw your amp in oscilation.

And yeah, after going foil cable route, not going back 🙂

And yeah, after going foil cable route, not going back 🙂

Yes, and also here: https://www.hificollective.co.uk/wire/mundorf-copper-foil.htmlThanks for this, did not know. I still break inductors whenever i need copper strips.

Is that it?

https://www.audiophonics.fr/en/hook...-flat-wiring-cable-70x007mm-49mm-p-12371.html

Thanks Brijac, this sounds very much like what I plan to do. When you say dialated, I think you mean "separated", is this right? I'm planning either to wrap each foil in cotton tubing, or simply separate the two foils with a strip of the same cotton tubing, which is pretty thick: https://www.hificollective.co.uk/sleeving/cotton-tubing.htmlI experimented a lot with foil cables and ended up having them dialated by 4mm, cotton dielectric and cotton in dialation, and wrapped with ptfe and all slieved in heatshrink. That provided me with the least capacitance and best sounding cable. Terminated by Viborg bananas. I tried also laying conductors next to each other on it sides, but it was not satisfactory to me. Do note that using thin dielectric/small dialation does make it have significant capacitance which will most likely throw your amp in oscilation.

And yeah, after going foil cable route, not going back 🙂

I currently have foils separated only by a thin layer of polypropelene tape, but want to reduce the capacitance a bit. I haven't had oscillation issues but I think the high capacitance is probably too extreme and causing other issues.

I"m glad to hear you've had success with similar designs. Viborg make very nice stuff.

Last edited:

Yes, separated. Mine are wrapped in 2mm thick cotton, several layers. So it dialates them by 4mm in total. I bought it as unprocessed cotton canvas in a local store that deals with fabric.

- Home

- Design & Build

- Construction Tips

- Foil Cable design